Integrated type fertilizer processing platform

A processing platform and integrated technology, applied in the field of machinery, can solve the problem of low efficiency of fertilizer sieving, and achieve high-efficiency sieving without affecting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

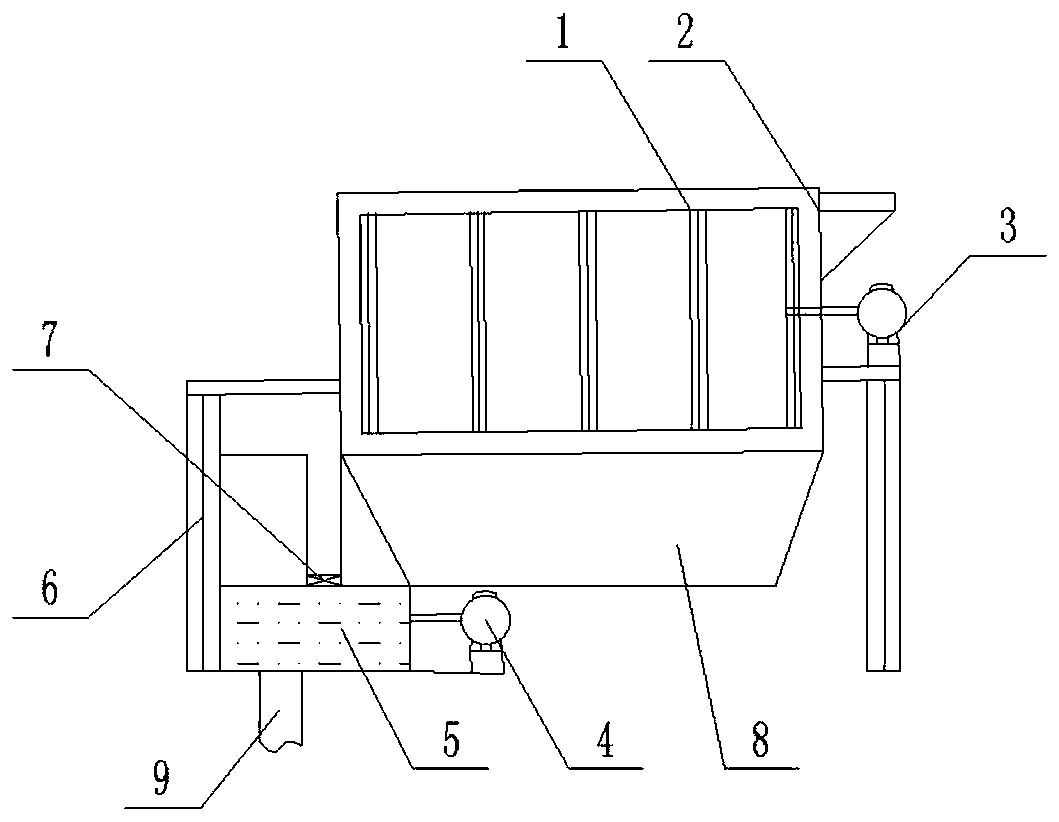

[0026] An integrated fertilizer processing platform provided by a preferred embodiment of the present invention,

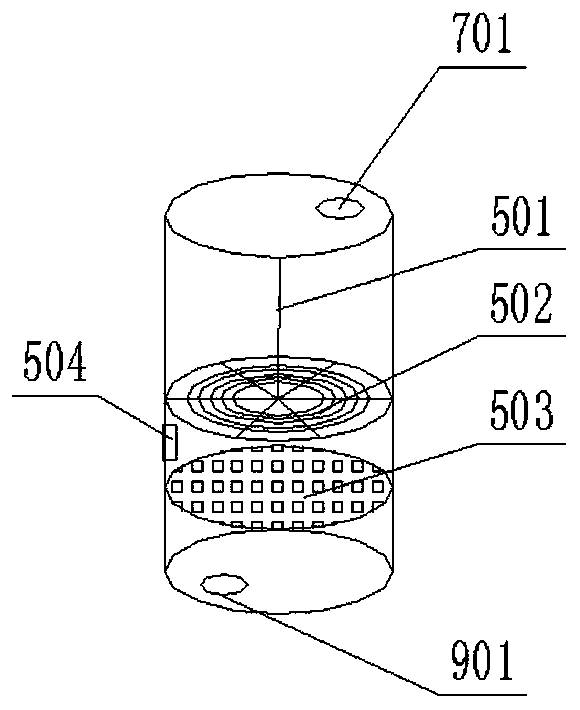

[0027] An integrated fertilizer processing platform, including a first crushing chamber 1, support columns 6 are arranged on both sides of the first crushing chamber 1, a first slag outlet 7 and a first discharge outlet 8 are arranged at the bottom, and a cylindrical The second crushing chamber 5, the second crushing chamber 5 is provided with a sieve tray 503 with small holes to divide its interior into upper and lower parts; the upper part includes a cover plate with a second feeding port 701, and the center of the cover plate is provided with a bottom connected to the grinding chamber. The lower part of the rotating shaft 501 of the disk 502 includes a bottom plate with a second discharge port 901 .

[0028] When working: the double crushing mode is adopted; after the crushing is qualified, it enters the first discharge port 8 or the second discharge port 901 t...

Embodiment 2

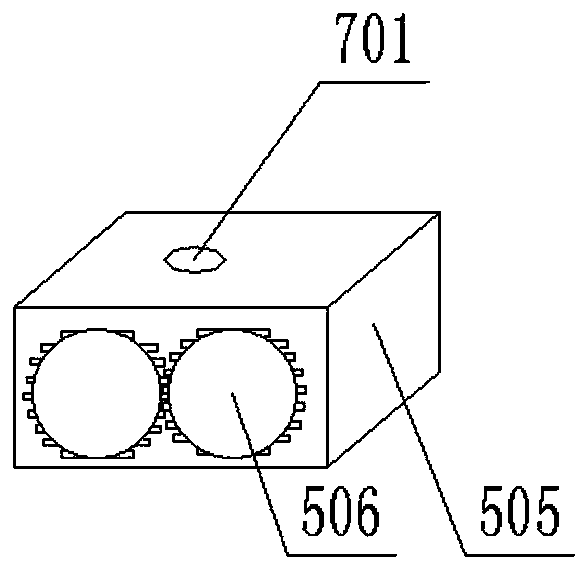

[0031] In this embodiment, on the basis of the first embodiment, a squeeze box 505 is provided below the second feed port 701, and the squeeze box 505 is rectangular and is located in the gap between the rotating shaft 501 and the side wall. The extrusion box 505 includes at least two extrusion rollers 506, and the extrusion rollers 506 are cylinders with convex teeth. The minimum gap between any two squeeze rollers 506 is larger than the diameter of the small hole of the sieve plate 503 . The first crushing chamber 1 includes a casing and a screen, and the screen is connected to the first motor 3 through a Pozidella frame assembly. The second material outlet 901 is connected with the material guide pipe 9 . The side wall of the second crushing chamber 5 is provided with a second slag outlet 504 that can be switched on and off, and the second slag outlet 504 is located above the sieve tray 503 .

[0032] When working: the squeeze box 505 does not affect the work of the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com