Hospital waste gas treatment device and method

A waste gas treatment device and hospital technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of transmission, insufficient sterilization and disinfection, and the spread of infectious diseases, so as to facilitate installation and layout and reduce the risk of disease infection , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

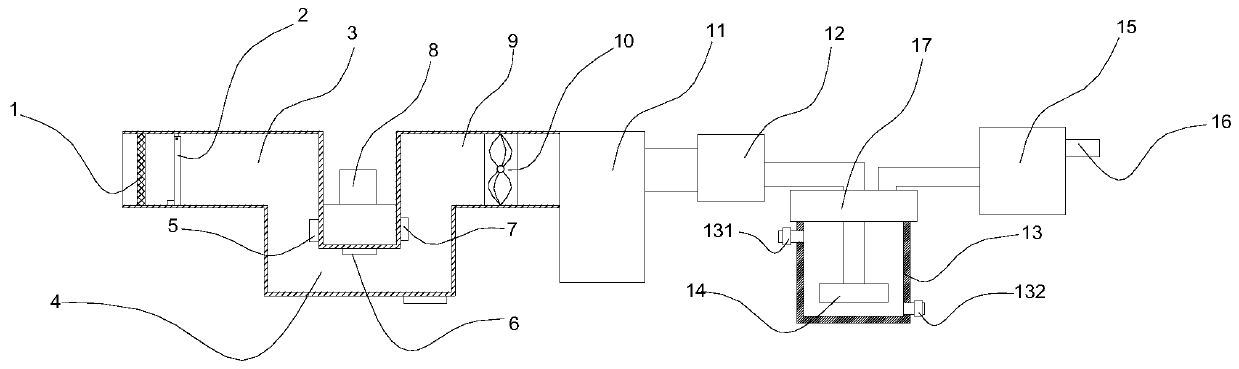

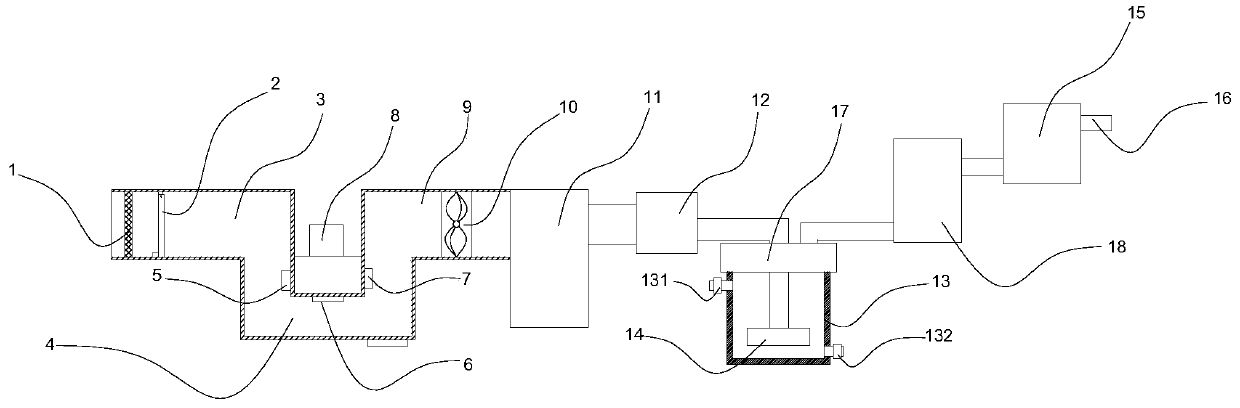

[0048] 1. Install suction pipes 3 in each department and treatment room of the hospital;

[0049] 2. The waste gas in the hospital is sucked into the U-shaped ultraviolet sterilizing pipe 4 through the suction pipe 3, and the air volume of the exhaust fan 10 is adjusted so that the air volume in the suction pipe 3 is 5m 3 / min;

[0050] 3. Then, in the U-shaped ultraviolet sterilizing tube 4, the wavelength of the ultraviolet lamp is controlled by the ultraviolet lamp controller 8 to be 250nm; to realize the ultraviolet disinfection of the exhaust gas;

[0051] 4. The waste gas after ultraviolet disinfection is filtered through the first filter 11; then the wind pressure is 30pa by adjusting the booster fan 12; so that the waste gas after the first filtration enters the disinfection pool 13;

[0052] 5. Adding the 84 disinfectant solution with an available chlorine concentration of 1000 mg per liter in the disinfection pool 13; carrying out disinfection and sterilization of t...

Embodiment 2

[0055] 1. Install suction pipes 3 in each department and treatment room of the hospital;

[0056] 2. The waste gas in the hospital is sucked into the U-shaped ultraviolet sterilizing pipe 4 through the suction pipe 3, and the air volume of the exhaust fan 10 is adjusted so that the air volume in the suction pipe 3 is 10m 3 / min;

[0057]3. Then, in the U-shaped ultraviolet sterilizing tube 4, the wavelength of the ultraviolet lamp is controlled by the ultraviolet lamp controller 8 to be 260nm; to realize the ultraviolet disinfection of the exhaust gas;

[0058] 4. The exhaust gas after ultraviolet disinfection is filtered through the first filter 11; then the wind pressure is 50pa by adjusting the booster fan 12; so that the exhaust gas after the first filtration enters the disinfection pool 13;

[0059] 5. Add 84 disinfectant with an available chlorine concentration of 1000 mg per liter to the disinfection pool 13; sterilize the waste gas through 84 disinfectant;

[0060] 6...

Embodiment 3

[0062] 1. Install suction pipes 3 in each department and treatment room of the hospital;

[0063] 2. The waste gas in the hospital is sucked into the U-shaped ultraviolet sterilizing pipe 4 through the suction pipe 3, and the air volume of the exhaust fan 10 is adjusted so that the air volume in the suction pipe 3 is 15m 3 / min;

[0064] 3. Then, in the U-shaped ultraviolet sterilizing tube 4, the wavelength of the ultraviolet lamp is controlled by the ultraviolet lamp controller 8 to be 270nm; to realize the ultraviolet disinfection of the exhaust gas;

[0065] 4. The waste gas after ultraviolet disinfection is filtered through the first filter 11; then the wind pressure is 80pa by adjusting the booster fan 12; so that the waste gas after the first filtration enters the disinfection pool 13;

[0066] 5. Add 84 disinfectant with an available chlorine concentration of 1000 mg per liter to the disinfection pool 13; sterilize the waste gas through 84 disinfectant;

[0067] 6. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com