Method for determining steel loading time and preventing hot-fed billet from damaging casthouse equipment

A billet and steel loading technology, which is applied in the field of preventing hot billets from damaging the furnace equipment, can solve problems such as inability to swing, increase equipment costs, and inability to apply the positioning roller table in front of the furnace, so as to reduce the interruption time of steel loading and prolong the service life , Improve the effect of automatic control operation rate of steel loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

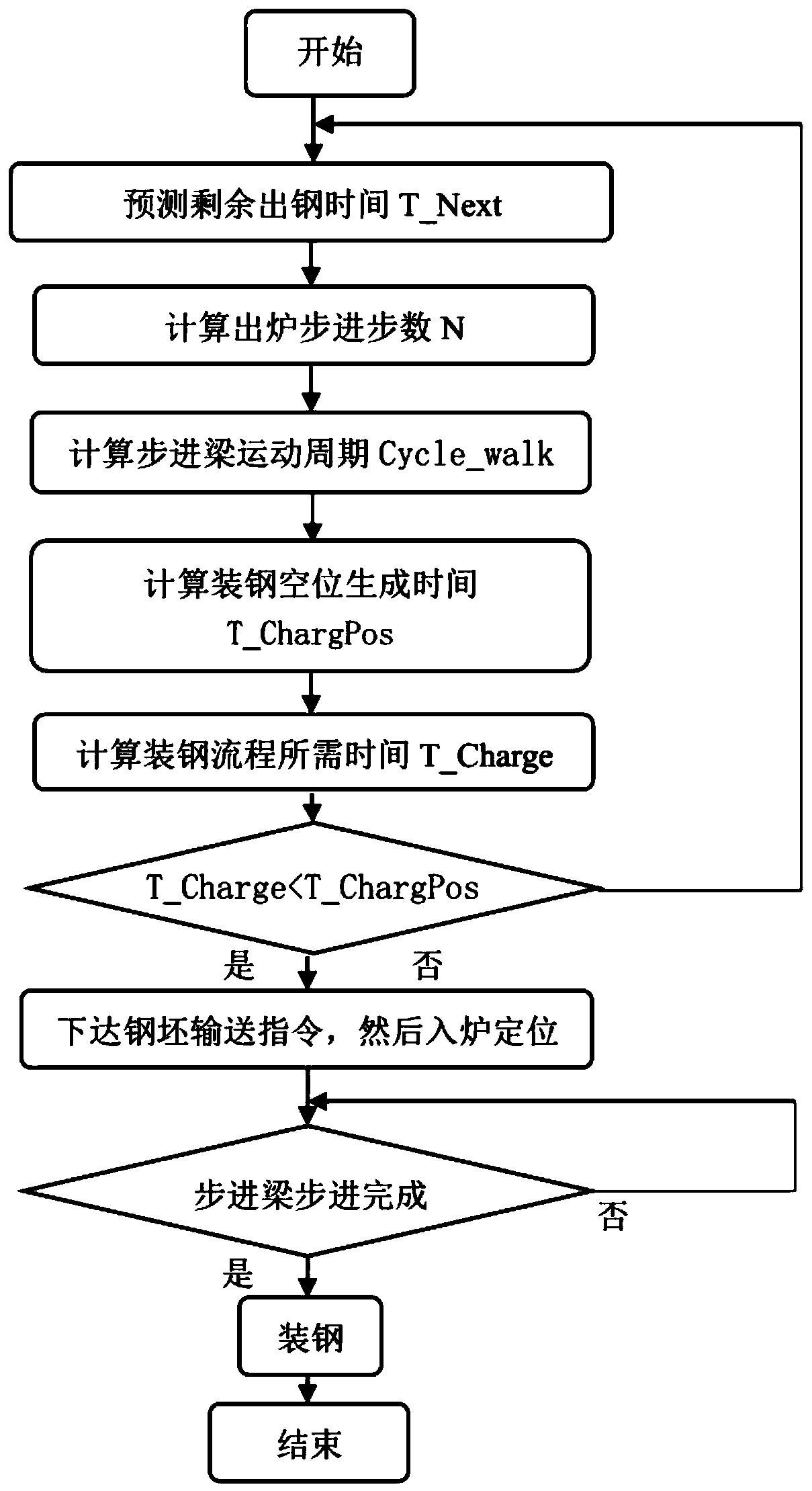

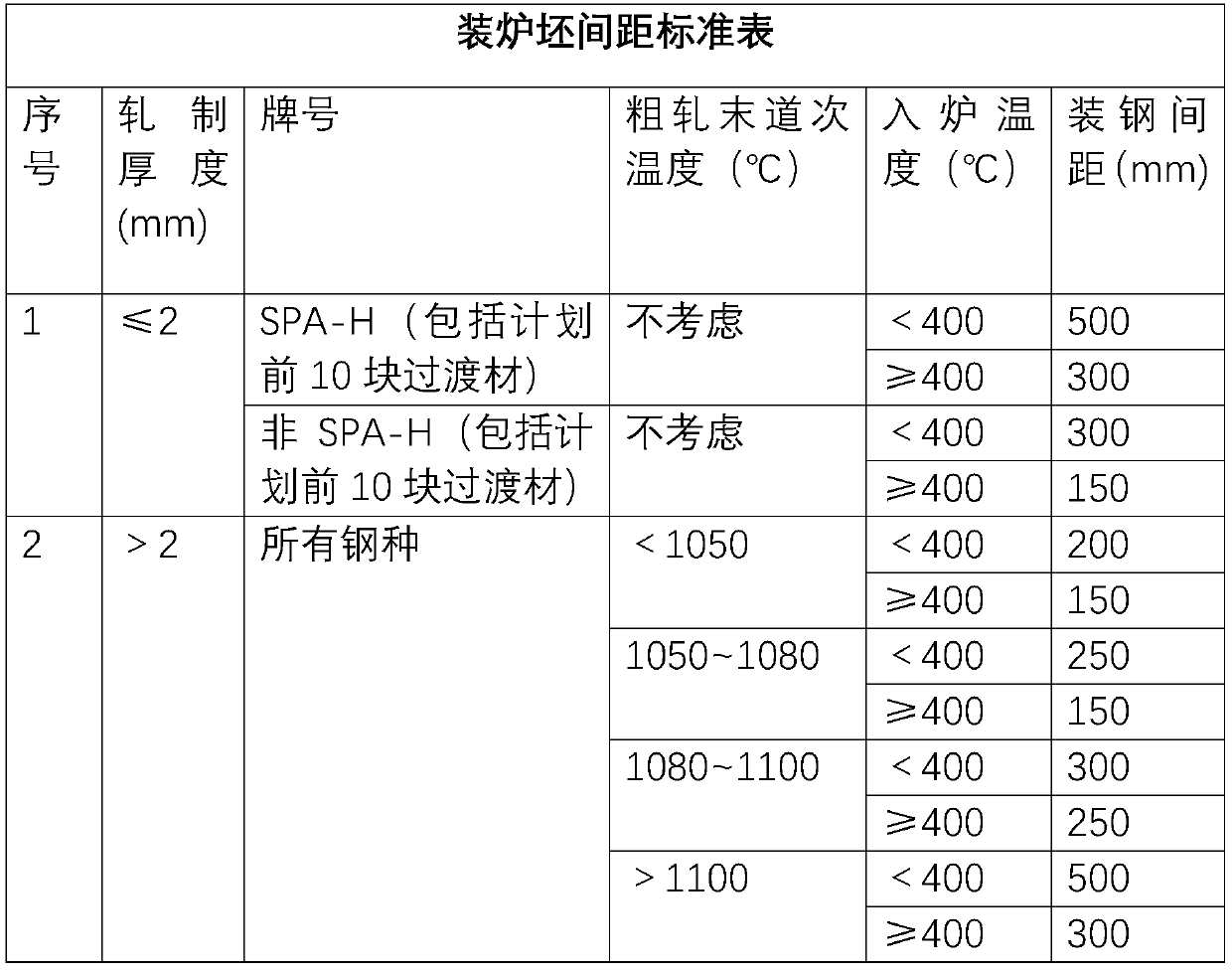

[0058] A method for determining the steel loading time and preventing hot-delivered steel billet from damaging the equipment in front of the furnace. The method first predicts the time when the first steel billet is released from the furnace, and then predicts the time required for the tail of the furnace to meet the steel loading space, and compares the transportation of the steel billet to the location The time required for the roller table and positioning, when the latter two are equal, the billet conveying and positioning instructions are issued, and finally the steel loading program is started to realize the purpose of loading the billet into the furnace immediately without stopping after the billet is positioned.

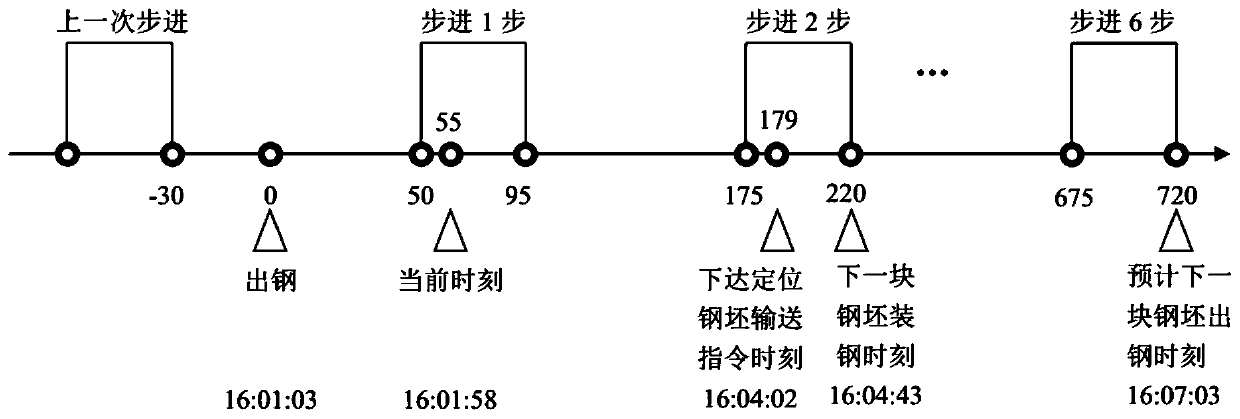

[0059] In this embodiment, a certain hot-rolling heating furnace is prepared to be loaded at a certain moment as an example, such as figure 1 and figure 2 As shown, the method for preventing the hot-delivery billet from damaging the furnace equipment specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com