Cross-shaped feeding device and feeding method

A cross and cross beam technology, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of back-and-forth ferrying of the grabbing device, poor continuity, and large footprint, and improve space utilization and operation. Strong stability and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

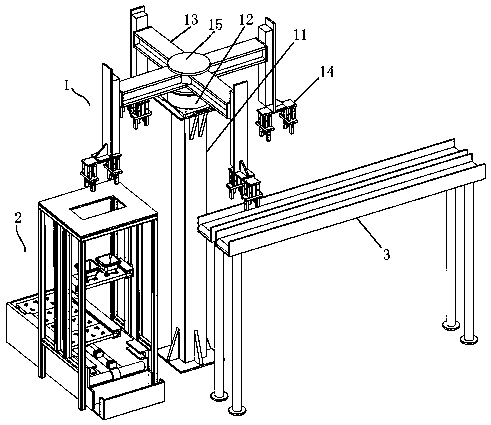

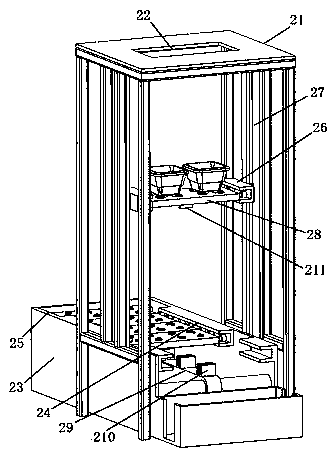

[0026] Example 1. A cross feeding device, constituted as figure 1 and 2 As shown, it includes a cross rotary feeding mechanism 1; the cross rotary feeding mechanism 1 includes a support column 11, and the top of the support column 11 is provided with a drive motor 12, and the drive motor 12 is connected with a cross beam 13 formed by crossing two beams, and the cross beam Each beam end of 13 is provided with a grasping manipulator 14 that can move vertically; below the two grasping manipulators 14 that are arranged perpendicular to each other, a meal tray loading mechanism 2 and a food box conveyor belt 3 are respectively arranged. The structure of grabbing the manipulator 14 to move vertically can be arranged conventionally, for example, a cylinder can be used to realize the vertical movement of the grabbing manipulator 14 .

[0027] The aforementioned drive motor 12 is connected to the cross beam 13 via a conductive slip ring 15 . The connection structure among the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com