Winding structure of four-path parallel flat wire motor

A technology of motor winding and parallel connection, which is applied in the field of four-way parallel flat wire motor winding structure, can solve the problems of poor design flexibility, ineffective improvement of motor heat dissipation capacity, obvious conductor skin effect, etc., to meet the requirements of motor performance and The effect of temperature rise requirements, reduction of conductor high-speed skin effect, and widening of selection space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

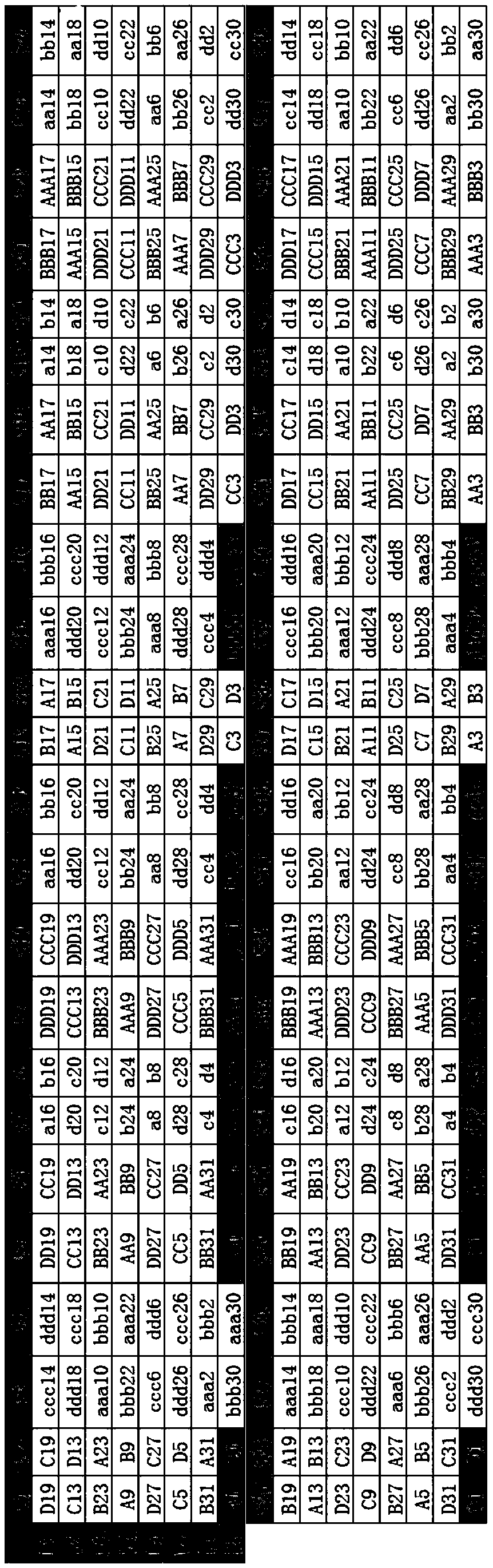

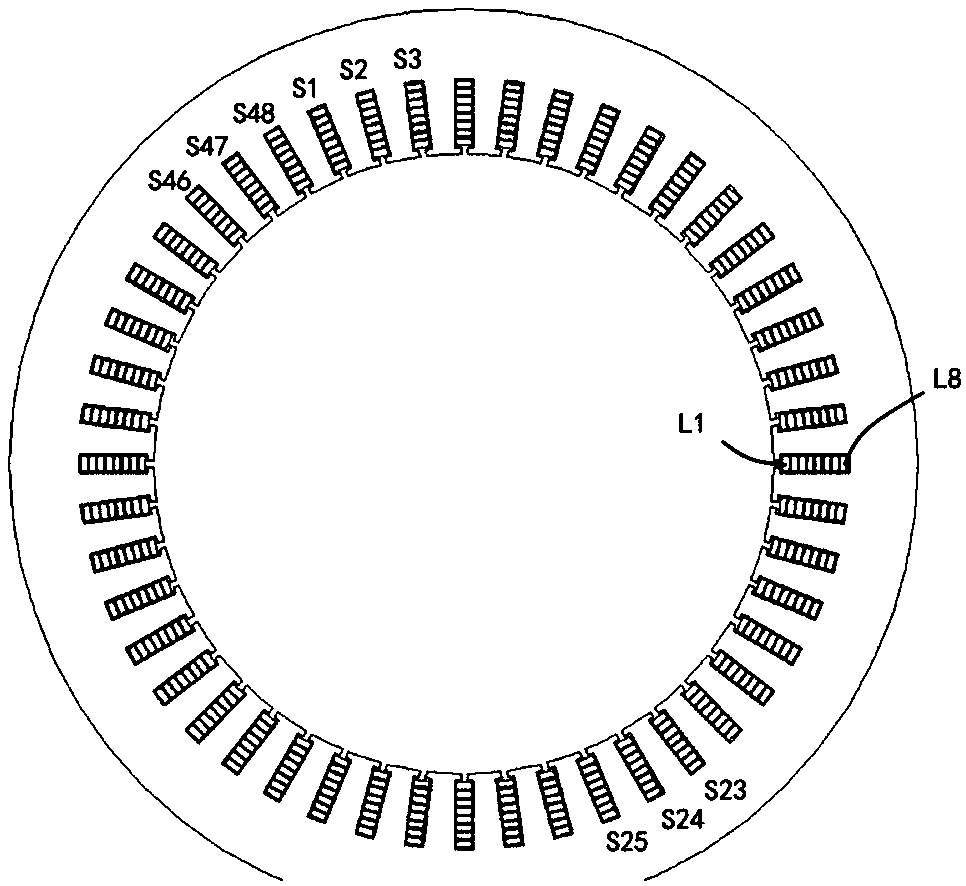

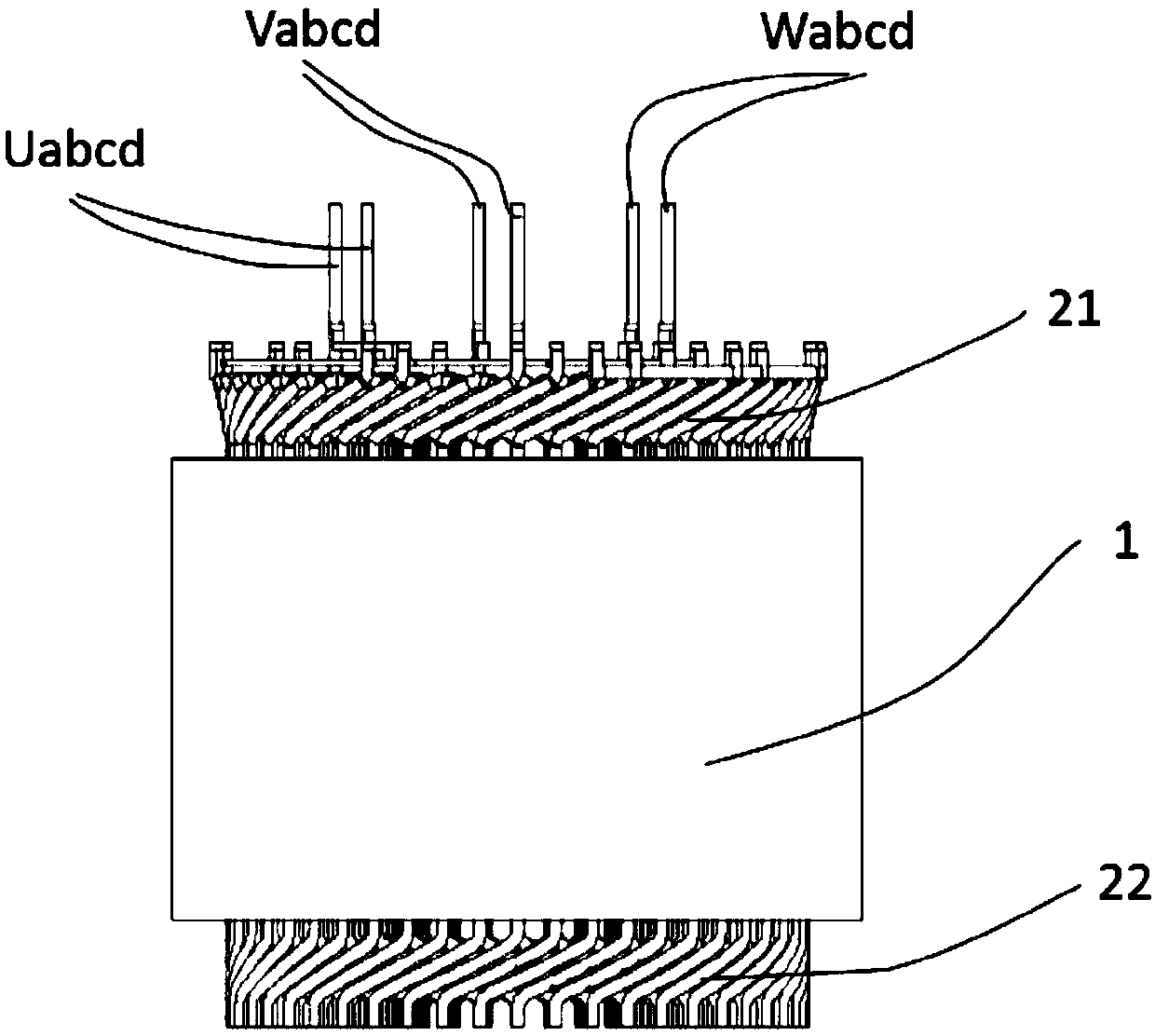

[0029] as attached Figure 1-6 As shown, a four-way parallel flat wire motor winding structure includes a stator core, and wire slots are opened on the teeth of the stator core. The flat copper wires are embedded in the corresponding slots according to the distribution method of the three-phase windings, and 48 slots are set on the inner ring of the stator core. figure 1 It is the winding connection diagram of the three-phase winding of the motor stator. Among them, S1, S2...S47, S48 represent the stator core slot number.

[0030] Each wire slot includes wire layers of 8 flat wires, and the flat copper wires are stacked and embedded sequentially along the radial direction of the stator core to form windings, and the wire layers are sorted in ascending order along the direction away from the center of the circle. Such as figure 1 As shown, L1, L2...L7, L8 represent the number of layers in each wire slot, and the wire layers are sequentially away from the center of the circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com