Cable laying equipment for electric power engineering and implementation method thereof

A cable laying and power engineering technology, applied in the direction of cable laying equipment, etc., can solve the problems of severe friction on the shaft seat, damage to the shaft seat, and inconsistent heights at both ends of the cable winch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

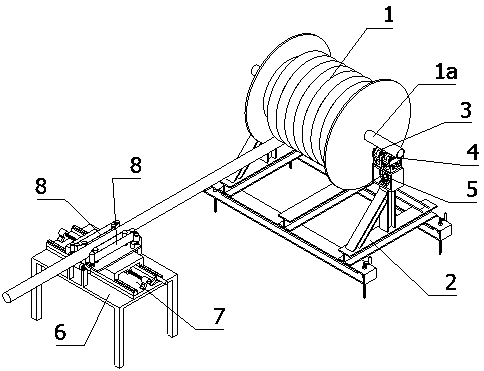

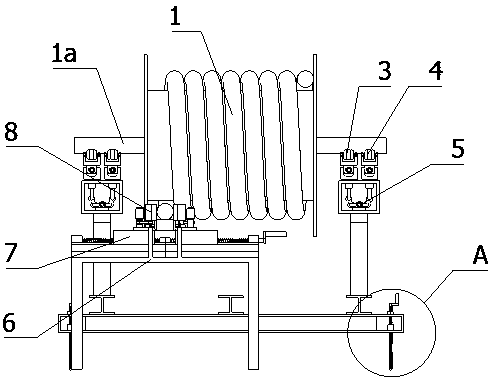

[0069] A method for implementing cable laying equipment for electric power engineering, comprising the following steps:

[0070] Step 1. The staff places the cable winch 1 on the adjustable support 2, and makes both ends of the winch shaft 1a mounted on the first shaft seat 3 and the second shaft seat 4;

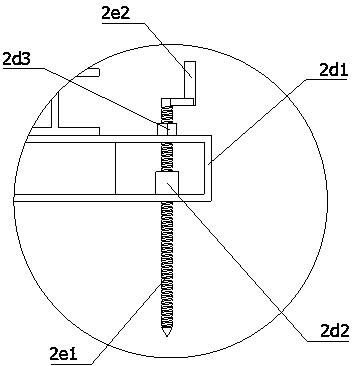

[0071] Step 2, the staff shakes the first handle 2e2 to change the relative position of the threaded rod 2e1 and the foundation support 2d, and finally makes the adjustable bracket 2 basically maintain a horizontal posture;

[0072] Step 3, the staff tear off one end of the cable from the cable winch 1, and place it on the third roller 6b and the fourth roller 6c;

[0073] Step 4, the staff shakes the second rocking handle 7f so that the working surfaces of the two belt conveyors 8 clamp the cable in the middle;

[0074] Step 5, the staff starts the belt conveyor 8, and the two belt conveyors 8 drive the cables to move towards the destination;

[0075] Step 6. When the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com