Torsion damper and power transmission device

A technology of power transmission and torsional shock absorber, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., and can solve problems such as transmission belt and transmission pin slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

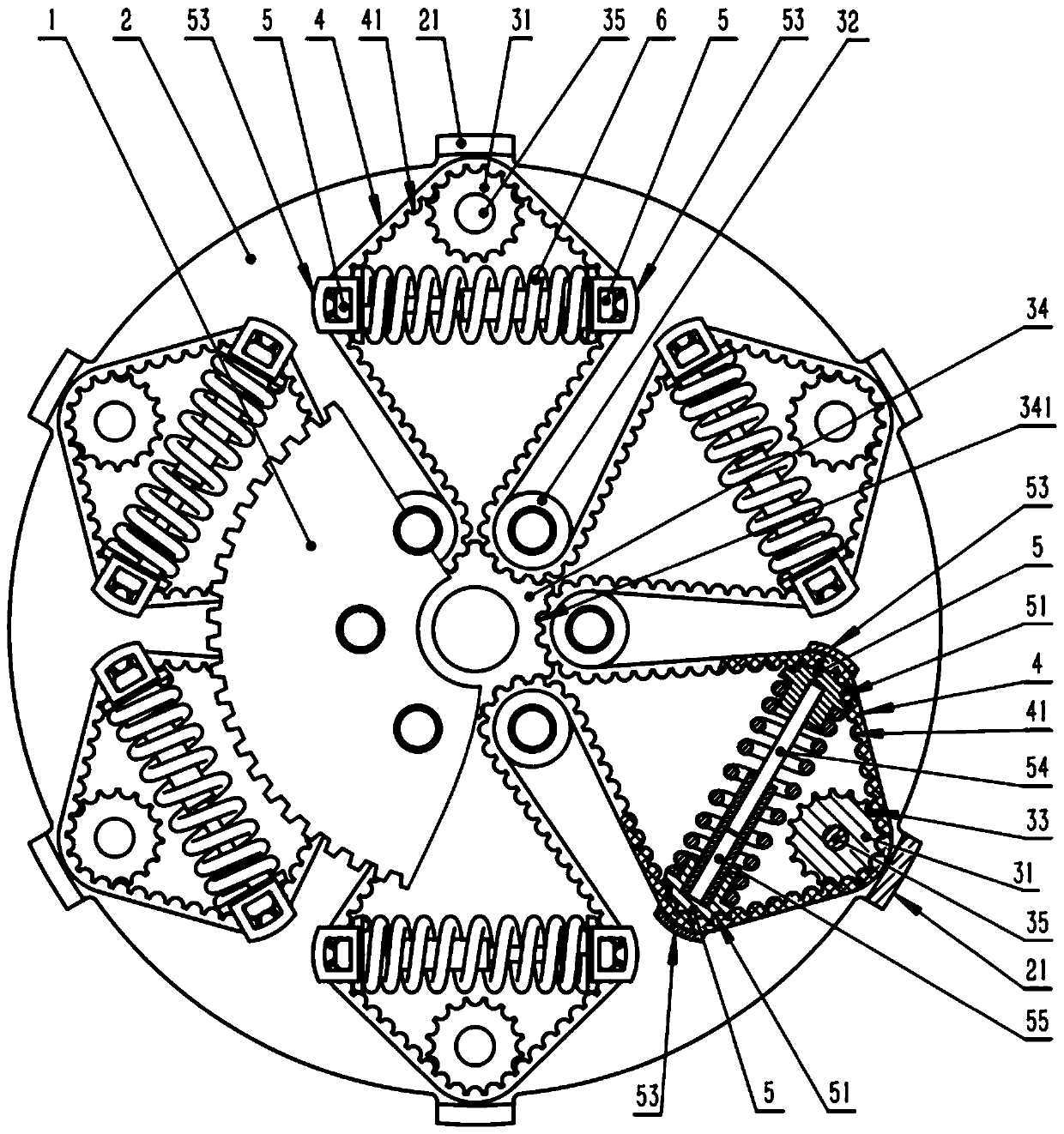

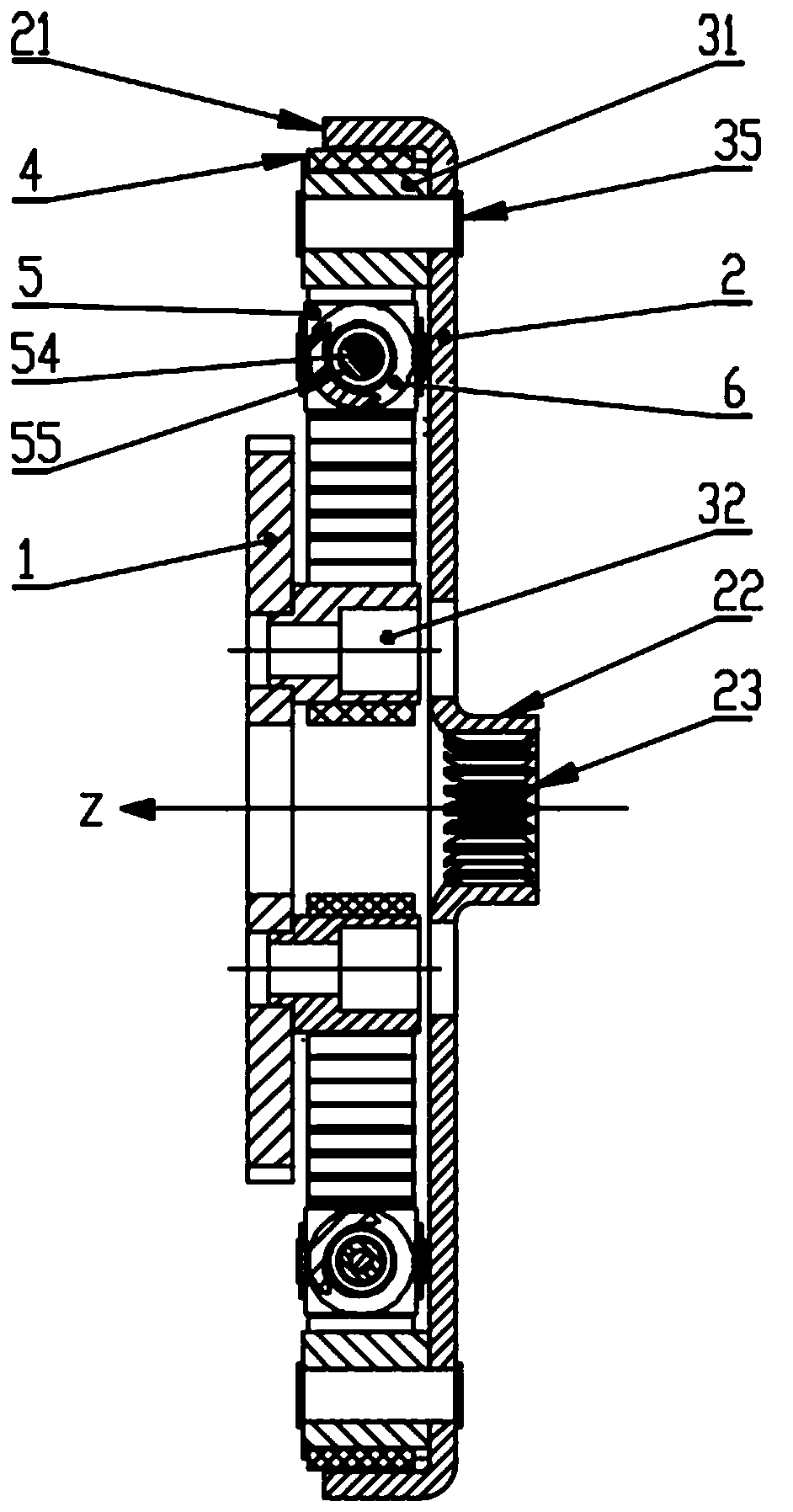

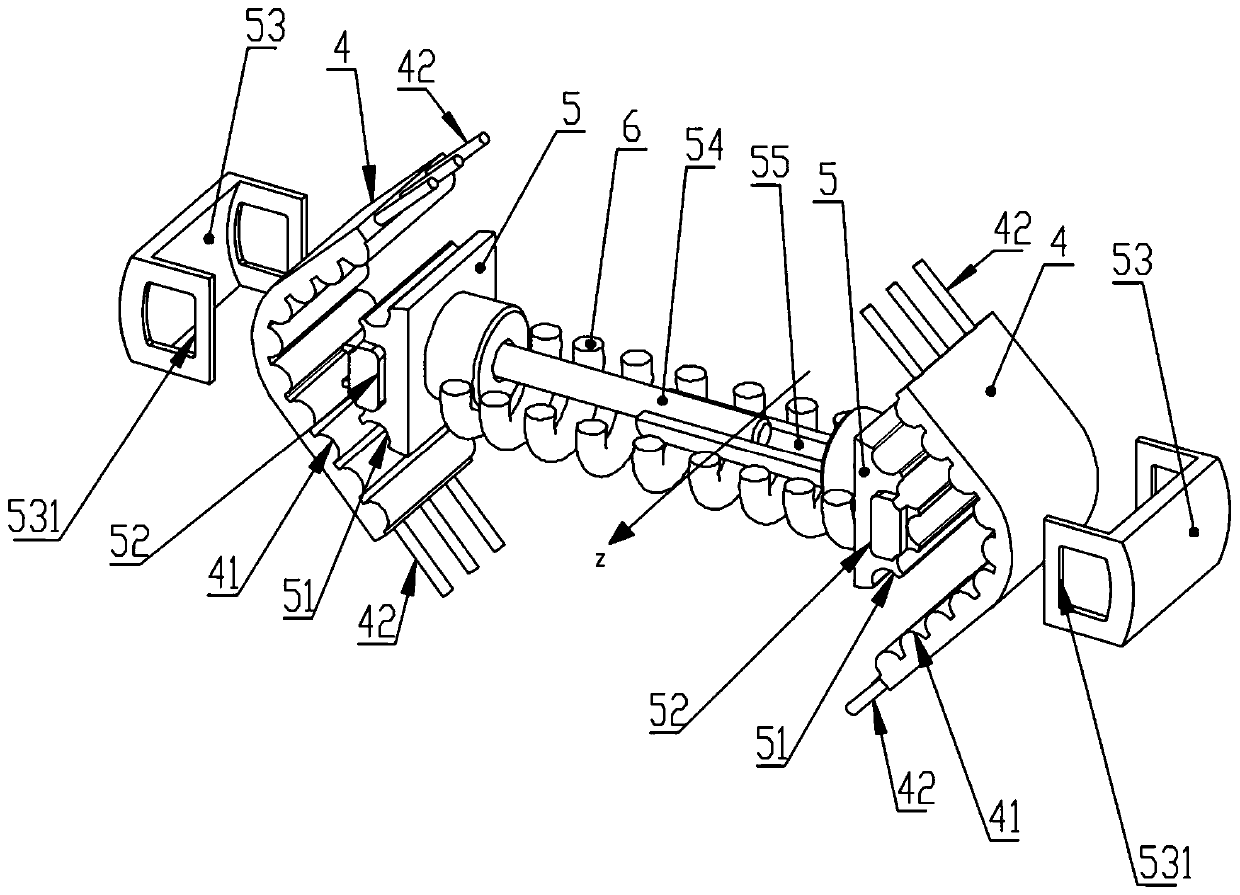

[0044] Such as Figure 1 to Figure 6 As shown, the present invention provides a torsional vibration absorber and a power transmission device, and the power transmission device includes a first flywheel 1, a second flywheel 2 and a torsional vibration damper. Wherein the first flywheel 1 and the second flywheel 2 are coaxially arranged along the Z axis, and in this embodiment, the first flywheel 1 is located above the second flywheel 2 . The torsional damper includes an outer drive pin 31, an inner drive pin 32, a drive belt 4 and a spring seat 5, the number of the outer drive pins 31 and the inner drive pins 32 are the same, and the outer drive pins 31 are arranged at the edge of the second flywheel 2 at equiangular intervals, and the inner drive pins 32 are arranged at the center of the first flywheel 1 at equal angular intervals, that is, the outer transmission pin 31 is arranged on the outer periphery of the inner transmission pin 32 . The transmission belt 4 has a closed ...

Embodiment 2

[0062] see Figure 7 , the present invention provides another kind of power transmission device, the difference from Embodiment 1 is that the outer transmission pin 31 is arranged on the first flywheel 1 as the power input end, and the inner transmission pin 32 is arranged on the second flywheel 2 as the power output end , and the center of the second flywheel 2 is provided with a stop claw 34, and the inner peripheral surface of the stop claw 34 is provided with a spline 23. At this moment, the spline 23 and the stop claw 34 are provided as an integral structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com