Intelligent Industrialized Microchannel Continuous Reactor

A microchannel and reactor technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve the problems of rare industrial microchannel reactors, restrictions on popularization and application, complex processing technology, etc. problems, to achieve the effect of reducing back-mixing and side reactions, reducing investment and operating costs, and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and example the present invention will be further described:

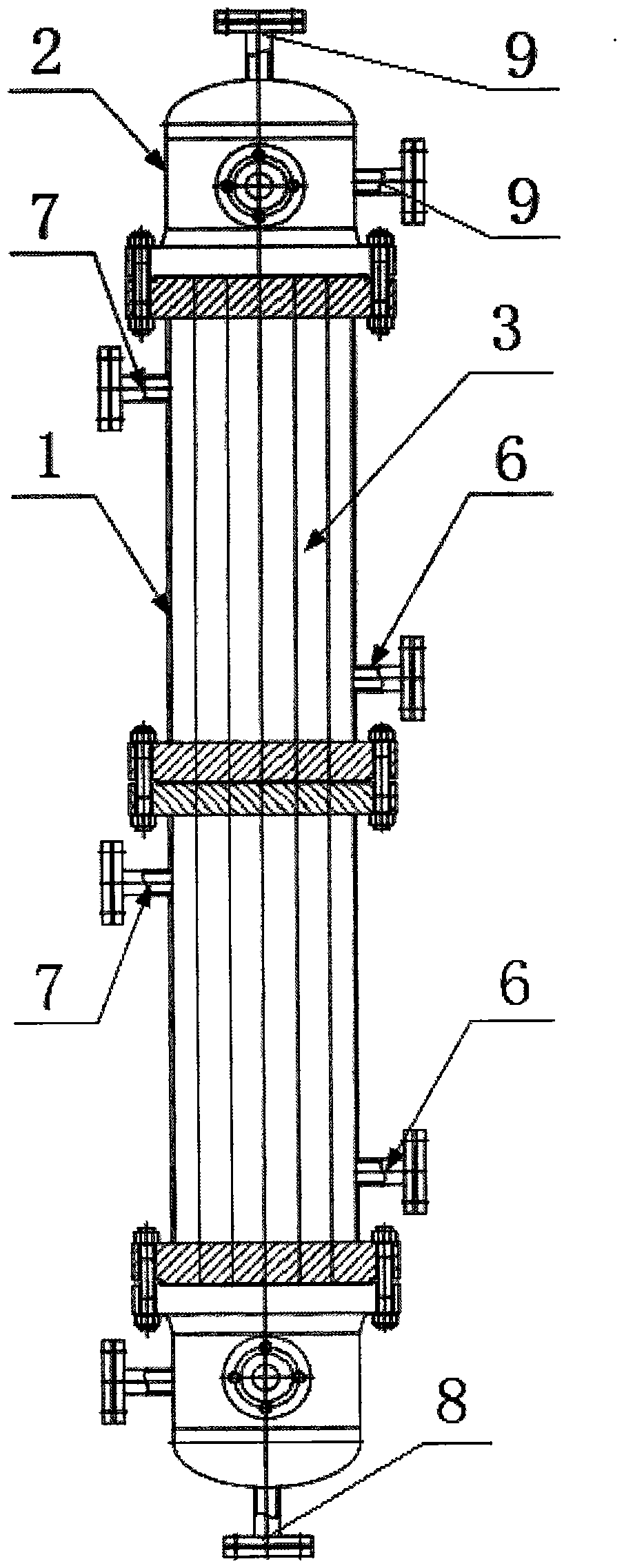

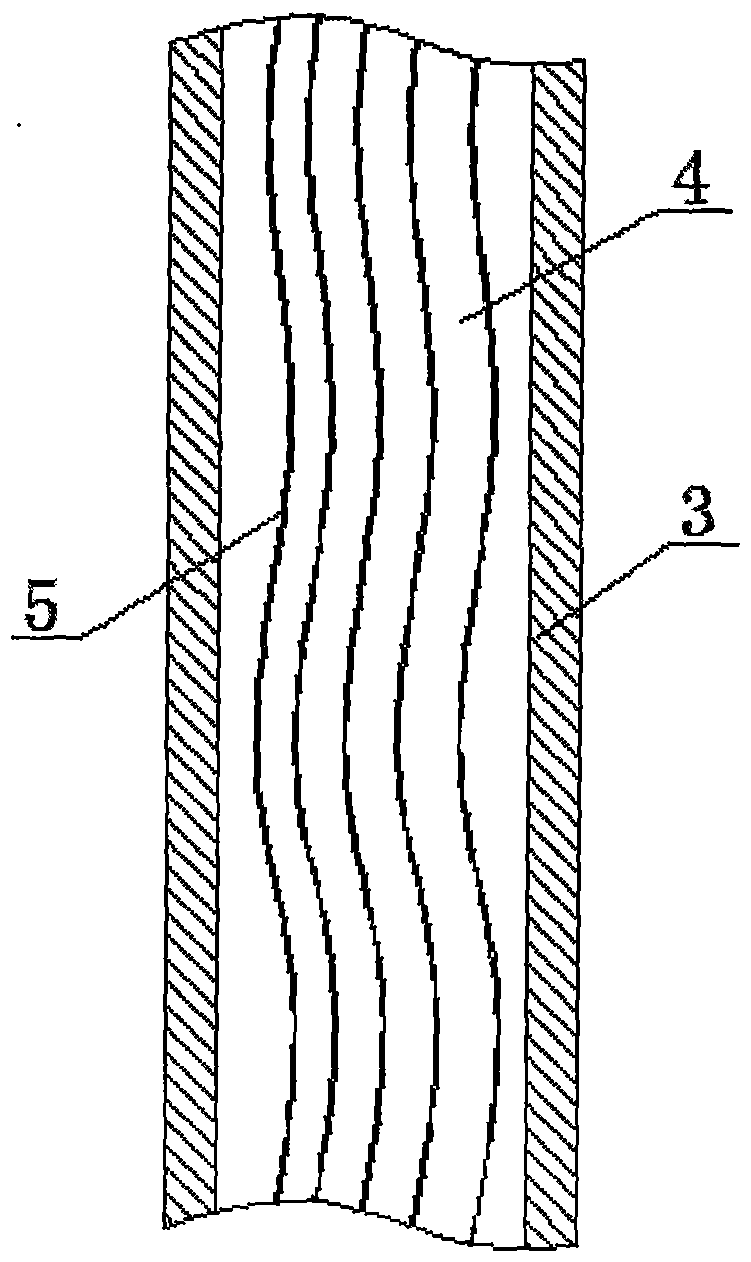

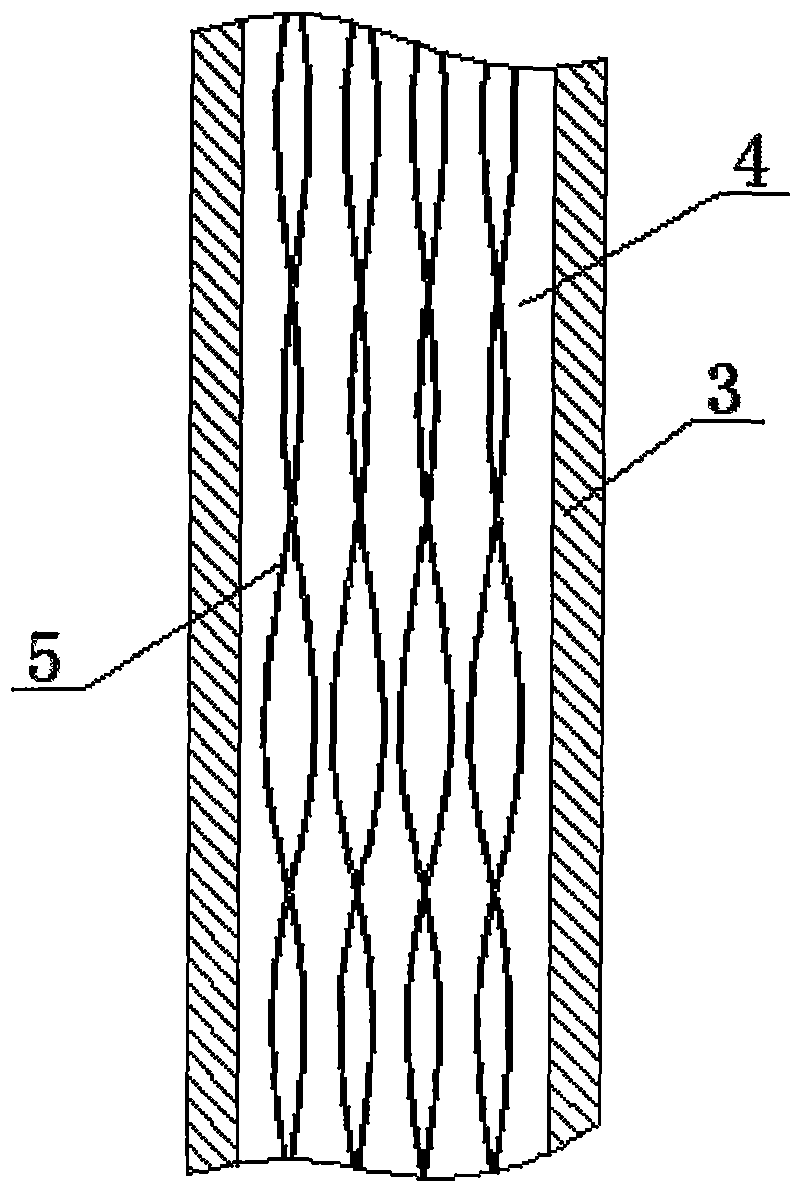

[0027] Such as figure 1 and figure 2The shown intelligent industrialized microchannel continuous reactor, the intelligent industrialized microchannel continuous reactor, includes: a shell 1 with a heat carrier inlet 6 and a heat carrier outlet 7, a raw material inlet 8, a product outlet 9, and the shell is blocked The end caps 2 at both ends and the reaction tube 3 for the reaction of the reaction material, the reaction tube is arranged in the shell, the inner cavity of the reaction tube 3 is the tube side, the gap between the shell 1 and the reaction tube 3 The cavity between them becomes the shell side, the raw material inlet 8 and the product outlet 9 communicate with the tube side, and the heat carrier inlet 6 and the heat carrier outlet 7 communicate with the shell side, and it is characterized in that: the reaction tube 3 is tightly inserted with a thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com