Integrated stove and working control method thereof

A technology that integrates stoves and stove bodies, which is applied to household stoves, heating methods, and household stoves/stoves, etc., can solve the problems of low combustion efficiency of stoves, low thermal efficiency of stoves, and large amount of oil fume escape, and achieves improved temperature field distribution, The effect of improving the effect of absorbing oil fume and reducing the speed of dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

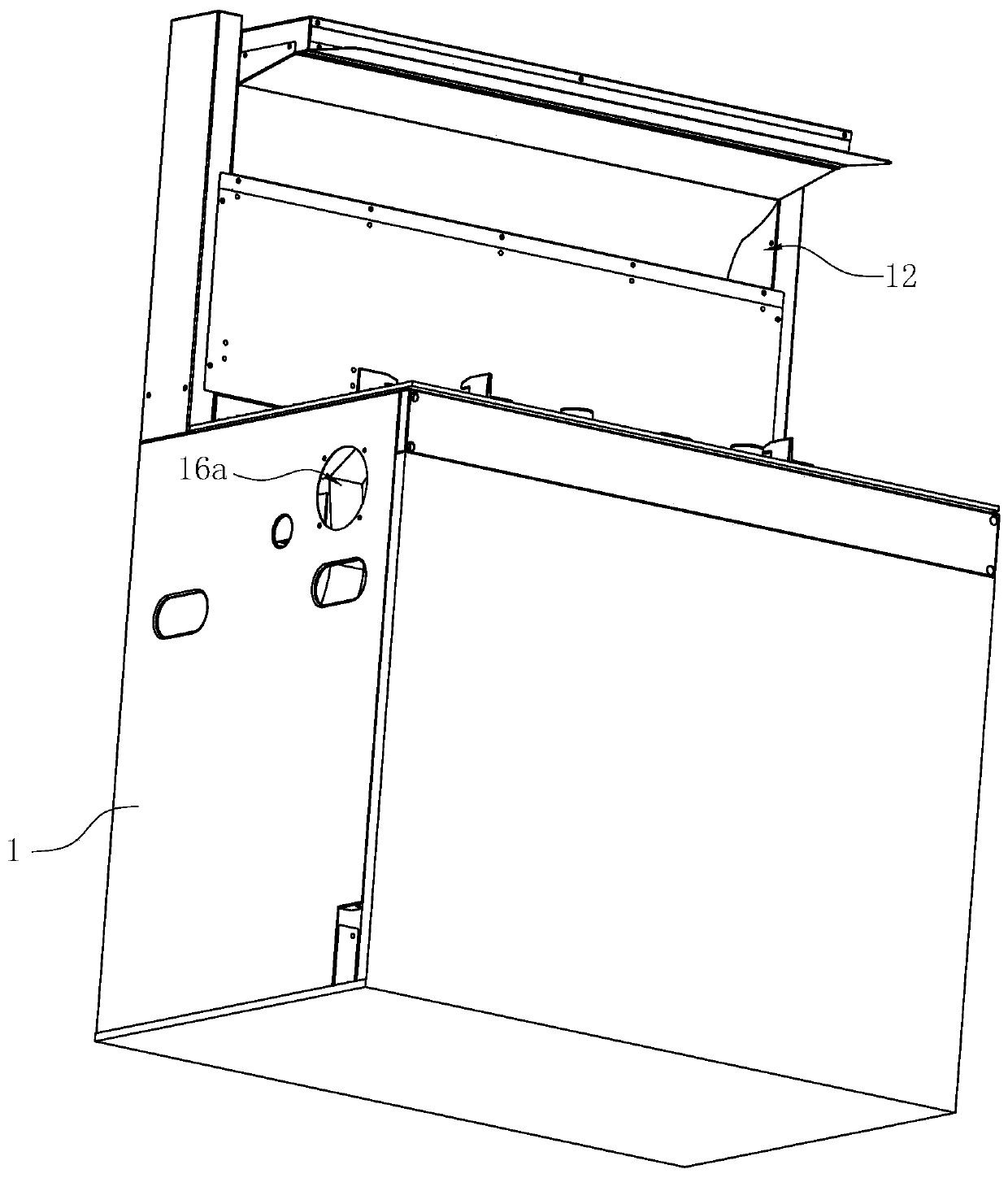

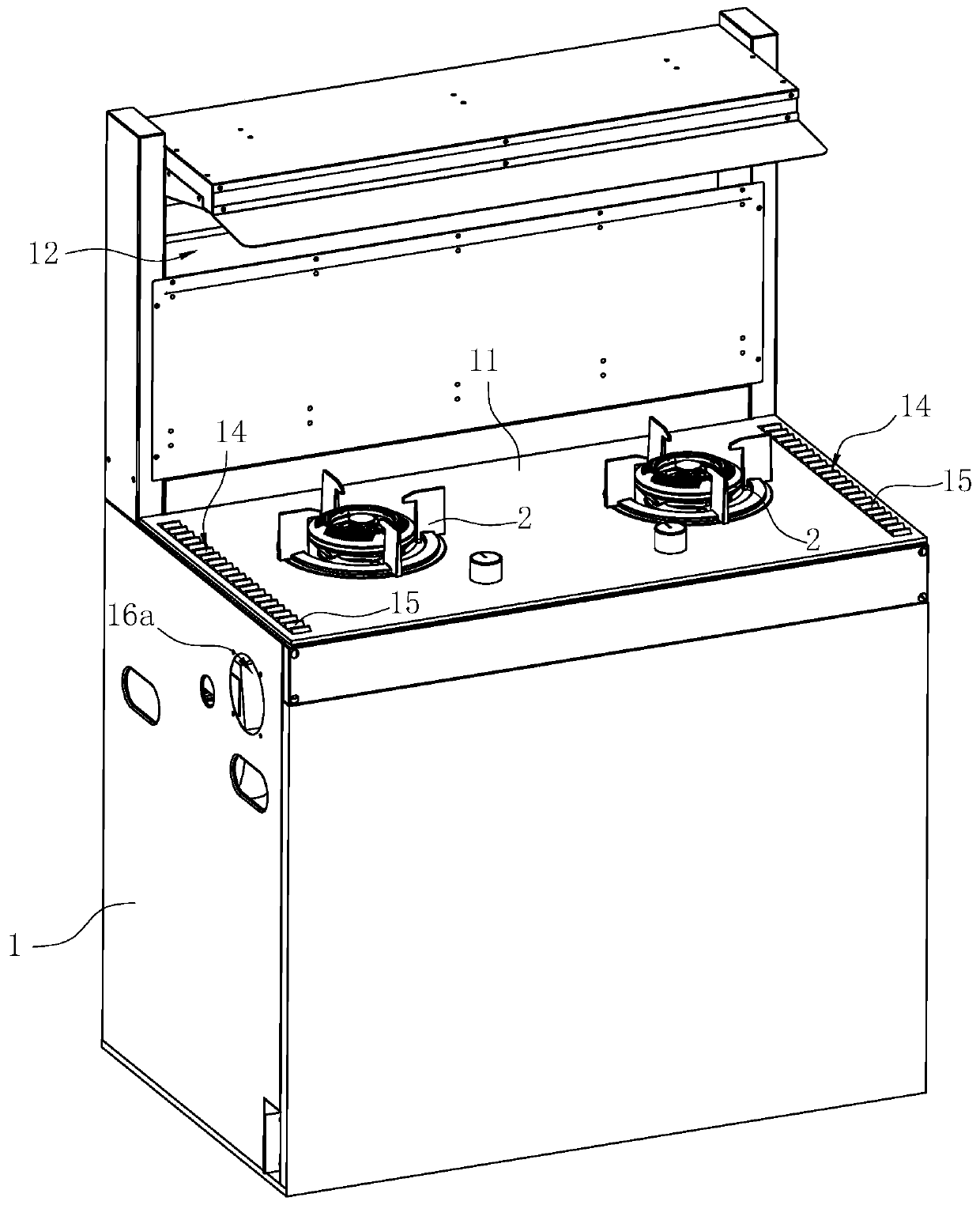

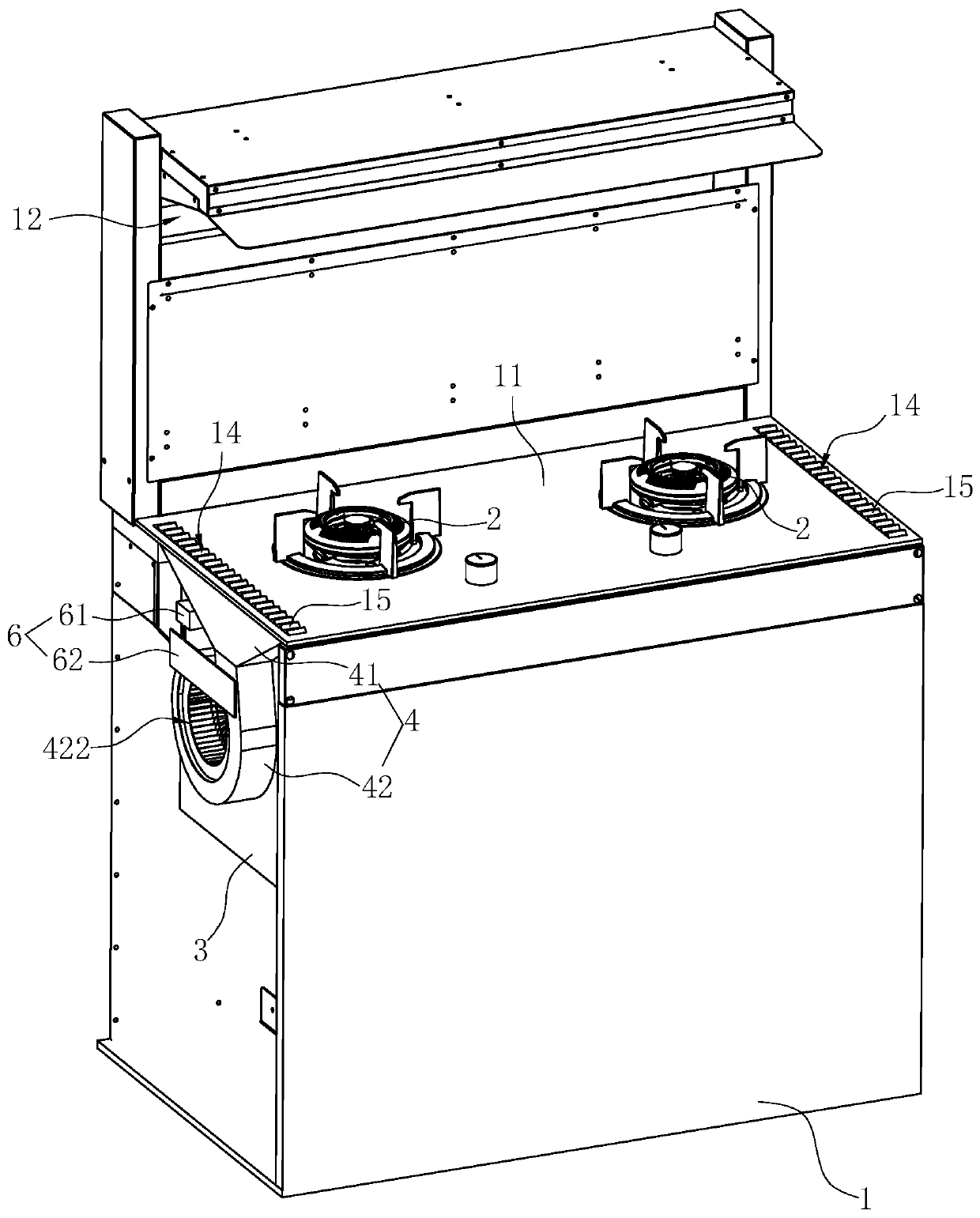

[0040] like Figure 1-11 As shown, it is a preferred embodiment of an integrated cooker and its working control method of the present invention. The integrated cooker includes a cabinet 1, a cooker 2 arranged on the table 11 of the cabinet 1, a cooker 2 arranged on the cabinet 1 The oven 3 and the cooling device 4 below the table top 11.

[0041]Wherein, the cabinet body 1 is provided with a fume suction port 12 and a fume discharge port 13, the fume suction port 12 is located at the upper rear of the stove body 2, and is distributed along the left and right direction of the stove body 2; the design of the fume discharge port 13 can refer to existing In the prior art, it is arranged at the bottom of the cabinet body 1 and is connected with a fan to discharge the oil fume entering from the oil fume suction port 12 through the oil fume discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com