Electrode sheet for all-solid secondary batteries, all-solid secondary battery, and production methods for electrode sheet for all-solid secondary batteries and all-solid secondary battery

A secondary battery and manufacturing method technology, applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as liquid leakage, and achieve the effects of high discharge capacity density, peel strength and excellent flexibility of electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

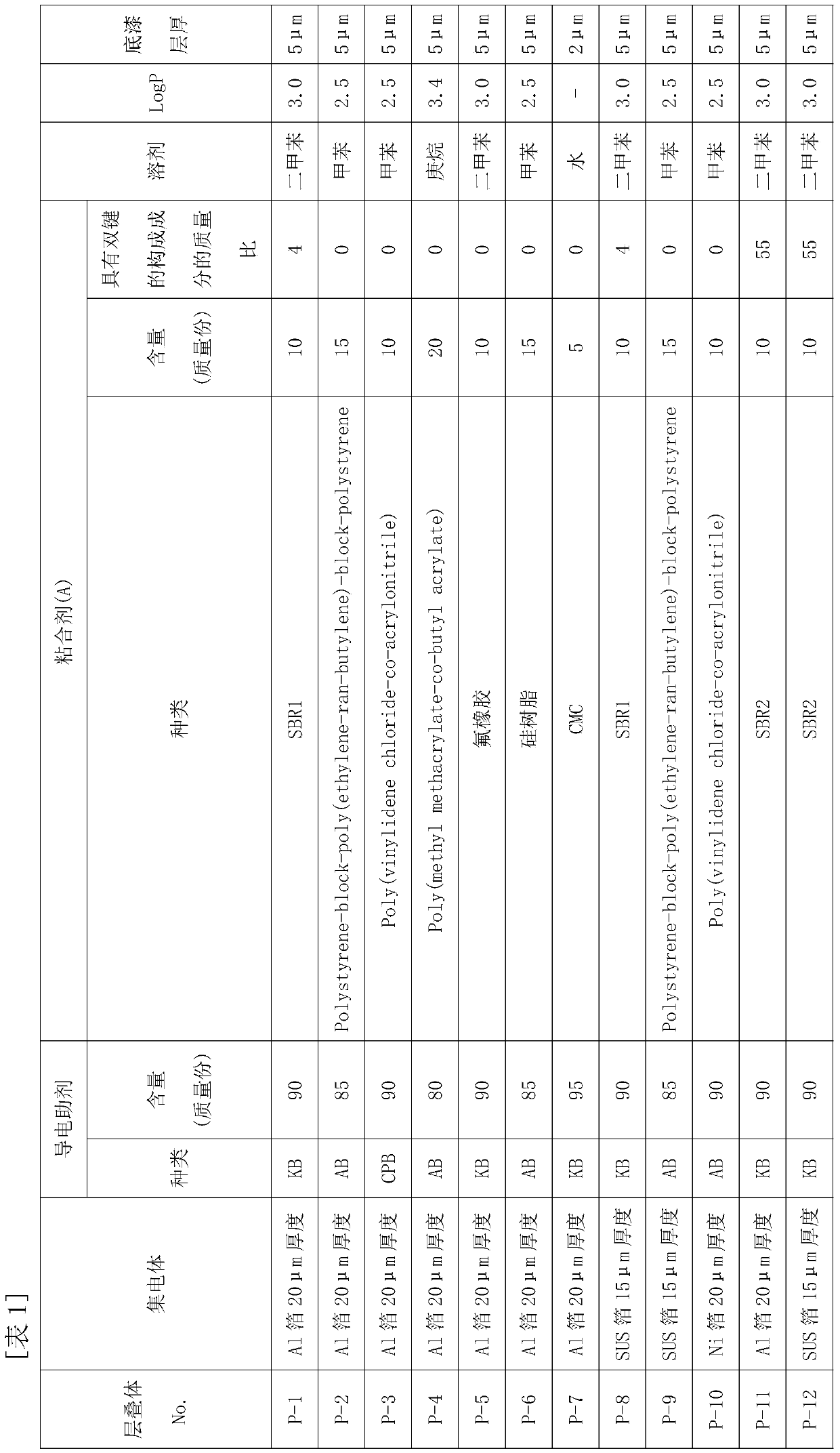

[0255] (Preparation of composition for primer layer formation)

[0256] The primer layer-forming composition is prepared by mixing the binder (A) and the conductive auxiliary agent in the presence of a solvent to slurry or make a solution.

[0257] Slurry can be performed by mixing a binder (A), a conductive additive, and a solvent using various mixers. It does not specifically limit as a mixing apparatus, For example, a ball mill, a bead mill, a planetary mixer, a paddle mixer, a roll mill, a kneader, and a disc mill are mentioned. The mixing conditions are not particularly limited. For example, when using a ball mill, mixing is preferably performed at 150 to 700 rpm (rotation per minute) for 1 to 24 hours. After mixing, it can be filtered if necessary.

[0258] The conductive auxiliary agent may be added and mixed simultaneously with the dispersion process of the binder (A), or may be added and mixed independently. In addition, when preparing a composition for forming a p...

Embodiment

[0310] Hereinafter, the present invention will be described in further detail based on examples. In addition, the present invention is not limited thereto and interpreted. In the following examples, "parts" and "%" showing the composition are based on mass unless otherwise specified. Also, "room temperature" means 25°C.

[0311]

[0312] (Synthesis of Poly(methyl methacrylate-co-butyl acrylate))

[0313]In a 1000 mL three-necked flask equipped with a reflux cooler and a gas introduction plug, 24.0 g of methyl methacrylate (manufactured by Wako Pure Chemical Industries, Ltd.), 96.0 g of butyl acrylate (manufactured by Wako Pure Chemical Industries, Ltd.) and 480.0 g of toluene, after carrying out 2 nitrogen replacements, as an initiator, add 2.4 g of V-65 (trade name) manufactured by Wako Pure Chemical Industries, Ltd., further after carrying out 2 nitrogen replacements, under nitrogen flow and in It was heated at 70°C for 3 hours. Heating was continued until the disappea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com