Method for detecting optimal placement position of cigarettes in constant-temperature and constant-humidity box

A technology of constant temperature and humidity chamber and optimal position, which is applied in the direction of measuring devices, utilizing fluid devices, instruments, etc., can solve problems such as large differences in results, achieve remarkable results, stable products, and simple and reliable methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

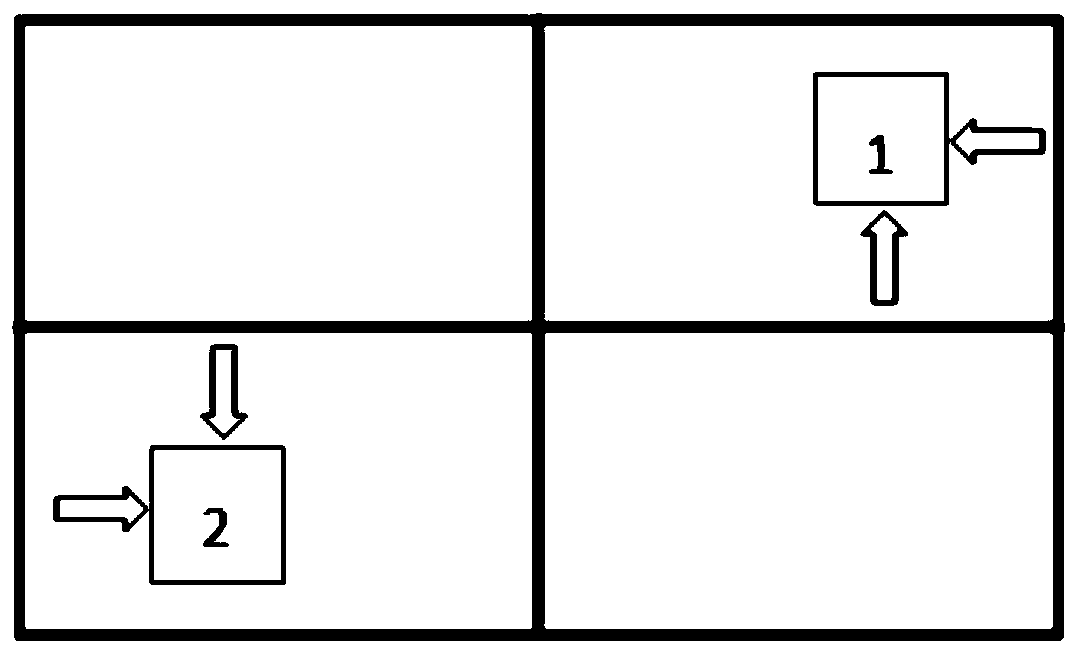

[0061] A method for detecting the best position of cigarettes in a constant temperature and humidity box, comprising the following steps:

[0062] Step (1), place three trays on average in the card slot inside the constant temperature and humidity box according to the distance from top to bottom, which are respectively recorded as the upper, middle and lower layers; Measure the working surface, the upper layer and the lower layer are respectively placed at the middle distance between the middle layer and the top and bottom of the box;

[0063] Step (2), place 2 measurement points on the upper layer, which are respectively located in the front left and rear right;

[0064] The distance between the measuring probe position of the rear right anemometer and the rear box wall is 12% of the inner tank depth of the constant temperature and humidity box, and the distance from the right box wall is 8% of the inner tank width of the constant temperature and humidity box; Measure the wi...

Embodiment 2

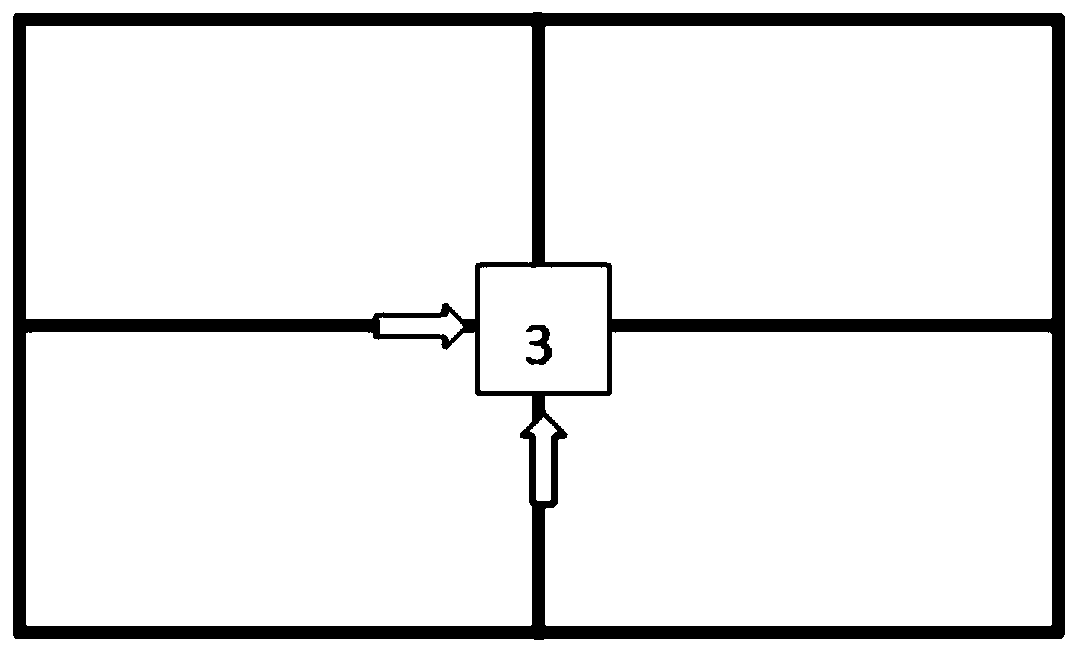

[0088] A method for detecting the best position of cigarettes in a constant temperature and humidity box, comprising the following steps:

[0089] Step (1), place three trays on average in the card slot inside the constant temperature and humidity box according to the distance from top to bottom, which are respectively recorded as the upper, middle and lower layers; Measure the working surface, the upper layer and the lower layer are respectively placed at the middle distance between the middle layer and the top and bottom of the box;

[0090] Step (2), place 2 measurement points on the upper layer, which are respectively located in the front left and rear right;

[0091] The distance between the measuring probe position of the rear right anemometer and the rear box wall is 18% of the depth of the inner tank of the constant temperature and humidity box, and the distance between the right side of the box wall is 15% of the width of the inner tank of the constant temperature and...

Embodiment 3

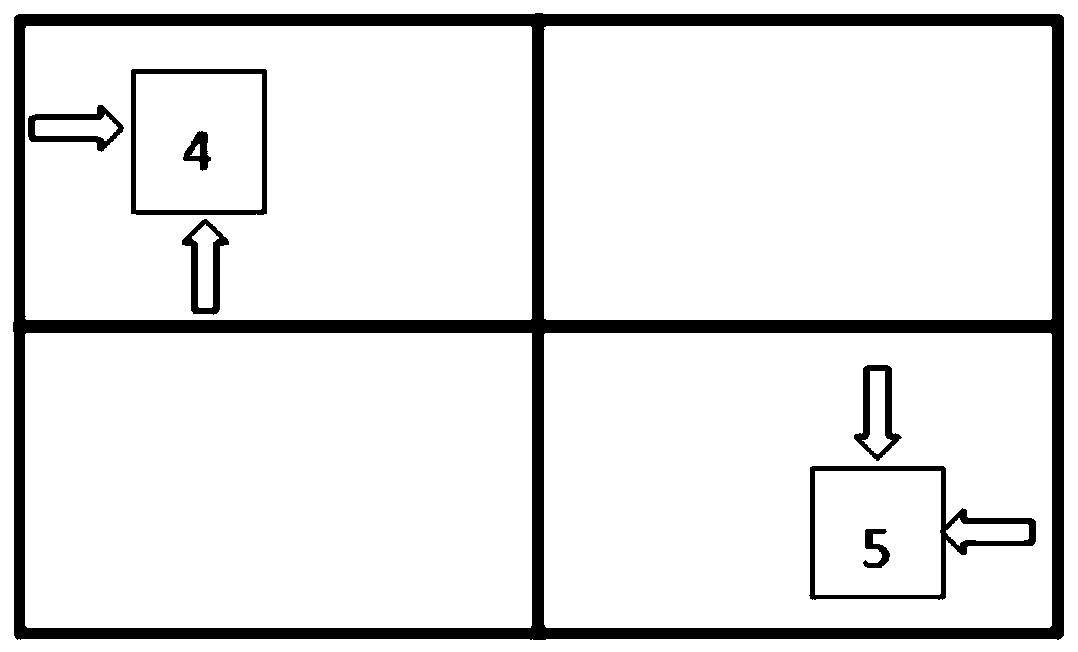

[0117] A method for detecting the best position of cigarettes in a constant temperature and humidity box, comprising the following steps:

[0118] Step (1), place three trays on average in the card slot inside the constant temperature and humidity box according to the distance from top to bottom, which are respectively recorded as the upper, middle and lower layers; Measure the working surface, the upper layer and the lower layer are respectively placed at the middle distance between the middle layer and the top and bottom of the box;

[0119] Step (2), place 2 measurement points on the upper layer, which are respectively located in the front left and rear right;

[0120]The distance between the measuring probe position of the rear right anemometer and the rear box wall is 14% of the depth of the inner liner of the constant temperature and humidity box, and the distance between the right side of the box wall is 10% of the width of the inner liner of the constant temperature an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com