Device for detecting abnormality in attachment of tool

A cutting tool and abnormal technology, applied in positioning devices, manufacturing tools, measuring/indicating equipment, etc., can solve problems such as difficulty in detecting the abnormal state of tool installation and inability to fully hold the tool holder, so as to suppress costs and reduce work errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

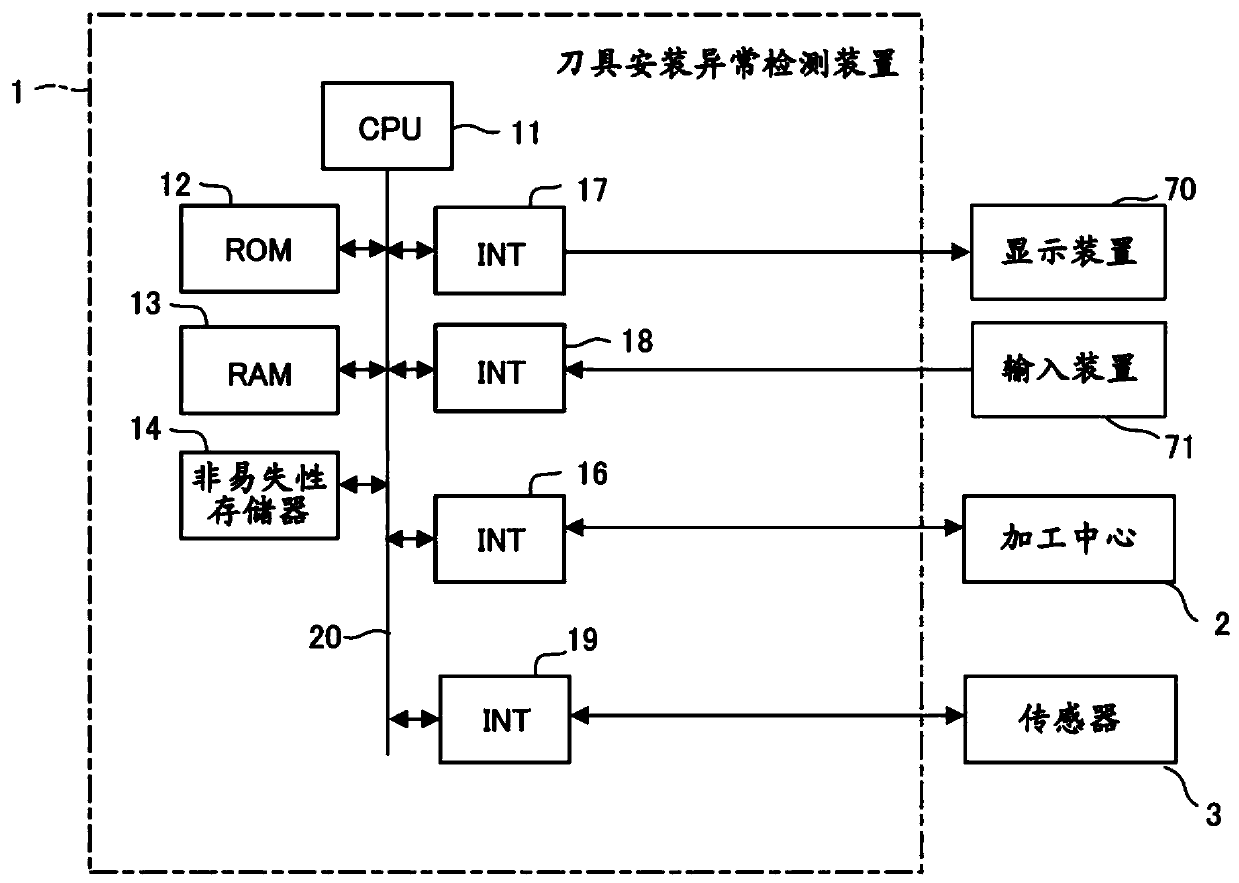

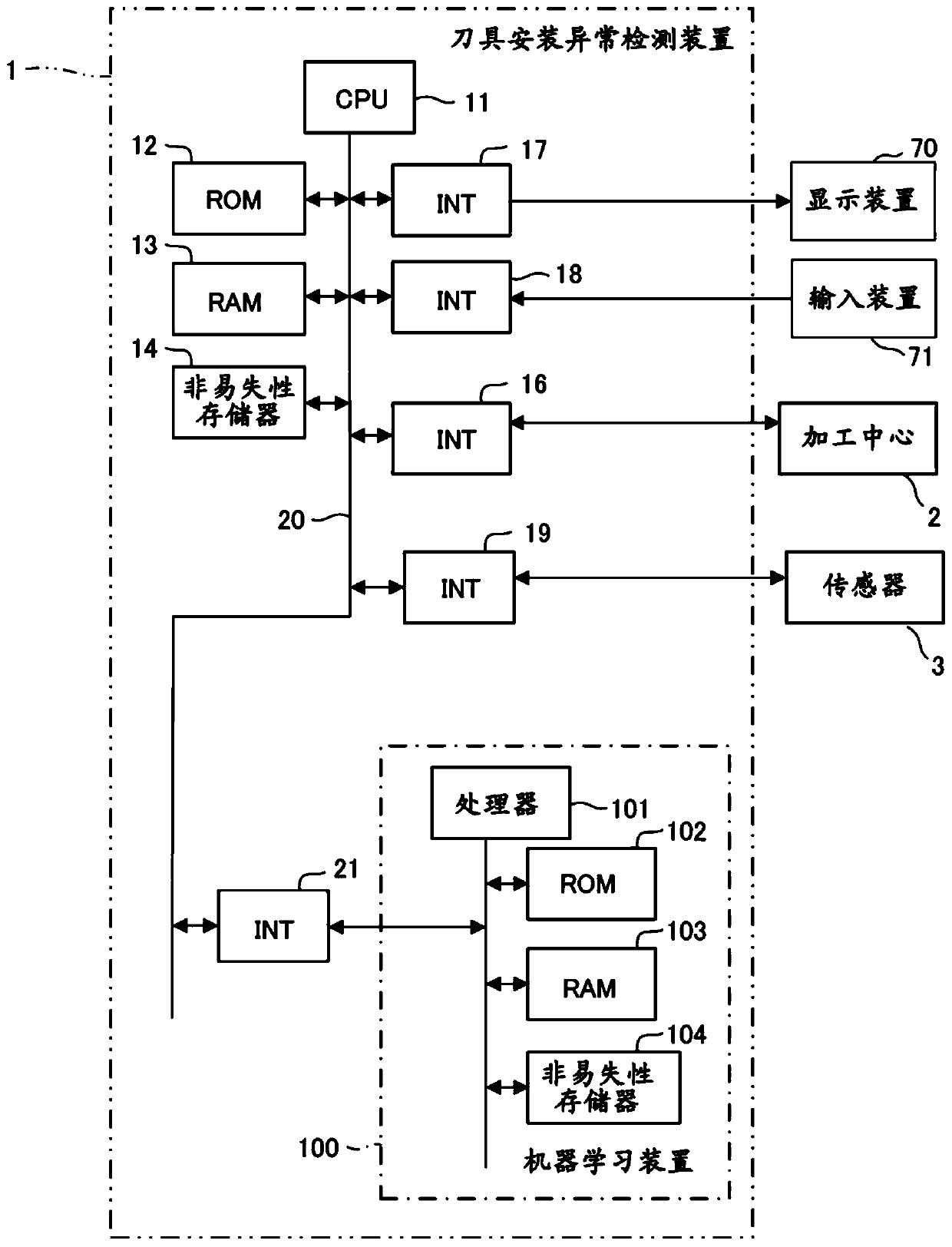

[0025] below, with Figure 1 Embodiments of the present invention will be described below.

[0026] figure 1 It is a schematic hardware configuration diagram showing main parts of the device for detecting abnormality in tool mounting (tool mounting abnormality detection device, ie, device 1 ) including the machine learning device of the first embodiment. The device 1 of the present embodiment can be mounted, for example, on a control device that controls the machining center 2 . In addition, the device 1 of the present embodiment can be implemented as a personal computer installed side by side with a control device for controlling a machining center, an edge computer connected to the control device via a wired / wireless network, a cell computer, a host computer, a cloud server, or other computers. . In this embodiment, an example of the case where the device 1 is installed as a personal computer installed in parallel with a control device for controlling the machining center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com