Laser diode device

A technology of laser diodes and equipment, applied in lasers, laser devices, laser parts, etc., can solve the problems of disallowing components and heat removal, and achieve the effect of improving heat removal and simplifying process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

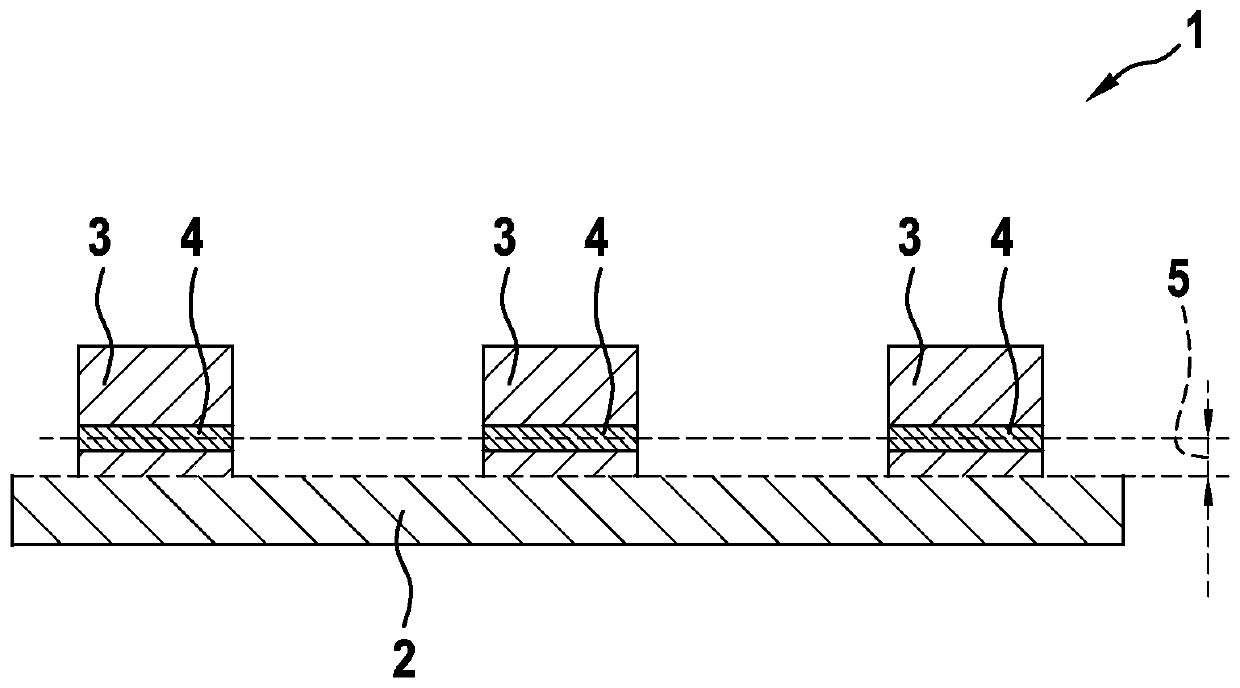

[0027] exist figure 1 A laser diode device 1 is shown in . The laser diode device 1 has a thermally conductive substrate 2 with a flat surface for dissipating heat from the surrounding environment. Substrate 2 can for example be made of AlN, Al 2 o 3 , Si or glass. A plurality of laser diodes 3 are arranged on the substrate 2 (three laser diodes 3 are shown here; however, more laser diodes 3 may also be provided, for example up to twenty). Each of the laser diodes 3 has one or more (active) epitaxial layers 4 . Epitaxial layer 4 is arranged on the side of laser diode 3 facing substrate 2 . The individual epitaxial layers 4 are placed passively above the planar substrate 2 in a plane-parallel manner with high precision at a substantially common height 5 .

[0028] The combination of the planarity of the substrate 2 and the small process fluctuations of the epitaxial layer 4 results in a very precise adjustment of the laser diode 3 perpendicular to the substrate 2 and perp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com