Parameter verification device, system and method for special-shaped machined part

A special-shaped processing and parameter verification technology, applied in the direction of measuring devices, optical devices, manufacturing tools, etc., can solve the problems of measurement point evaluation, difficulty, and different forms and functions of terminal operating devices, so as to solve the problem of accuracy of measurement accuracy , The system precision is stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

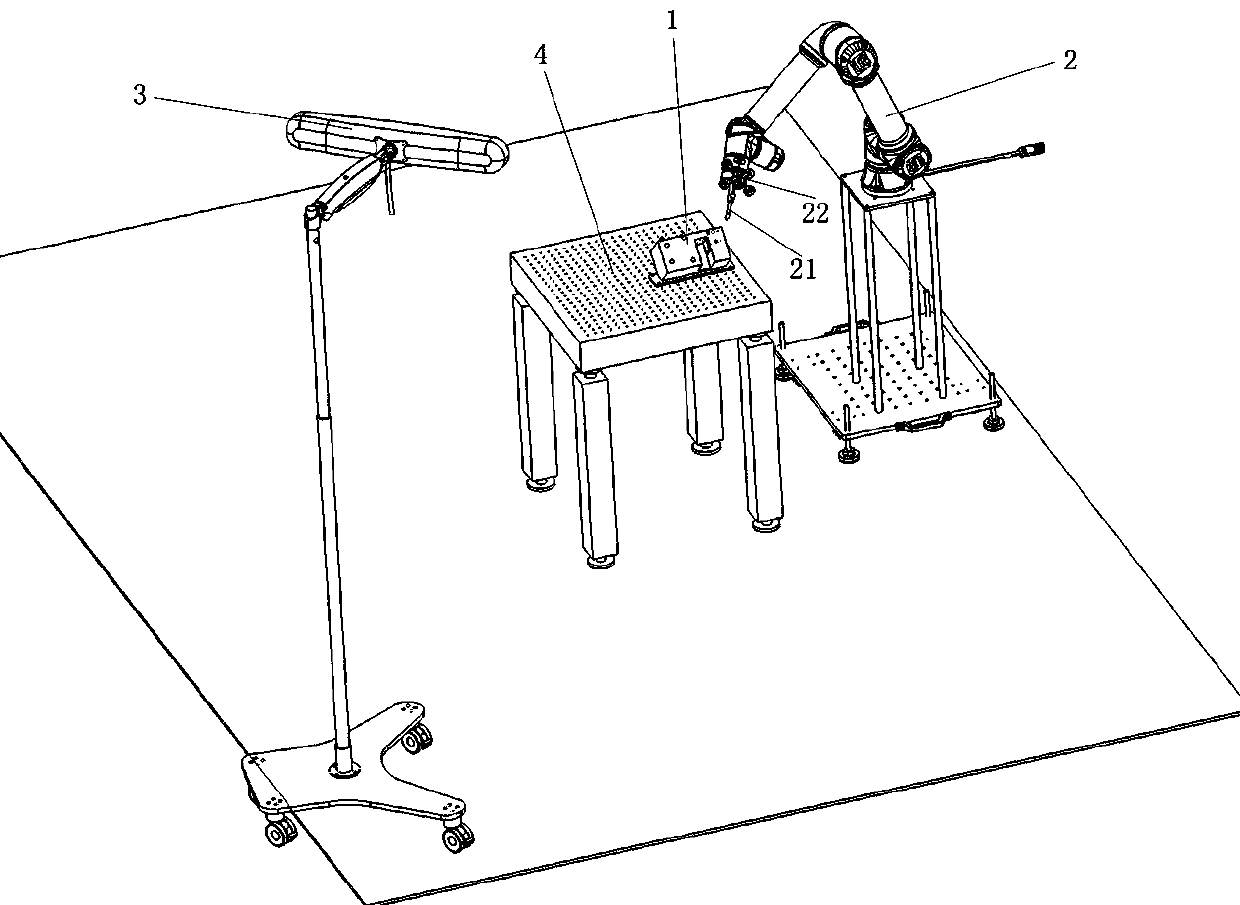

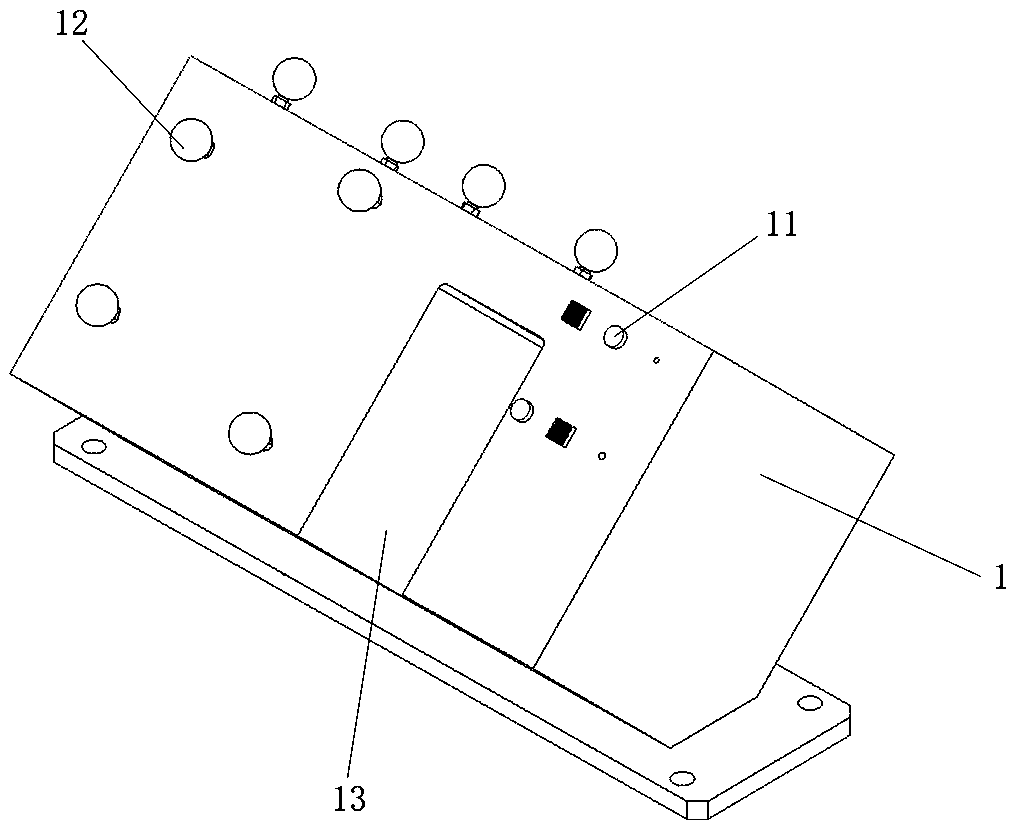

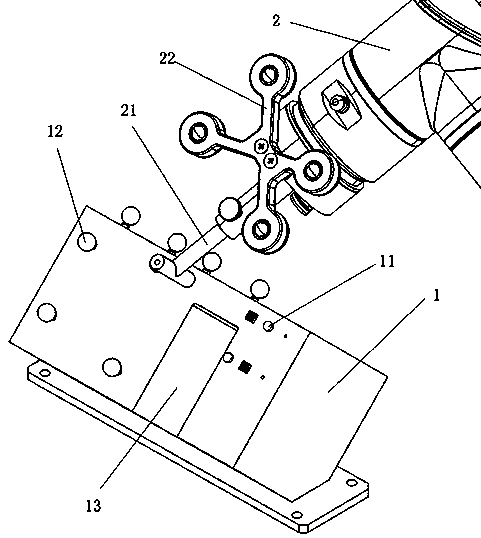

[0040] figure 1 It is a schematic diagram of the parameter verification system for special-shaped workpieces of the present invention. Such as figure 1 As shown, the special-shaped workpiece parameter verification system of the present invention includes an optical tracker 3, a parameter verification device 1, a mechanical arm 2 and a host computer; the parameter verification device 1 is placed on an optical platform 4, and the parameter verification device 1 has an inclined plane or Two symmetrical slopes, on which the first tracer 12 and at least one small hole 11 are installed, the first tracer 12 includes at least three coplanar non-collinear reflective balls that can be identified by the optical tracker . In the present invention, the first tracer 12 has 4 coplanar and non-collinear reflective balls, one of which is used to calibrate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com