Preparation method of water-baked salt-baked chicken product

A technology for baking salt and chicken in water is applied in the directions of food ingredients, food ultrasonic treatment, food ingredients as odor modifiers, etc. It can improve the type and content of flavor substances, improve the tenderness and texture characteristics of chicken, and be suitable for large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

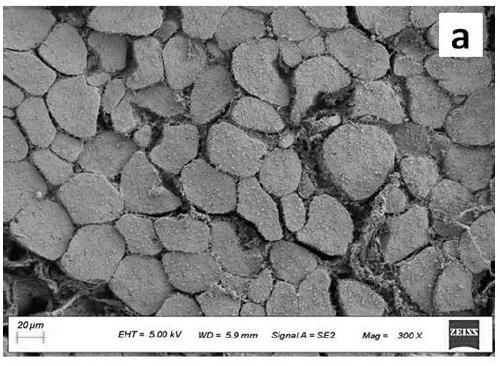

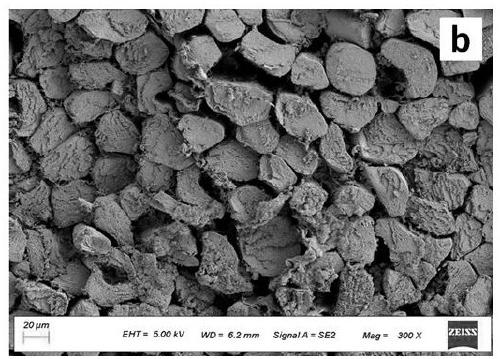

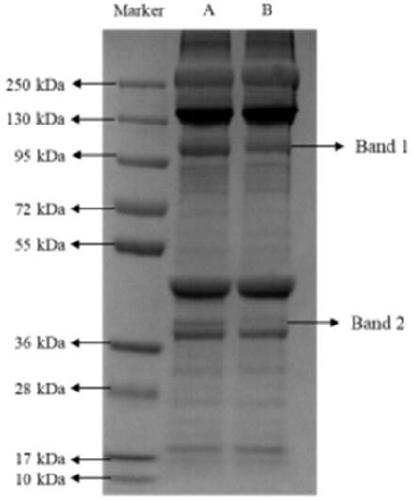

Image

Examples

Embodiment 1

[0033] Embodiment 1: Traditional water-baked salt-baked chicken processing method;

[0034]1. Trim and weigh the thawed chicken at 4°C, prepare the pickling liquid according to the weight of the chicken, the ratio of liquid to meat is 1:1, and the amount of sodium chloride added is 10%, and the added amount is calculated by the weight of the meat (that is, chlorine Sodium is 10% by weight of chicken).

[0035] 2. In the step 1, the ingredients of the pickling solution are: 0.05% of pepper juice, 0.08% of five-spice juice, 0.04% of ethyl maltol, 0.15% of sodium glutamate, 0.2% of sand ginger powder (that is, the pepper juice is 0.05% of the chicken weight %, spiced juice is 0.08% of chicken weight, ethyl maltol is 0.04% of chicken weight, sodium glutamate is 0.15% of chicken weight, sand ginger powder is 0.2% of chicken weight).

[0036] 3. Conditions for pickling in still water: temperature 4°C, pickling time 15 hours.

[0037] 4. Take out the marinated chicken, blanch until...

Embodiment 2

[0041] Embodiment 2: A water-baked salt-baked chicken product of the present invention and a preparation method thereof.

[0042] 1. Trim the thawed chicken at 4°C and weigh it. Prepare the marinade according to the weight of the chicken. The ratio of liquid to meat is 1:1. . Use intermittent tumbling, tumbling for 20 minutes, and rest for 10 minutes. The vacuum tumbling time was 10 hours respectively. Finish the chicken with a tumble marinade.

[0043] 2. The ingredients of the pickling solution described in step 1 are (by chicken weight): the addition of sodium chloride is 6%, and the addition of sodium tripolyphosphate is 0.35%; Zanthoxylum bungeanum juice 0.05%, five-spice juice 0.08%, B Base maltol 0.04%, sodium glutamate 0.15%, sand ginger powder 0.2%. (That is, the addition of sodium chloride is 6% of the weight of the chicken, the addition of sodium tripolyphosphate is 0.35% of the weight of the chicken; the pepper juice is 0.05% of the weight of the chicken, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com