Fuel cell cathode side humidity adjustment control system and method

A fuel cell cathode and humidity adjustment technology, which is applied in the direction of fuel cell control, fuel cells, fuel cell additives, etc., can solve the problems of fuel cell loss, untimely adjustment, battery external equipment to reduce battery load, etc., to reduce loss, The effect of improving detection accuracy and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

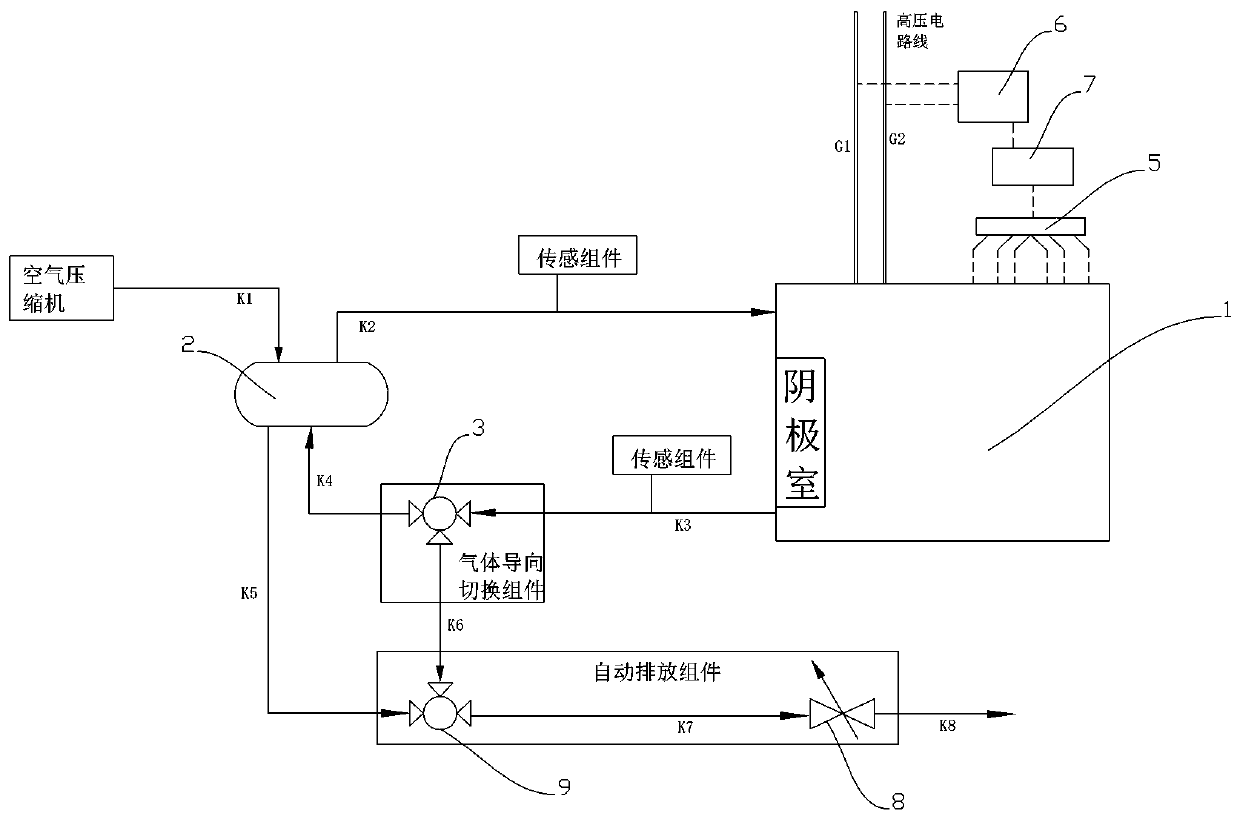

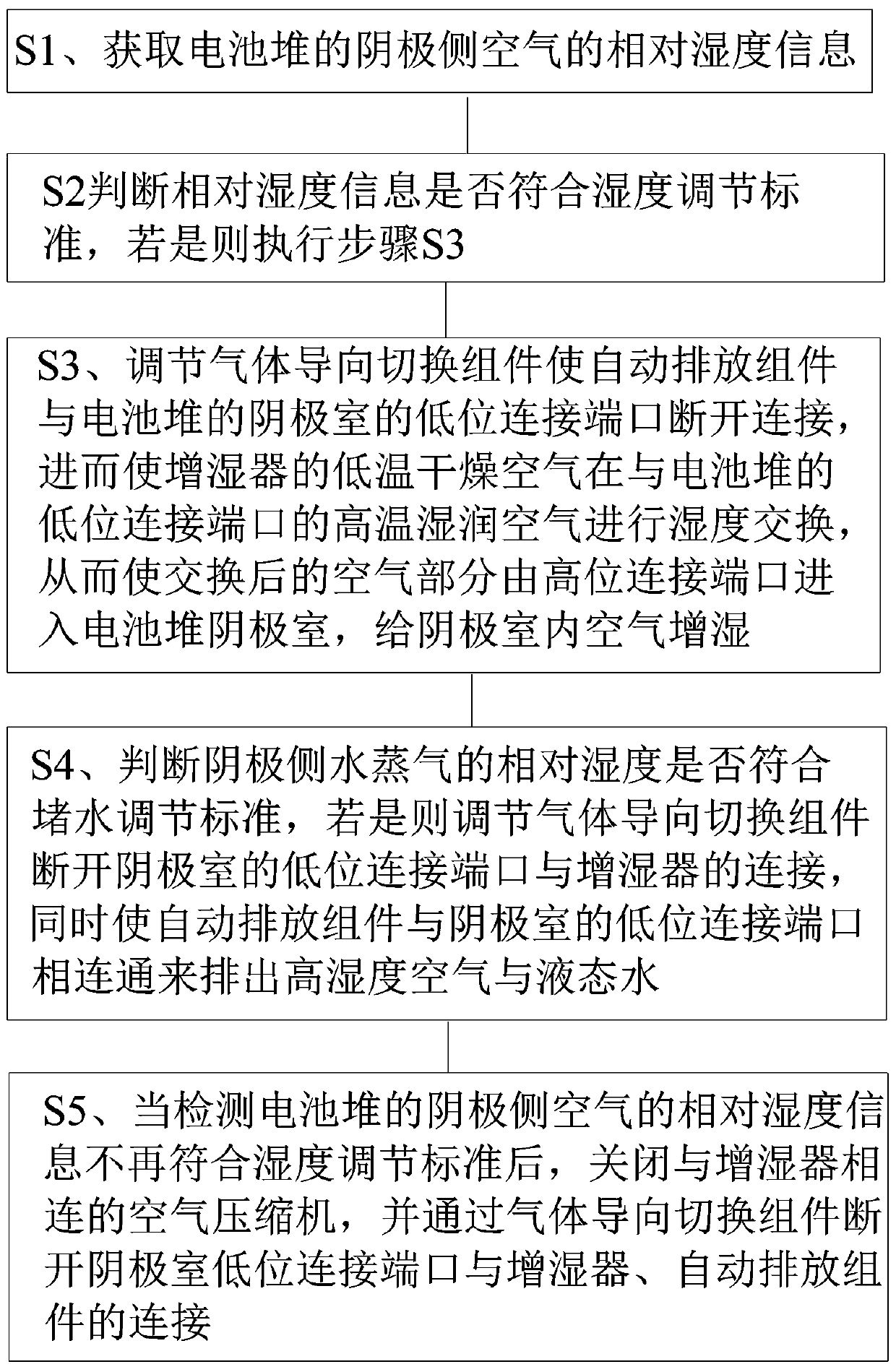

[0045] Such as figure 1 As shown, this embodiment provides a specific usage method including steps ① to ⑥.

[0046] ①Reference Figure 1 , the low-temperature dry air enters the humidifier 2 through the air duct K1 after being pressurized by the air compressor.

[0047] ②The high temperature and humid air in the cathode chamber of the cathode side of the fuel cell stack 1 enters the humidifier 2 through the air pipeline K3, the first electromagnetic three-way valve 3 and the air pipeline K4. At this time, the section of the air pipeline K3 to K4 is unblocked, and the air pipeline K3 to K6 Road segment closed.

[0048] ③The temperature and humidity exchange between low-temperature dry air and high-temperature humid air is completed in the humidifier 2. The temperature and humidity of the original low-temperature dry air rise and enter the fuel cell stack 1 through the air duct K2. The temperature and humidity of the original high-temperature humid air After being lowered, th...

Embodiment 2

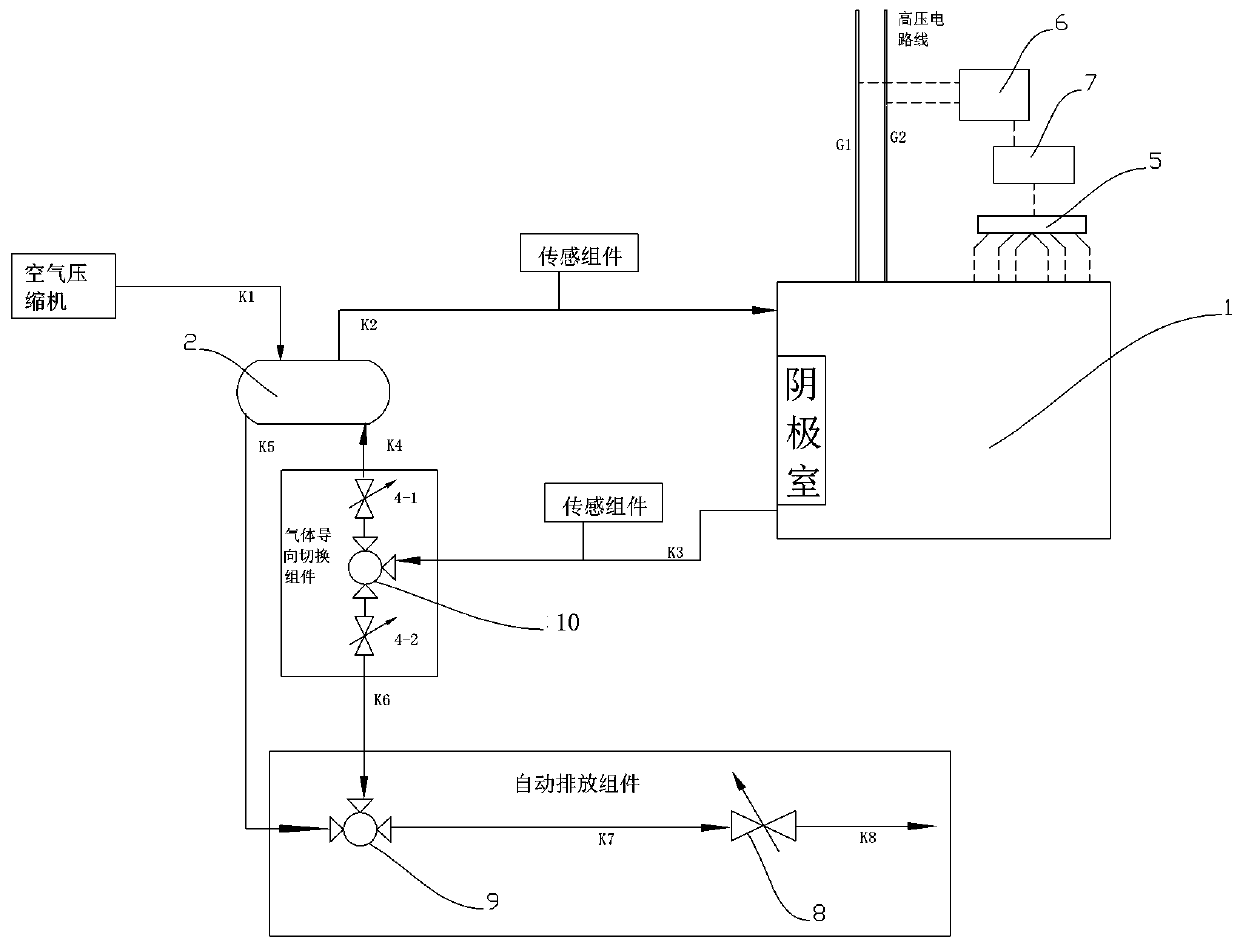

[0055] Such as figure 2 As shown, the general use steps of embodiment 2 are similar to those of embodiment 1, except that the system of embodiment 2 is provided with a first throttle valve 4-1 and a second damper 4-1 on the air pipe connected to the humidifier 2 and the automatic discharge assembly respectively. The throttle valve 4-2 replaces the first electromagnetic three-way valve 3 with the normally open first pilot three-way valve 10 simultaneously. Among them, the first throttle valve 4-1 and the second throttle valve 4-2 are logically interlocked, and if any one is opened, the other one must be closed; in addition, for the convenience of control, the throttle valve states are only open and closed, and there is no The intermediate state of the opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com