Anti-buckling assembled tunnel combined structure supporting system and construction method thereof

A combined structure and anti-buckling technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as buckling failure of arch structures, and achieve the effects of enhancing bearing capacity, improving operating environment, and reducing local buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

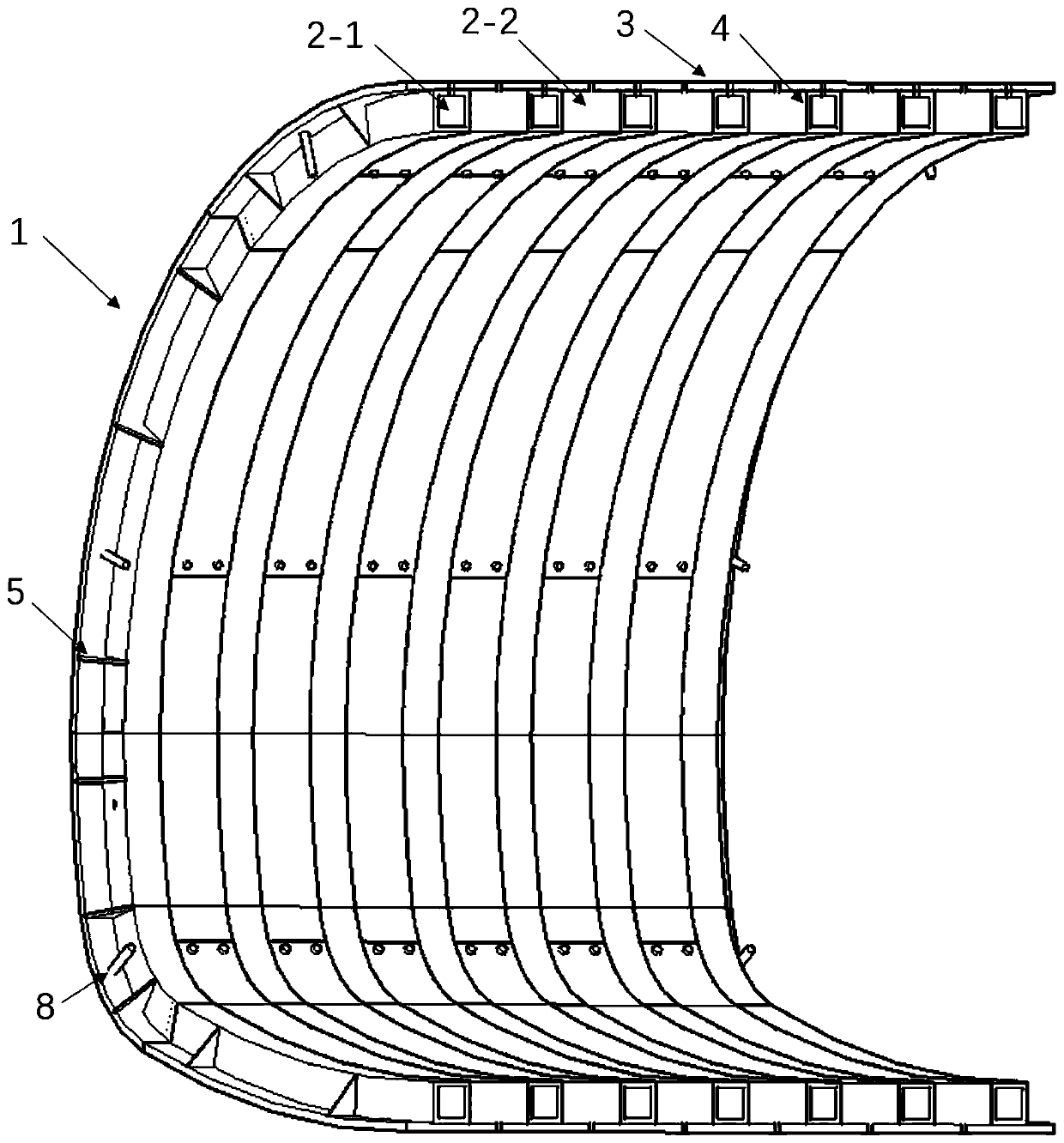

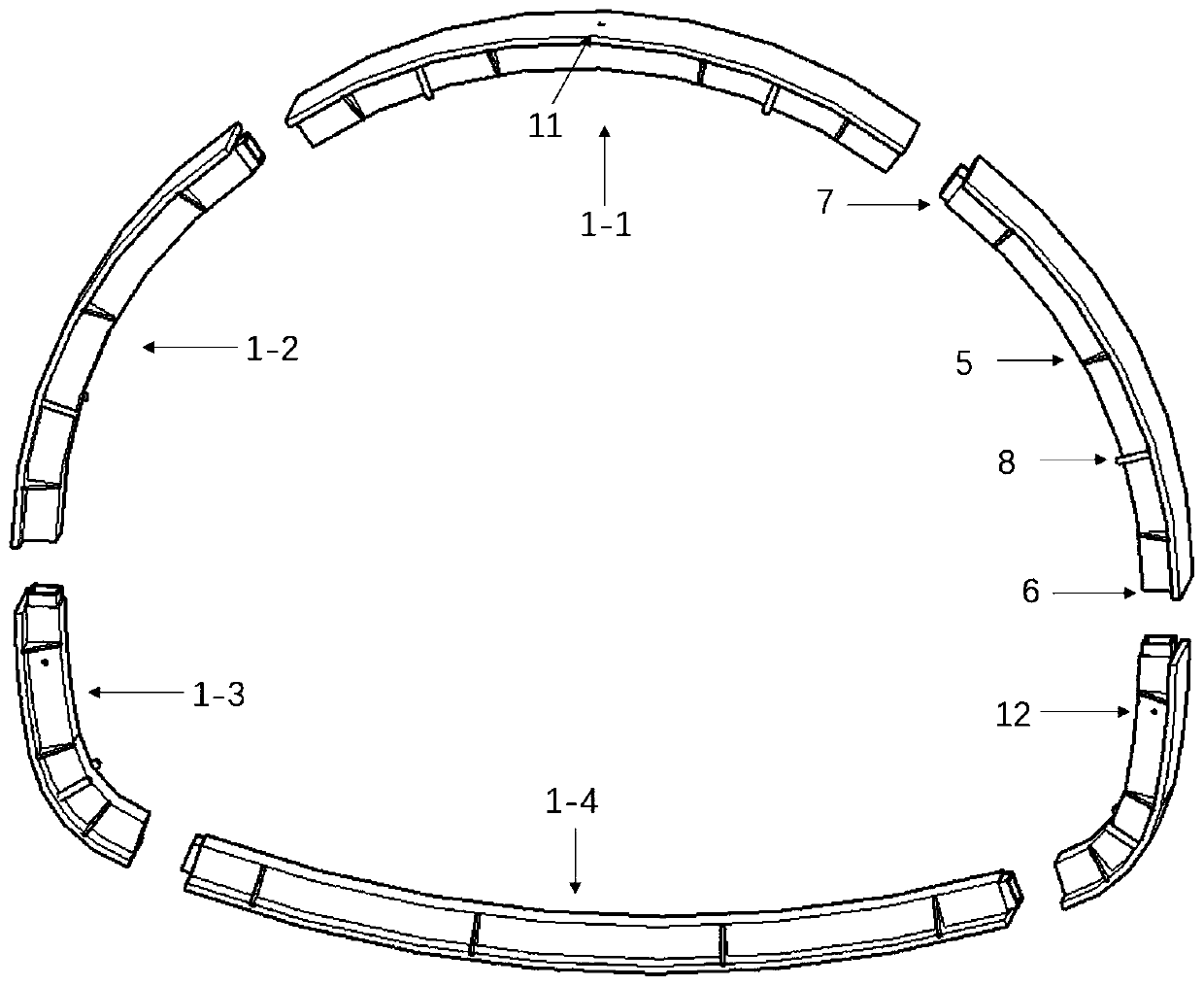

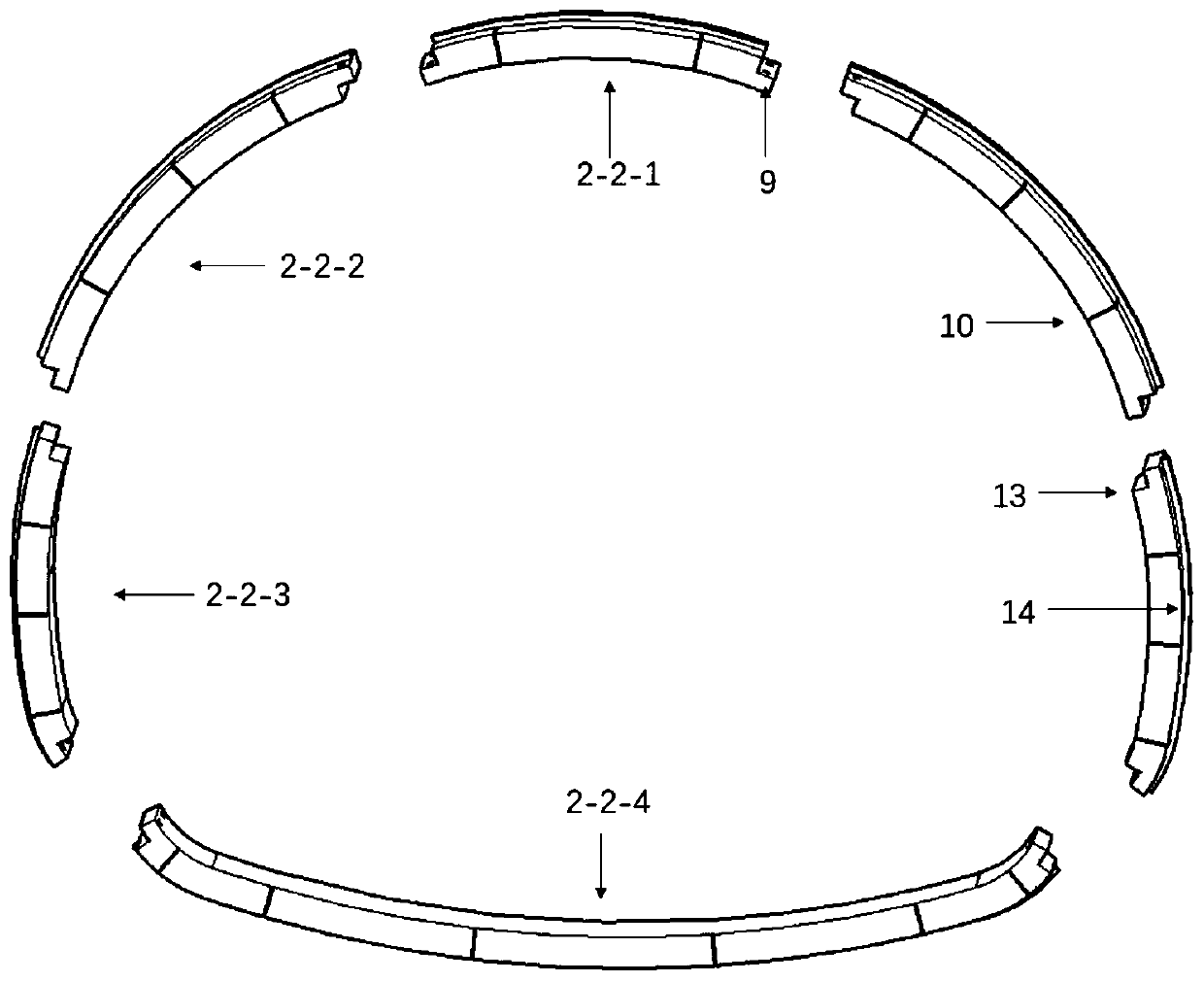

[0059] Such as figure 1 As shown, a buckling-resistant assembled tunnel composite structure support system of the present invention includes three parts: a buckling-resistant composite arch frame 1, an inner concrete 2-1 and a prefabricated concrete lining 2-2. Anti-buckling combined arch 1 includes wing plate 3, core tube 4, reinforcement angle plate 5 and fixing bolts 8; ; The core pipe 4 is poured with in-pipe concrete 2-1, and a prefabricated concrete lining 2-2 is installed between the adjacent anti-buckling composite arches 1.

[0060] The anti-buckling combined arch 1 is used as the bearing part of the arch. The anti-buckling composite arch frame is used to immediately close the excavation space to form the first-floor support structure of the support system, which bears the surround...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com