Rotor short-circuit ring casting mold

A technology for short-circuiting the rotor and casting molds, which is applied in the directions of rotors, stators, engine components, etc., can solve the problems of unstable quality, poor quality, and unfavorable industrial production and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

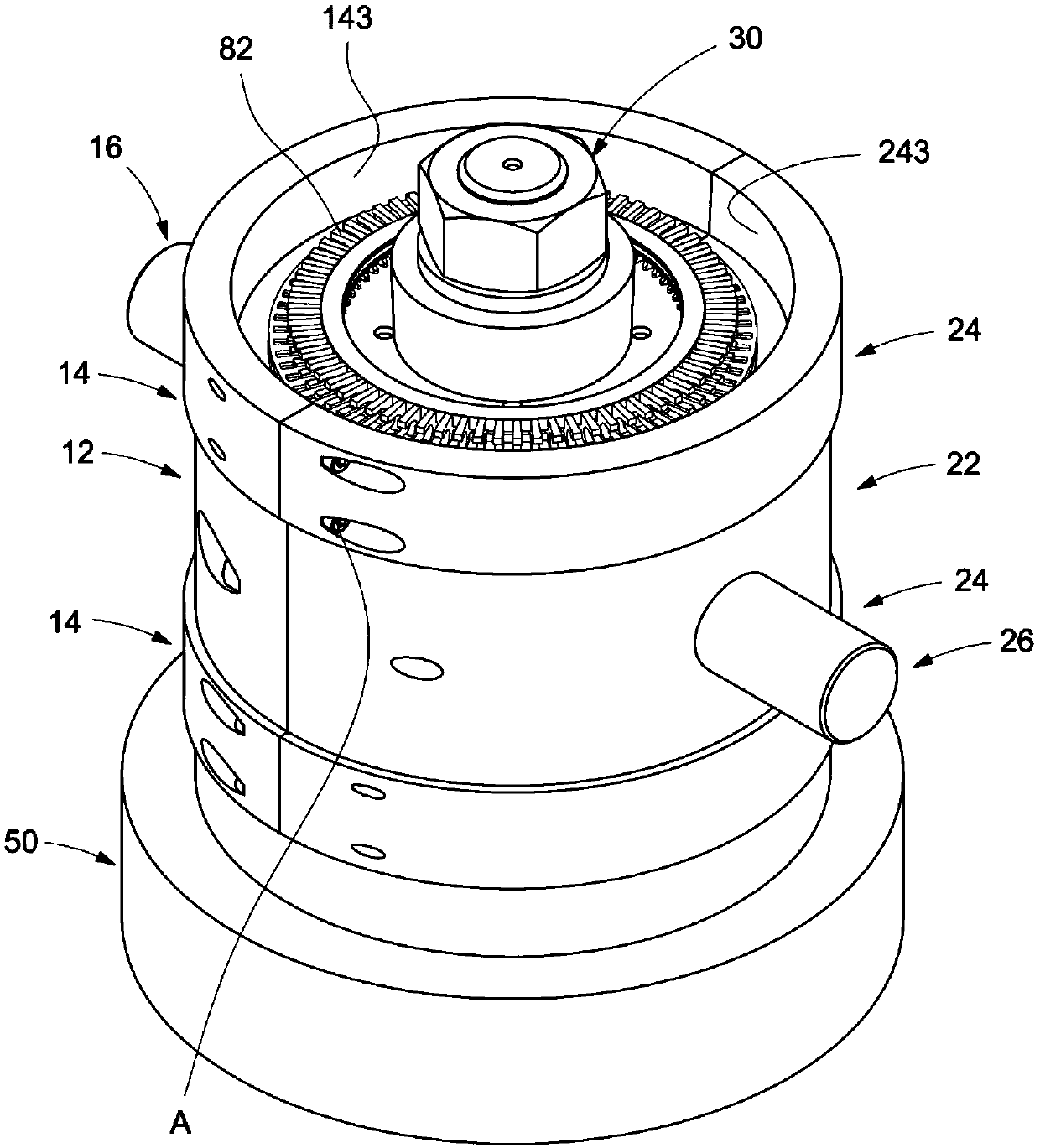

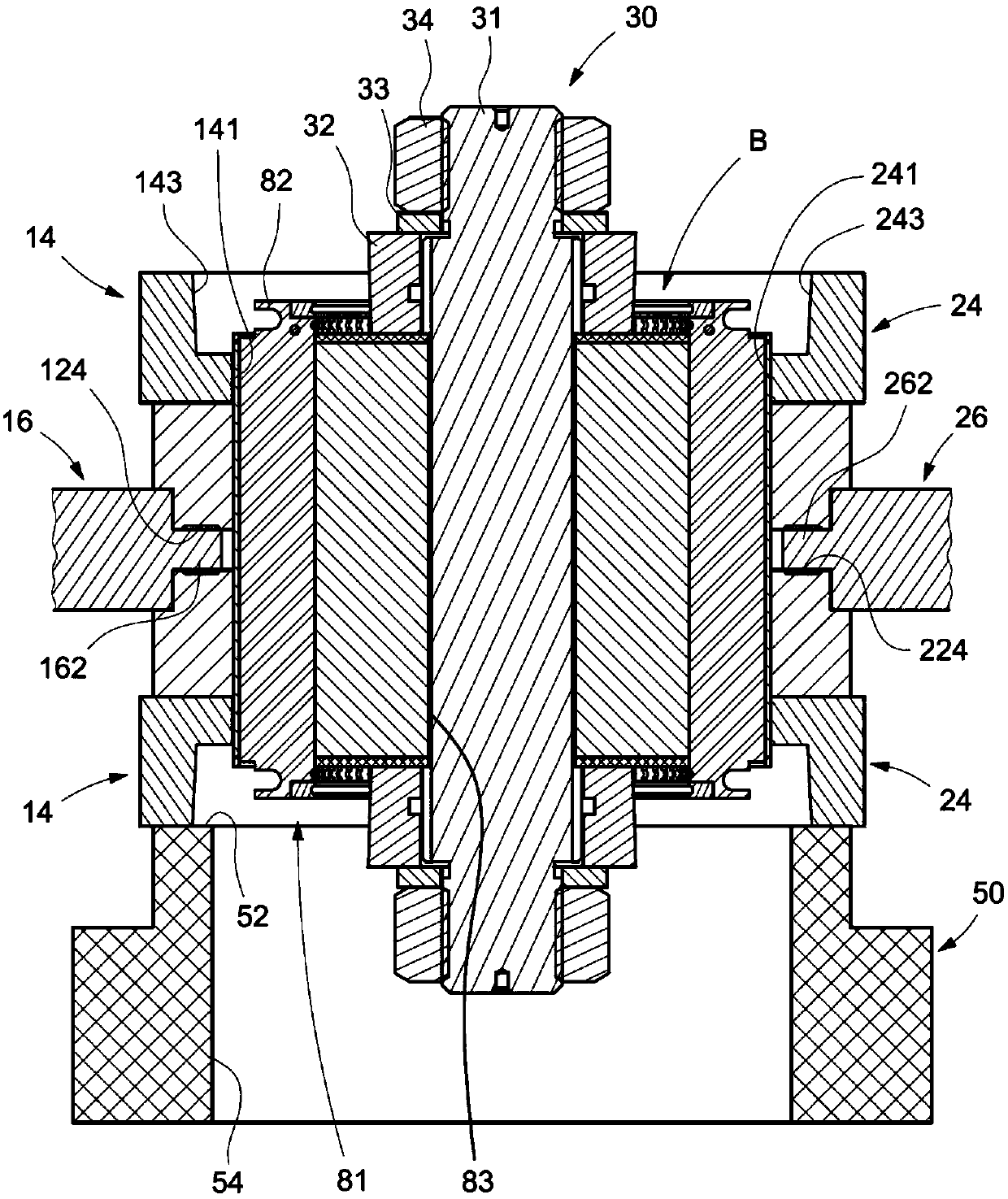

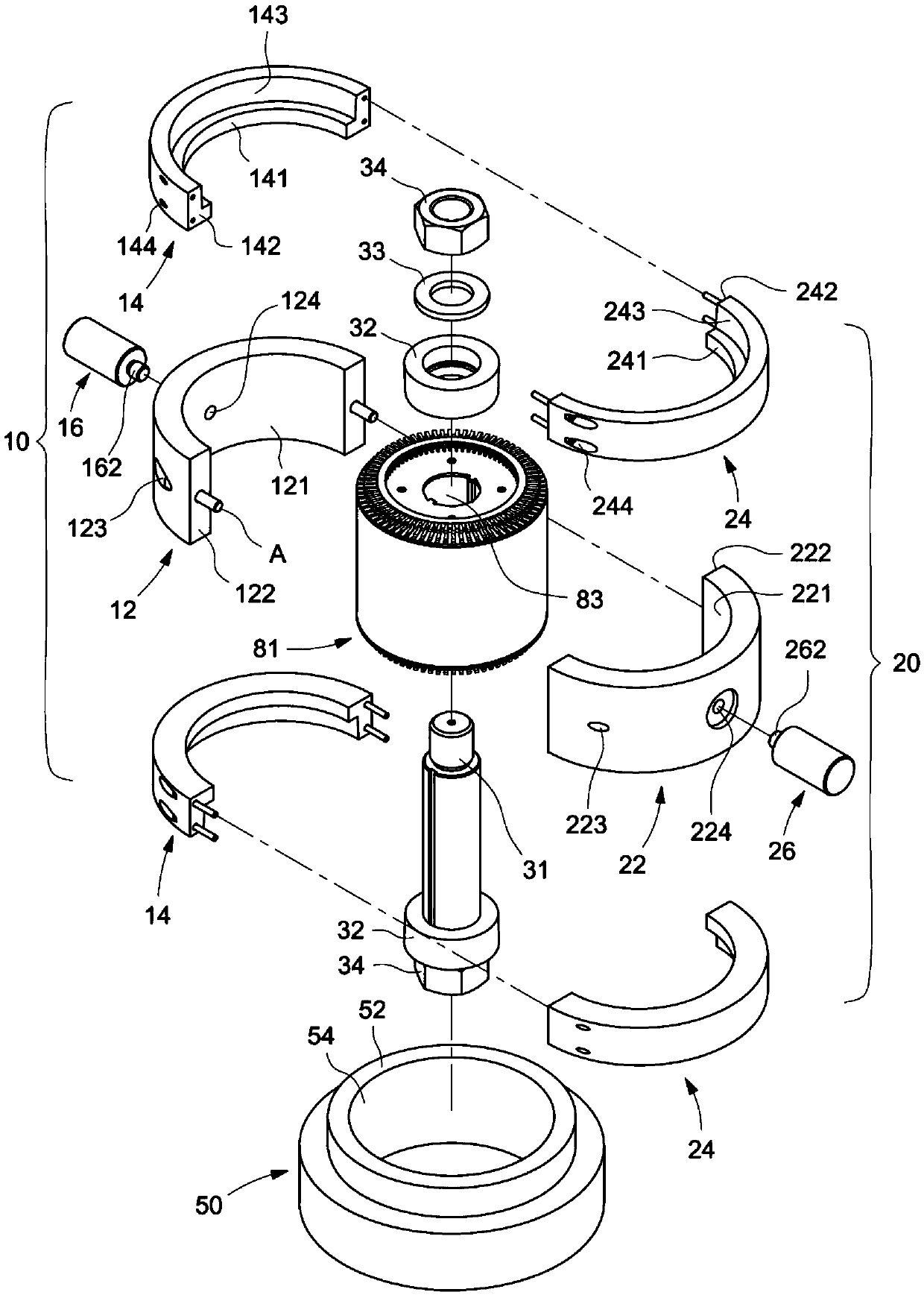

[0031] Please refer to the relevant drawings below to further describe the embodiment of the casting mold structure of the rotor short-circuit ring of the present invention. In order to facilitate the understanding of the implementation of the present invention, the same components are described below with the same symbols.

[0032] The accompanying drawings are for illustration purposes only and are not drawn to original scale. On the other hand, well-known components and steps have not been described in the embodiments in order not to limit the invention unnecessarily.

[0033] see Figures 1 to 4 As shown, the rotor short-circuit ring casting mold of the present invention is used to clamp the iron core 81 radially outer peripheral side of a squirrel cage rotor, surround the iron core 81 and each conductive copper sheet 82 protruding from the end face of the iron core, so as to facilitate The casting process includes a left module 10 , a right module 20 , a center axis modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com