Flying dust eliminating device for concrete mixer on basis of green building construction site

A technology for concrete mixers and construction sites, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separating agents, etc., which can solve the problems of easy generation of dust, inconvenient dust recovery, and easy diffusion of dust, so as to increase convenience and improve Dust suppression effect, effect of suppressing the spread of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

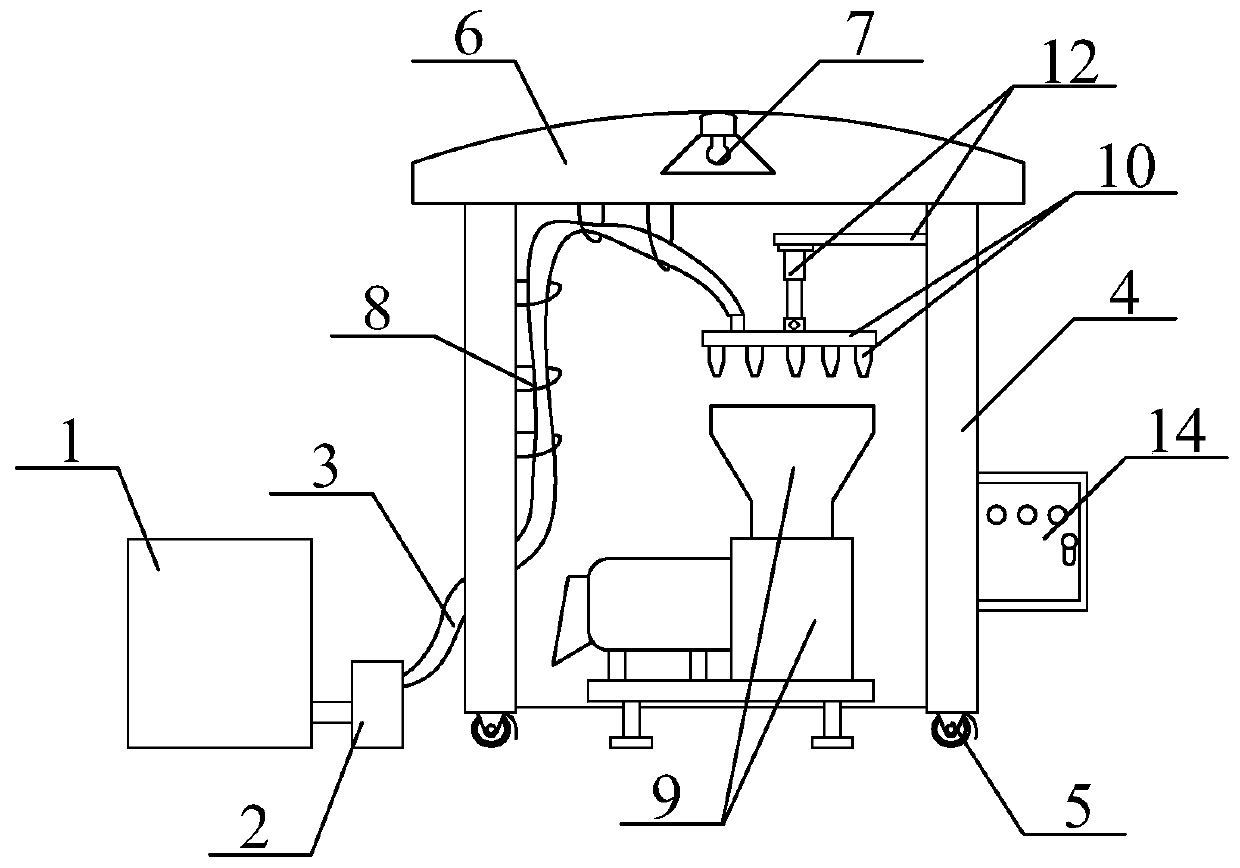

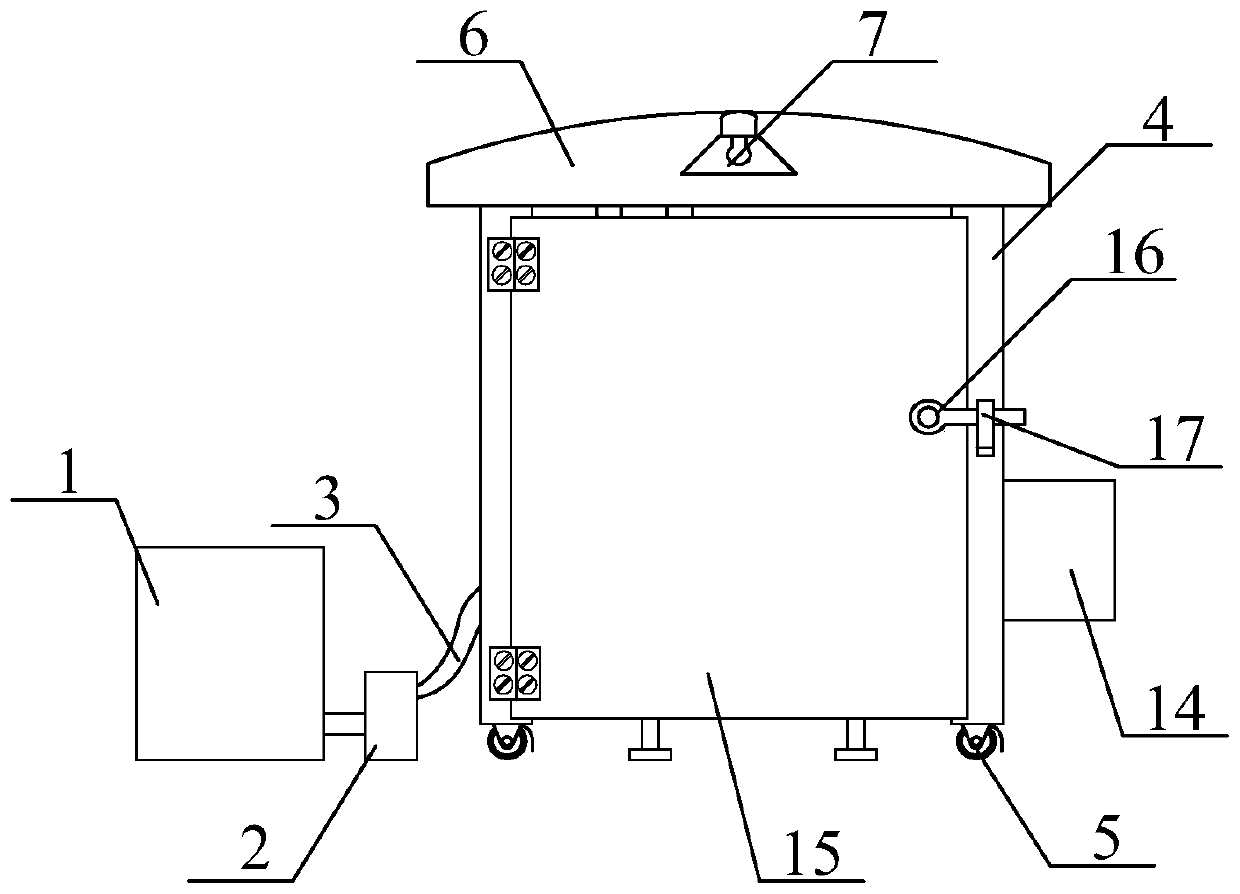

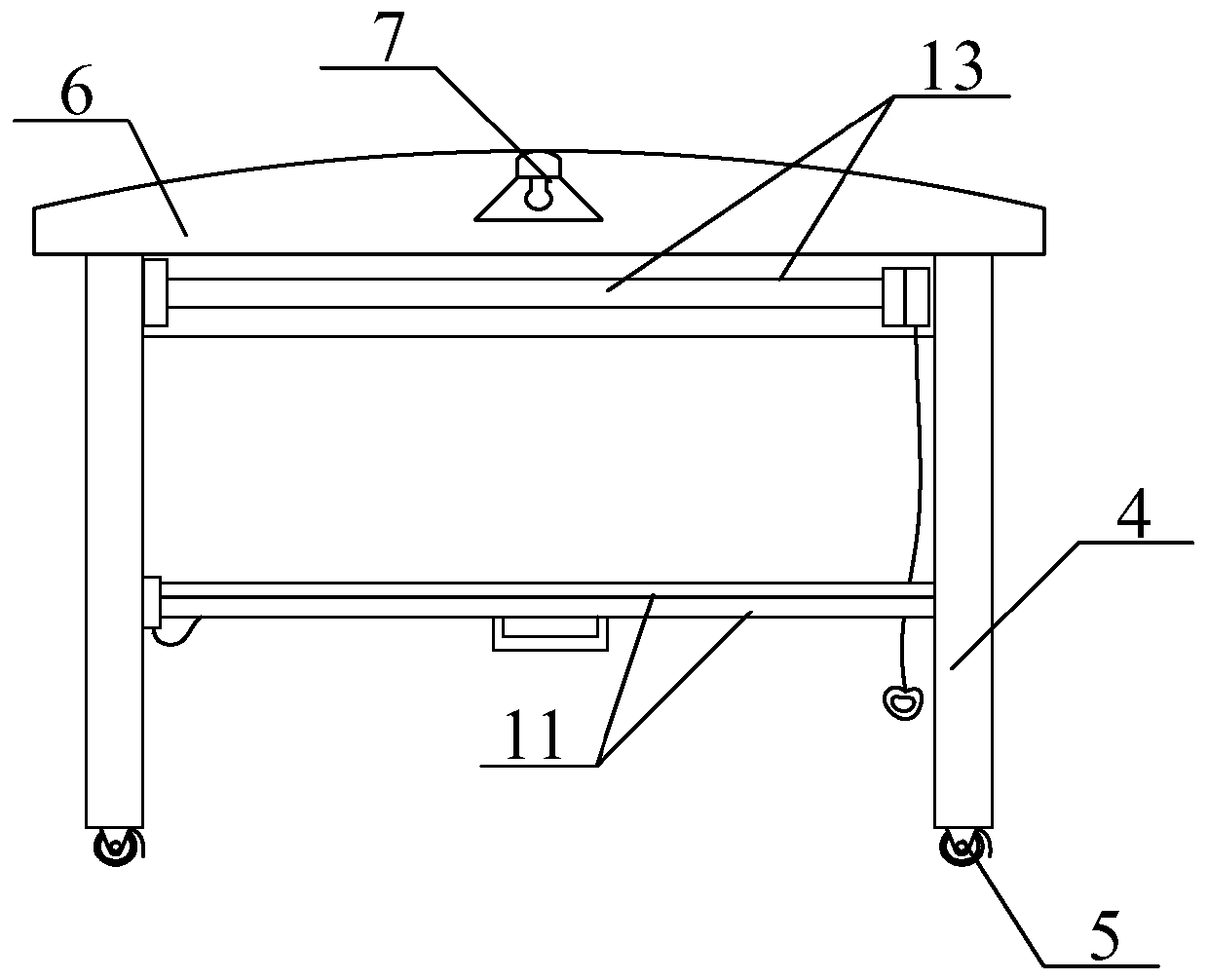

[0036] as attached figure 1 To attach Figure 4As shown, the present invention provides a dust removal device based on a green building construction site concrete mixer, including a water storage tank 1, a water pump 2, a diversion spray pipe 3, a support column 4, a moving wheel 5, a dust cover 6, and a lighting lamp 7 , limit spring ring 8, concrete mixer main body 9, dust removal spray plate structure 10, side dust collection bucket structure 11, liftable boom rod structure 12, dust diffusion prevention curtain structure 13, control box 14, rear dust cover door 15, sealing handle 16 and L-shaped buckle 17, the pipeline of the water pump 2 is connected to the lower right side of the water storage tank 1; end and pass through the inside of the limit spring coil 8 to connect with the dust removal spray plate structure 10; one end of the support column 4 is respectively bolted to the four corners of the lower surface of the dust cover 6, and the other end is bolted to the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com