Seat part assembly and semi-annular plate machining tool

A semi-ring, annular plate technology, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve problems such as low processing qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

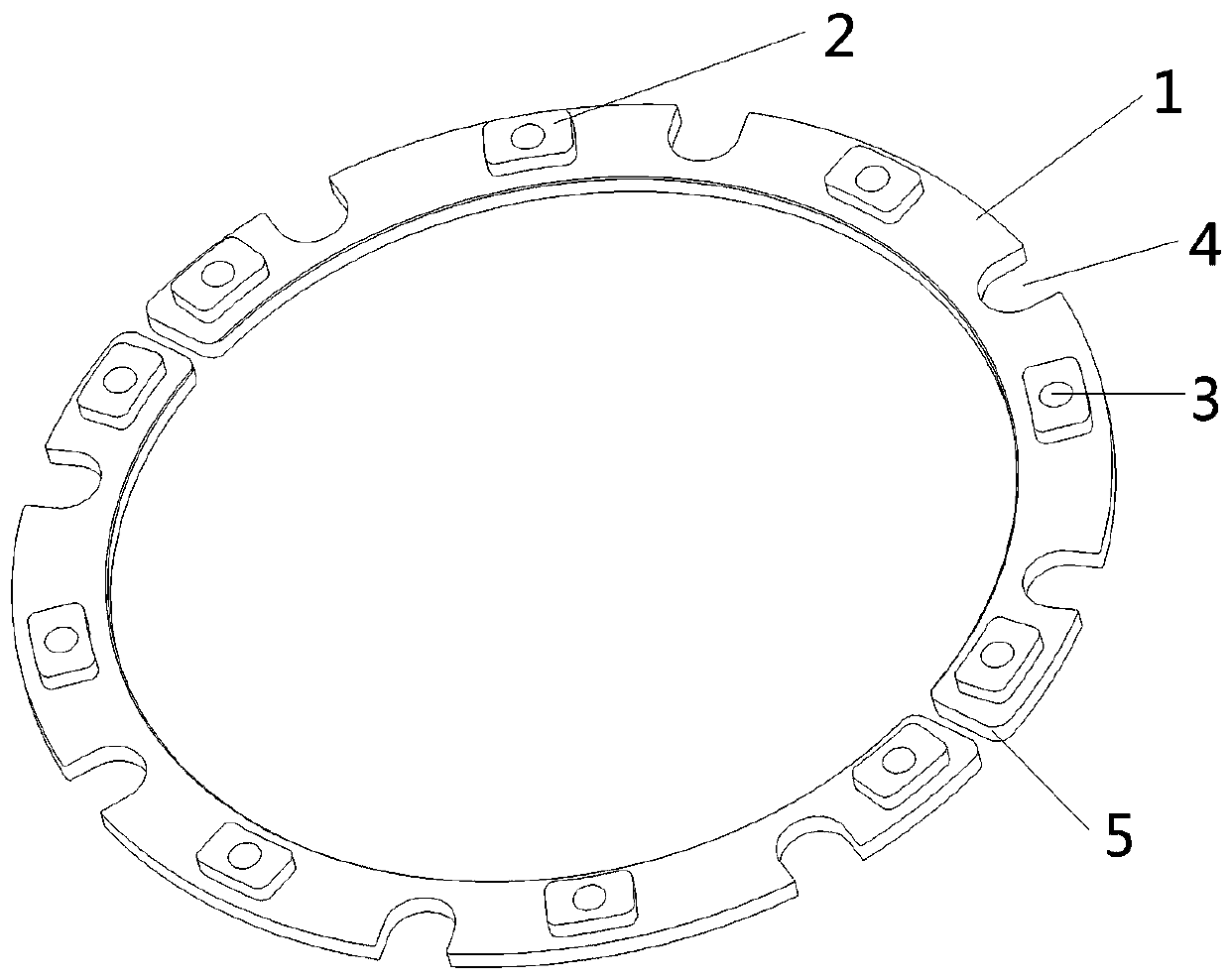

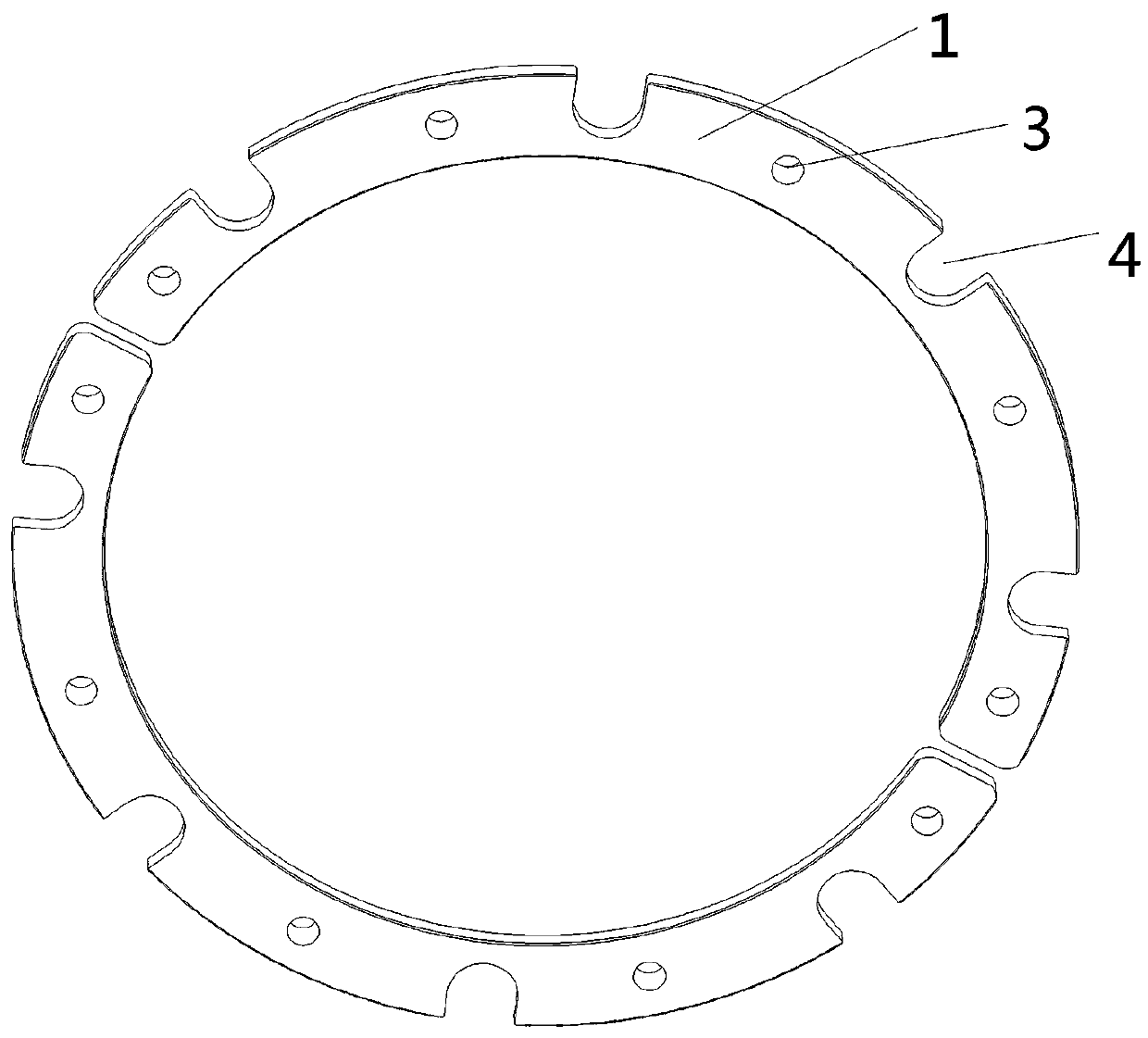

[0058] Such as figure 1 and figure 2 As shown, the seat part assembly of the present invention includes two seat parts 1, the seat part 1 is a semi-circular plate, and the thickness direction of the plate is defined as the up and down direction.

[0059] Such as figure 1 and figure 2 As shown, five bosses 2 distributed at intervals are arranged on the upper surface of the board. Bolt mounting holes 3 on the boss, which are light holes for bolts to pass through.

[0060] Four avoidance grooves 4 are arranged on the upper surface of the plate, and the avoidance grooves 4 are distributed at intervals along the circumferential direction of the plate. The avoidance grooves are U-shaped and run through the plate along the up and down direction. assembly bolts.

[0061] The seat part 1 has two end faces 5 distributed along the circumferential direction, the end faces 5 are planar structures, and each end face 5 and the inner side wall and outer side wall of the seat part 1 ado...

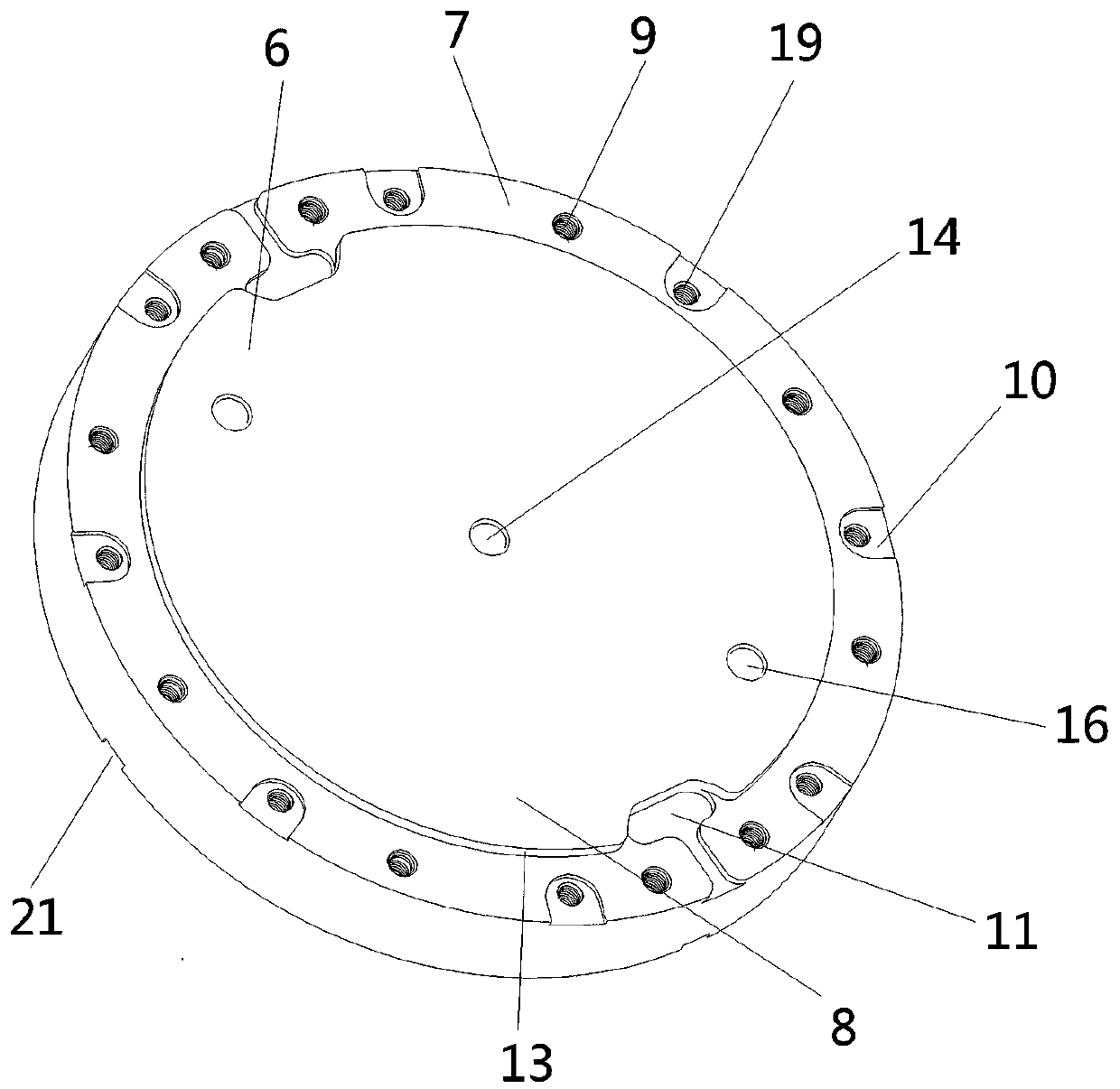

Embodiment 2

[0089] The difference between the semi-annular plate processing tooling in this embodiment and the semi-annular plate processing tooling in the above-mentioned embodiment 1 is that the base in embodiment 1 is provided with a mounting hole for a pressing plate, and the pressing plate is arranged on the base to The workpiece is press-fitted and fixed. In this embodiment, a pressing piece is detachably connected to the base plate through bolts. The pressing piece is in a Z shape as a whole, including the upper horizontal plate section, the lower horizontal plate section and the middle vertical plate. section, the lower horizontal plate section is provided with bolt holes for fastening bolts, and then the pressing parts are detachably fixed on the foundation floor, and the upper horizontal plate section compresses the corresponding annular sheet material, and then the annular The sheet metal is press-fitted and fixed on the support plane.

Embodiment 3

[0091] The difference between the semi-annular plate processing tooling in this embodiment and the semi-annular plate processing tooling in the above-mentioned embodiment 1 is that: the base of the tooling in embodiment 1 is provided with a guide block installation groove and a connecting through hole. The seat is fixed on the foundation base plate for processing. In this embodiment, there are no guide block installation grooves and connecting through holes on the base, and the base is directly clamped and fixed on the vise for processing. Specifically, the vise directly Clamp the outer peripheral surface of the base to fix the base on the corresponding machining platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com