Dynamic balance adjusting system of centrifugal machine

A technology of balance adjustment and transmission system, applied in the field of centrifuges, can solve the problems of large installation space of the rotor arm of the centrifuge, complex structure of the dynamic balance adjustment system, increased load of the rotor arm of the centrifuge and design difficulty, etc. Small space, simple structure, and the effect of improving dynamic balance adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is further described in detail below, but the protection scope of the present invention is not limited to the following description.

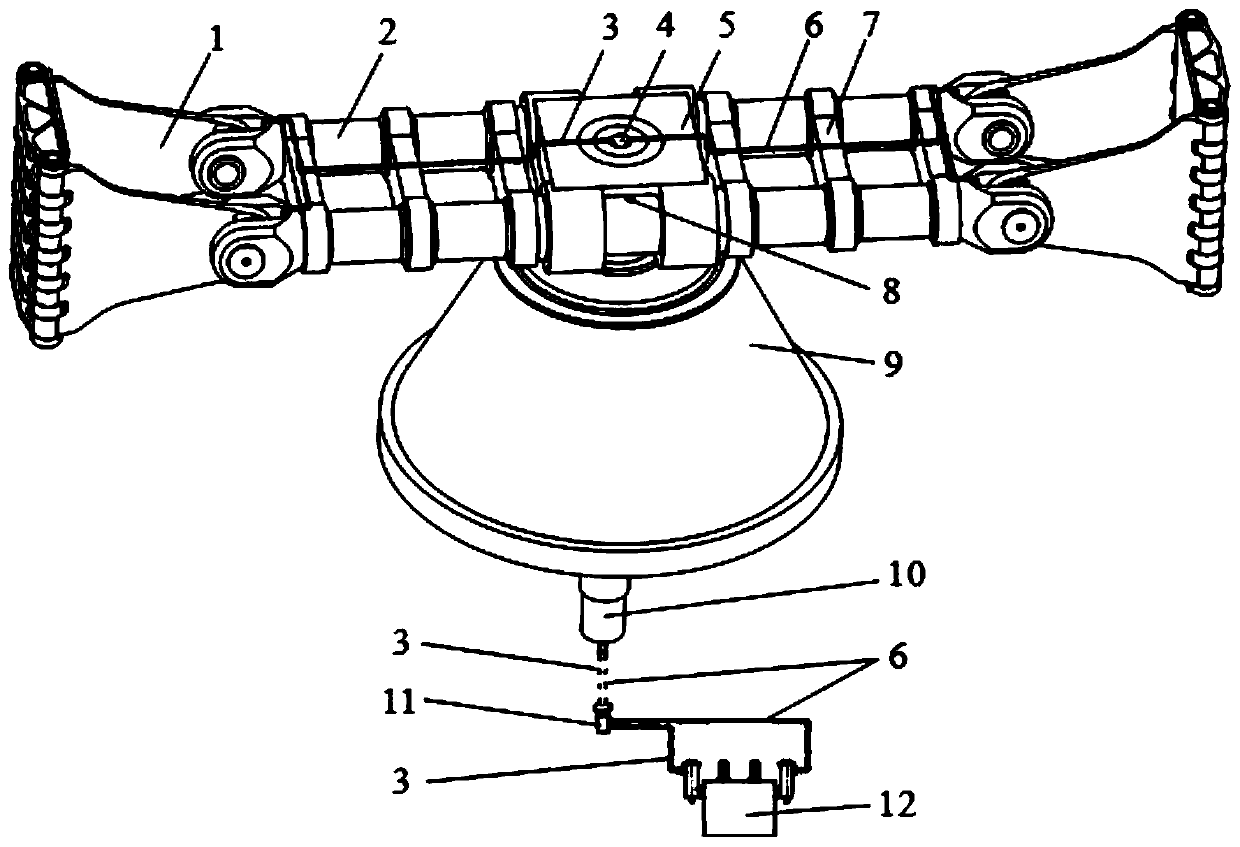

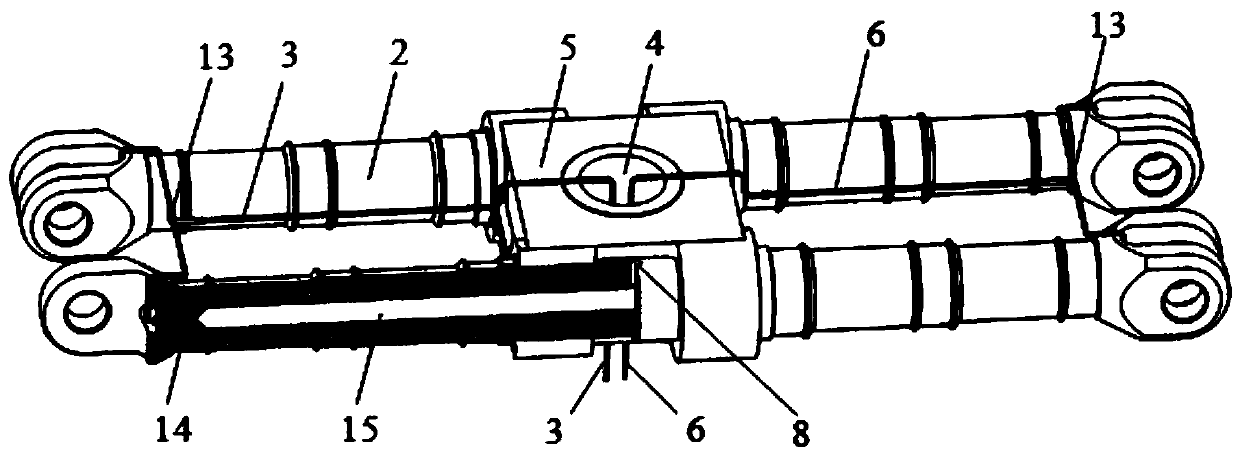

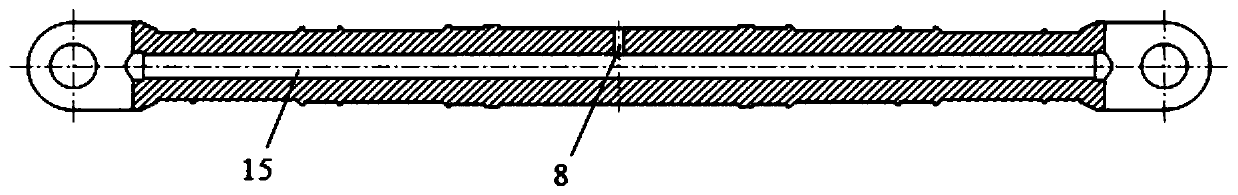

[0029] Such as figure 1 As shown, the rotating system of the centrifuge is composed of 2 sets of hanging baskets 1, 2 tension belts 2, 1 set of rotating arm supports 5, 6 sets of positioning rings 7 and pin shafts, among which 2 tension belts 2 pass through the rotating arm supports 5 and 6 sets of positioning rings 7 are connected as a whole to form a jib. The parts installed on the hanging basket 1, the arm frame and the arm frame constitute a rotating arm. And 2 sets of hanging baskets 1 are suspended on the tension band 2 two ends by pin shafts. The transmission system 9 is fixed on the civil foundation, and the upper end of the main shaft 10 of the internal transmission system is fixedly connected with the arm support 5 through an expansion sleeve, so that the main shaft of the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com