Portable fiber splicing worktable

An optical fiber fusion splicing and workbench technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of reducing work accuracy, prone to errors, and increasing difficulty, so as to reduce work errors, improve work efficiency, and facilitate welding operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

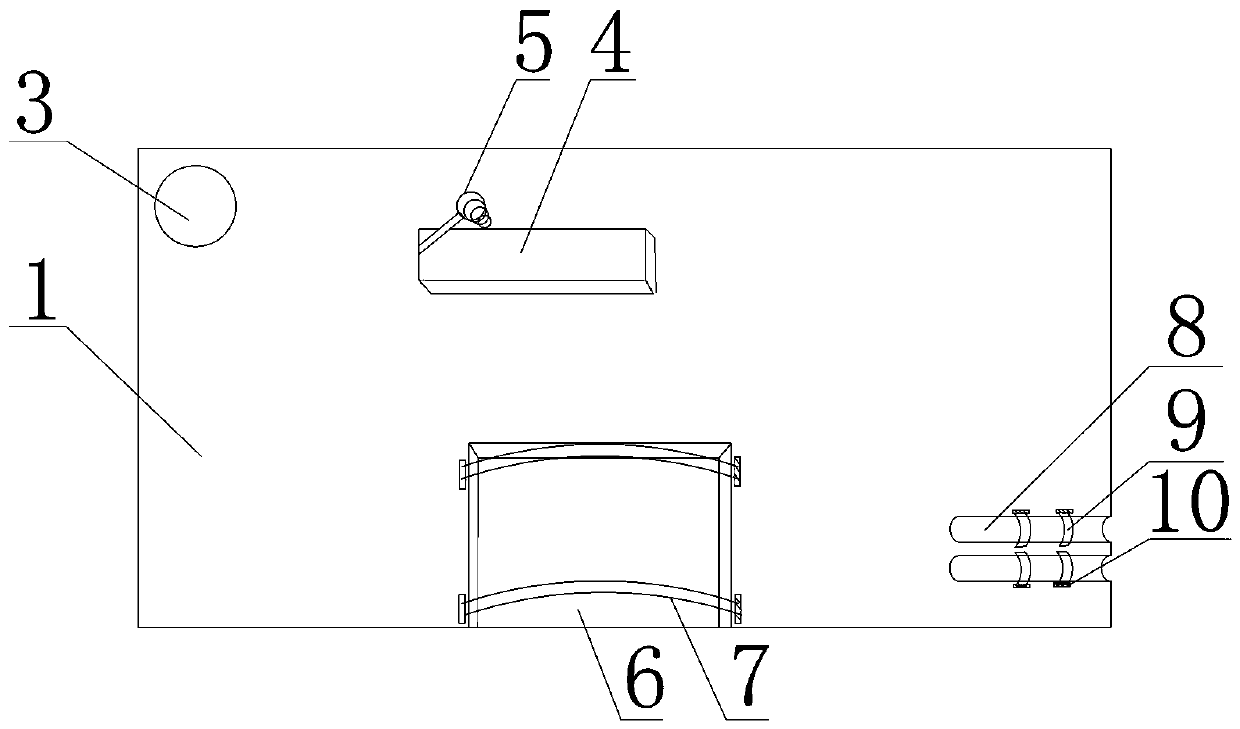

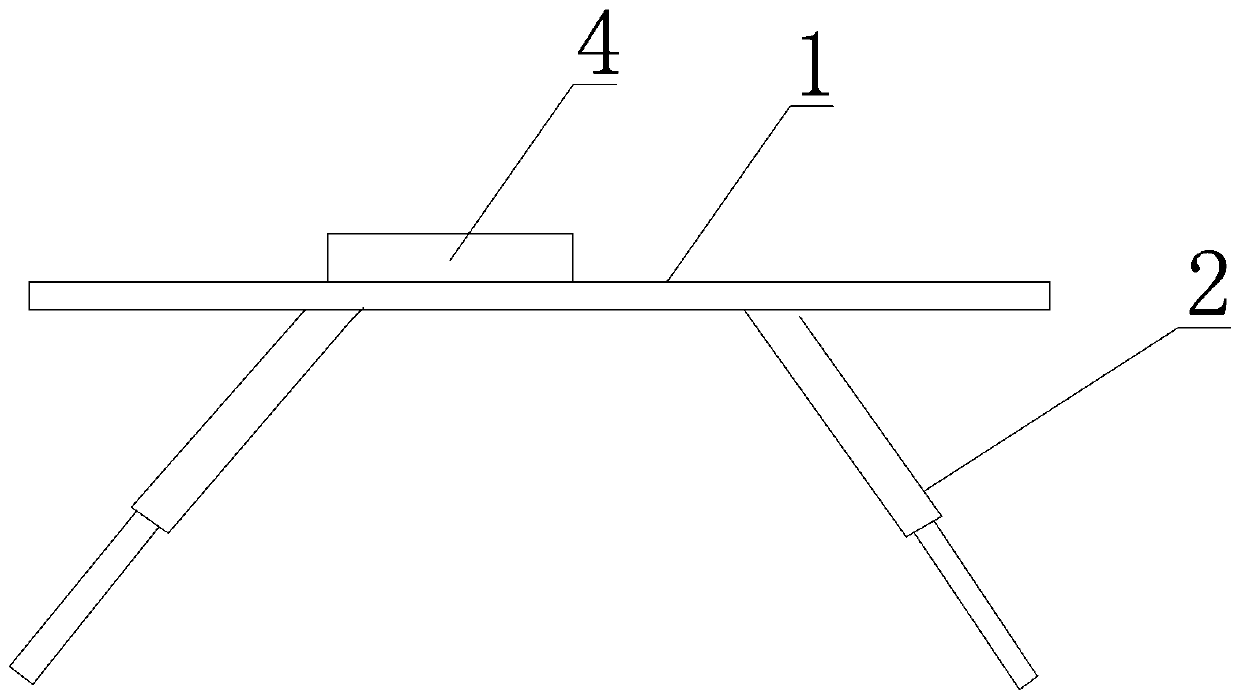

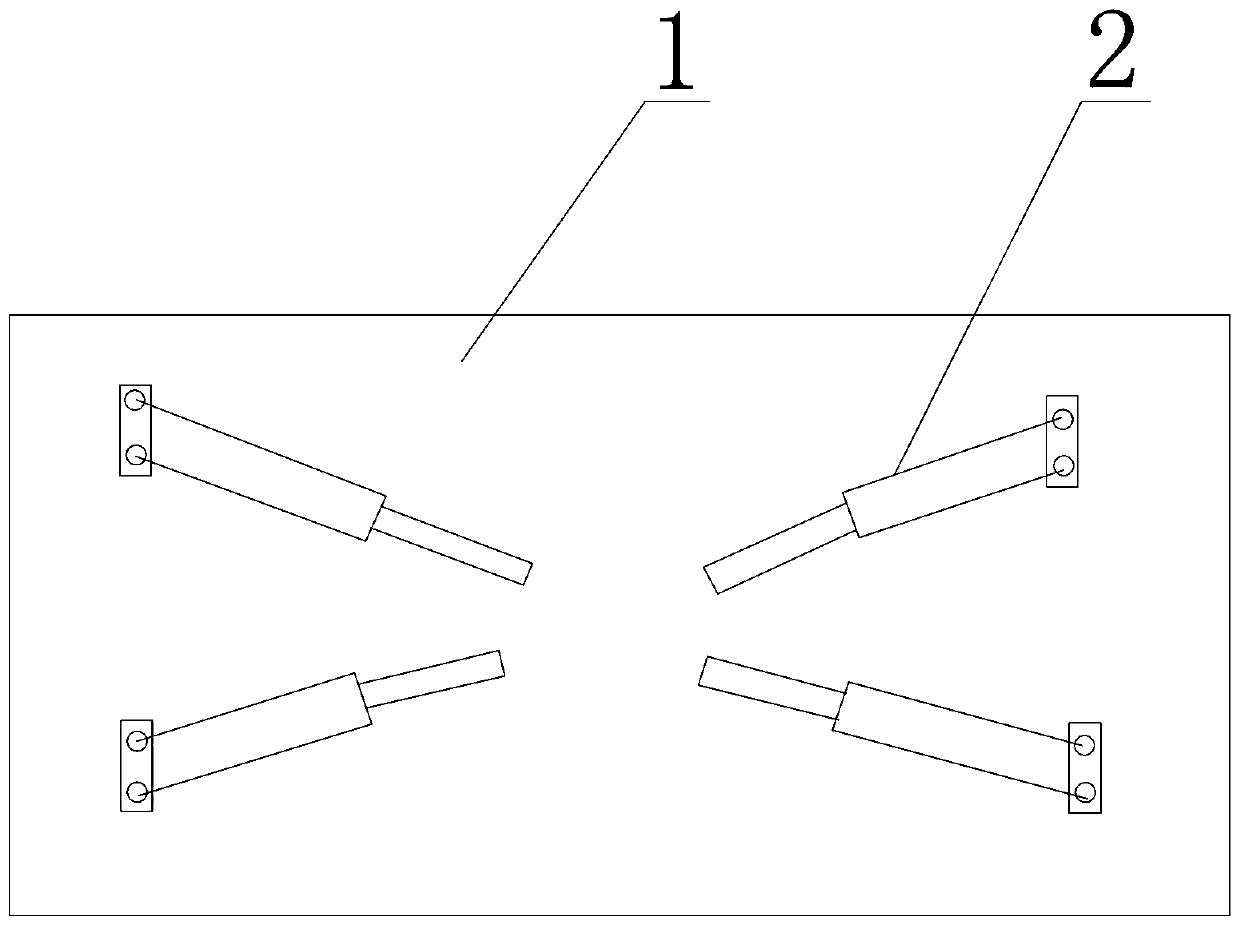

[0015] Such as figure 1 , figure 2 and image 3 As shown, a portable optical fiber fusion splicing workbench includes a desktop 1 and four foldable table legs 2 arranged at the bottom of the desktop 1. The upper part of the desktop 1 is respectively provided with a lamp groove 3 for placing a desk lamp, a welding boss 4, The fiber optic box placement groove 6 and the optical cable fixing groove 8 corresponding to the fiber optic box placement groove 6 are provided. The welding boss 4 is also provided with a spring coil 5 for placing an electric soldering iron. One of the fiber optic cable fixing grooves 8 At least two cable fixing bands 9 are arranged on one side, and the ends of the cable fixing belts 9 are provided with fixing plugs, and the other side of the cable fixing groove 8 is provided with fixing slots 10 corresponding to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com