Drying device for corrugated board processing

A drying device and corrugated cardboard technology, which is applied in the field of corrugated cardboard processing, can solve the problems of large drying differences of corrugated cardboard, easy slipping of corrugated cardboard movement, and uneven temperature distribution, so as to reduce drying differences and ensure good health , the effect of reducing the temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

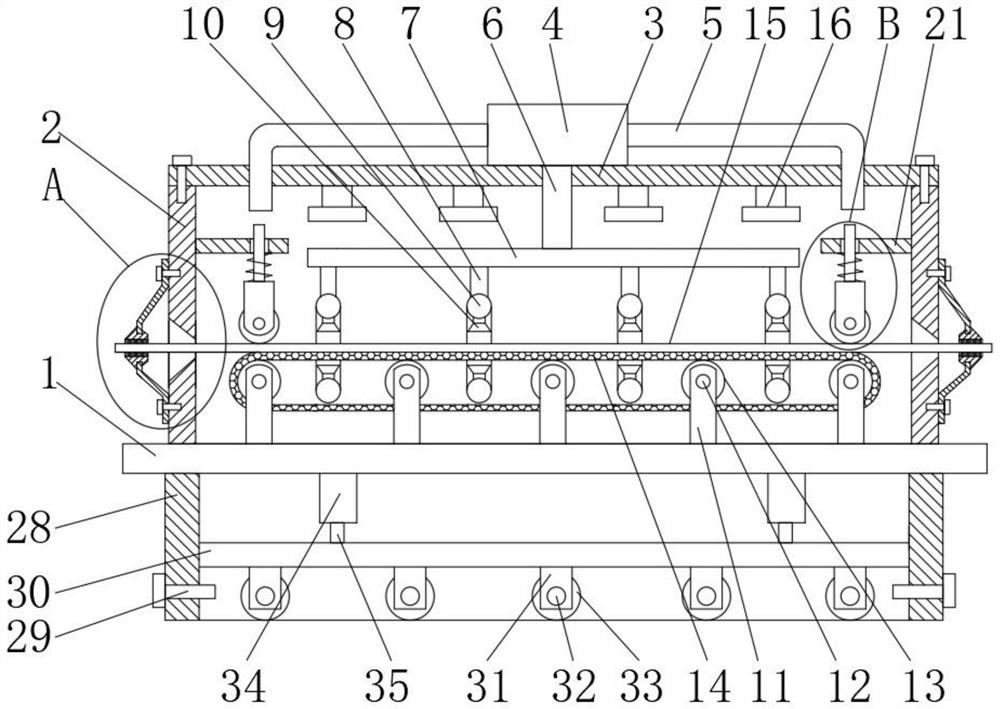

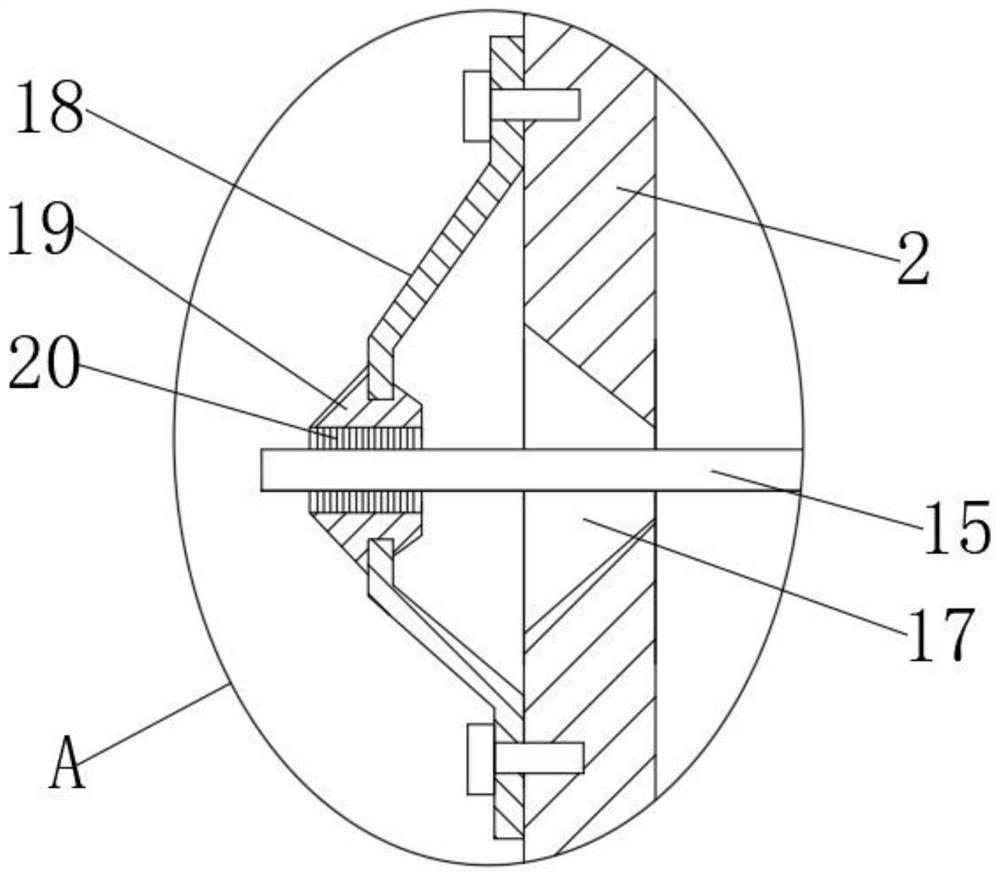

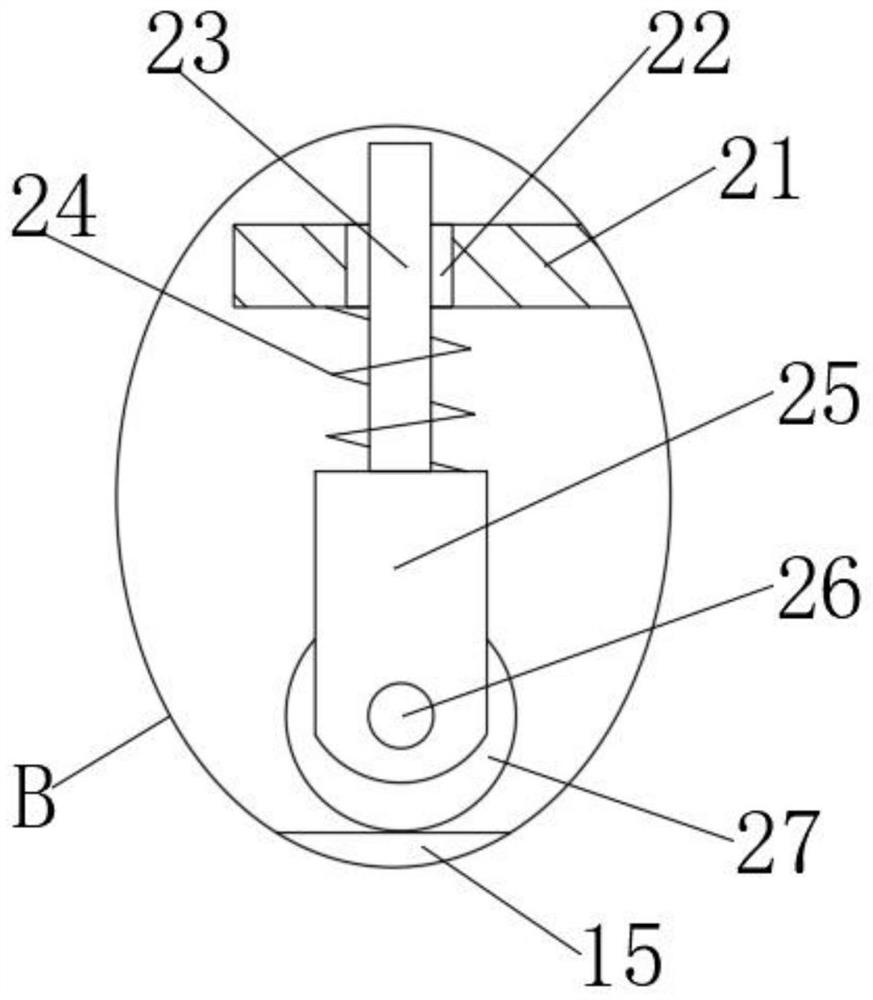

[0049] see Figure 1-6 , a drying device for corrugated cardboard processing, including a support table 1;

[0050] The upper end of the supporting platform 1 is fixedly connected with several groups of shaft frames, and several groups of shaft frames are arranged at intervals along the front and back of the supporting table 1. The shaft frames include two oppositely arranged shaft frames 11, and any group of shaft frames in the several groups of shaft frames The same driving shaft 55 is rotatably connected to the two shaft frames 1 of the group, and the driving roller 56 is connected to the driving shaft 55 in linkage. The connecting shaft 12, the connecting shaft 12 is rotatably sleeved and connected with the driven roller 13, the driving roller 56 and several driven rollers 13 are jointly sleeved with the same conveyor belt 14, and the conveyor belt 14 is provided with several A through hole 57, the support table 1 is also provided with a conveyor belt driving device for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com