Method for manufacturing conductor frame of LED

A technology of light-emitting diodes and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as warping deformation of metal substrates, deformation of insulating shells, stress concentration of metal substrates, etc., to reduce stress concentration Factor, the effect of avoiding warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

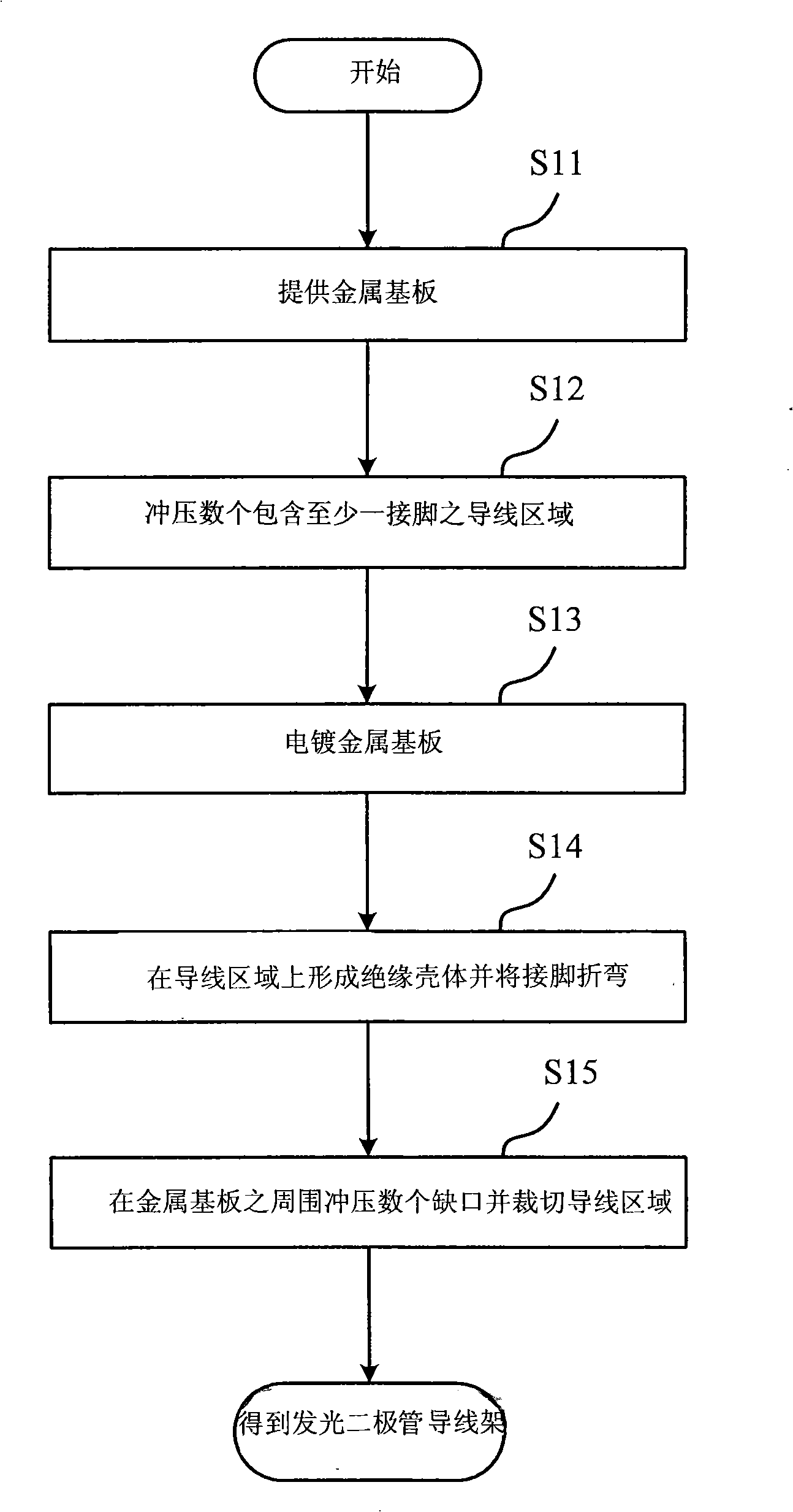

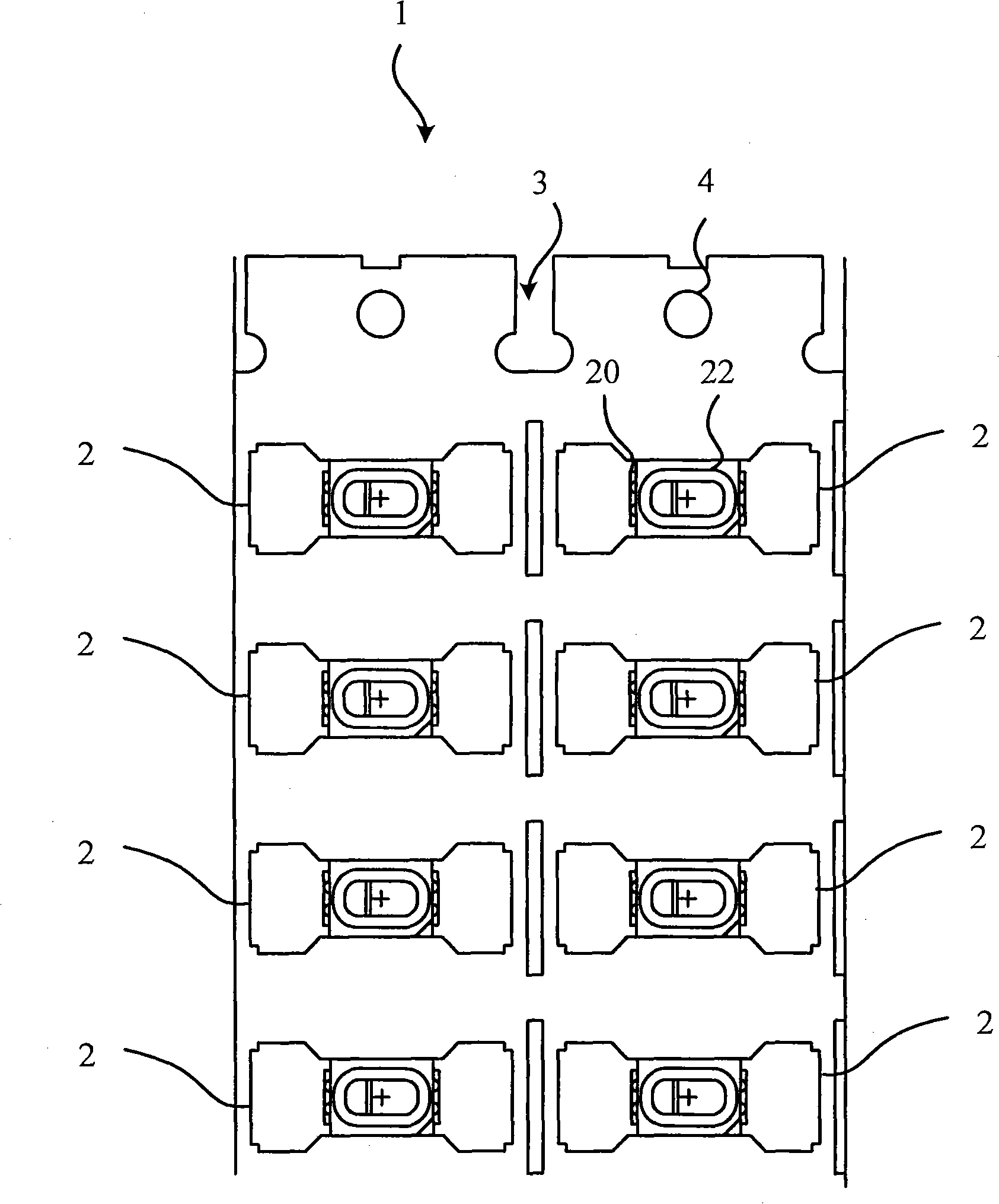

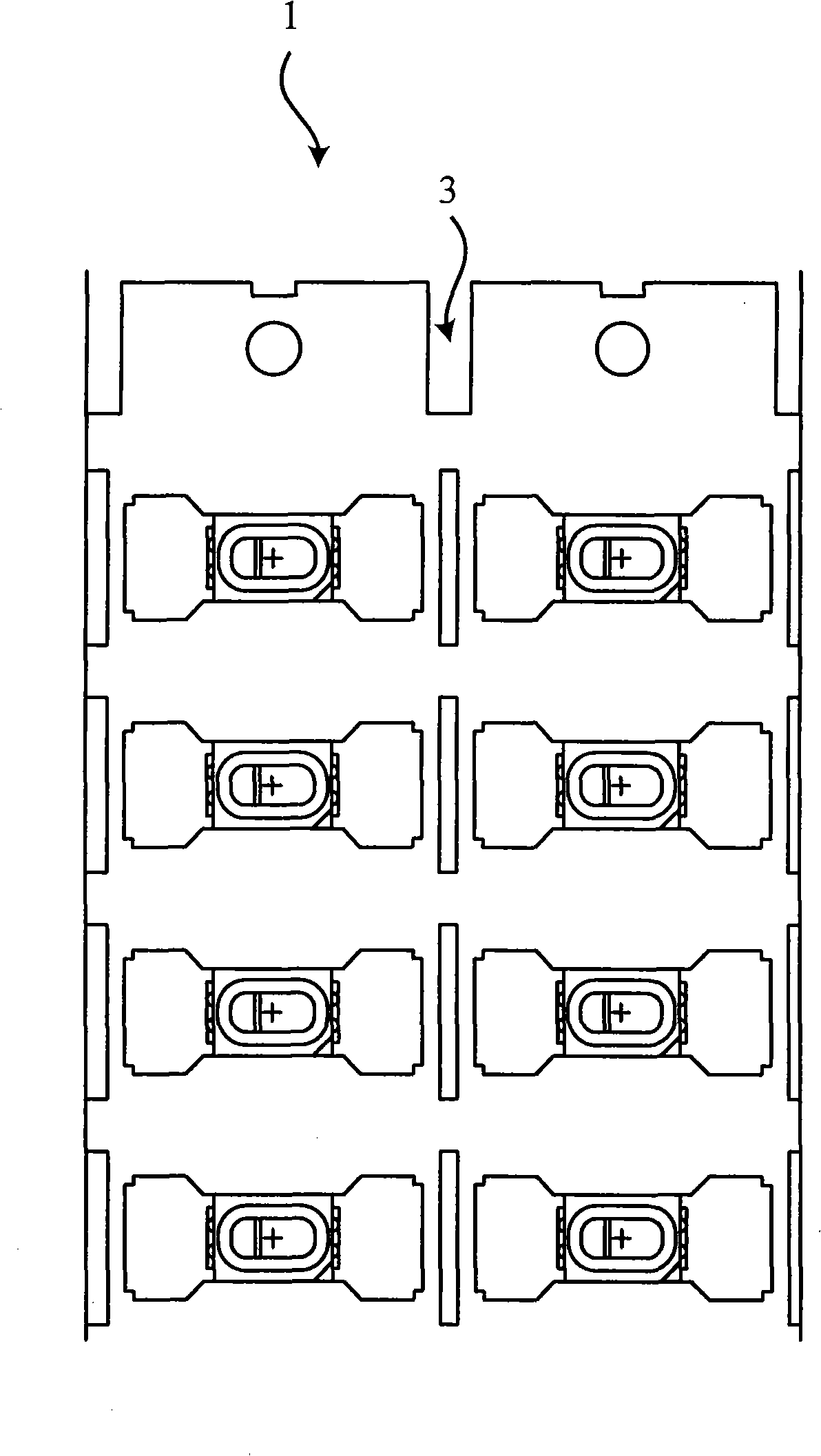

[0024] see figure 1 and Figure 2A , figure 1 is a flow chart illustrating a method for manufacturing a light emitting diode lead frame according to an embodiment of the present invention, Figure 2A is to draw figure 1 A schematic diagram of the elements described in each step. Such as figure 1 As shown, the manufacturing method of the LED lead frame of the present invention includes steps S11-S15.

[0025] Firstly, in step S11 , a metal substrate 1 is provided. Then in step S12 , punching several wire regions 2 , and each wire region 2 includes at least one pin 20 . In step S13 , the metal substrate 1 is electroplated. Afterwards, in step S14 , an insulating casing 22 is formed on each wire region 2 by injection molding, and then the pins 20 are bent. Finally, in step S15 , several notches 3 are punched around the metal substrate 1 , and each wire area 2 is cut to obtain several LED lead frames. In addition, in the above steps, a step of forming a plurality of posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com