A testing device suitable for short protein fibers

A testing device, short fiber technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the problem that can not meet the testing requirements of protein short fiber, short fiber can not be used for tensile test, fiber bundle slippage etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

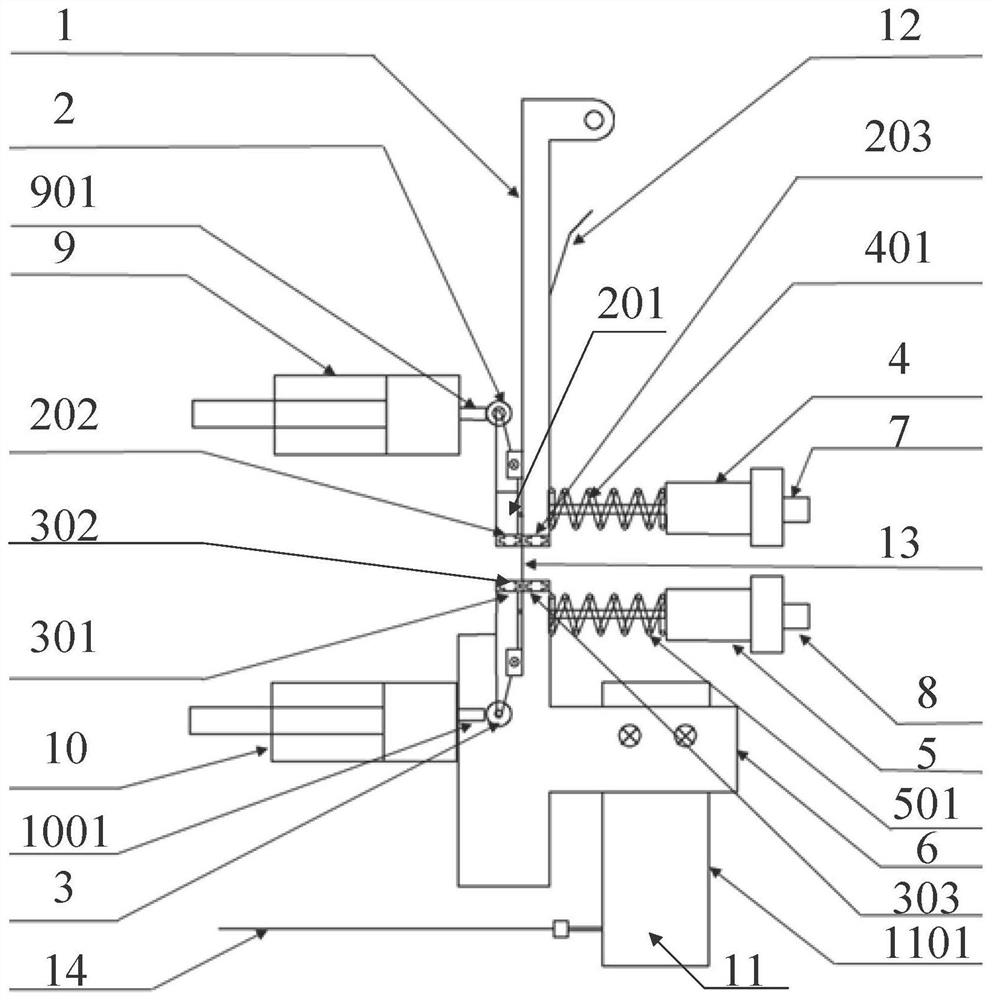

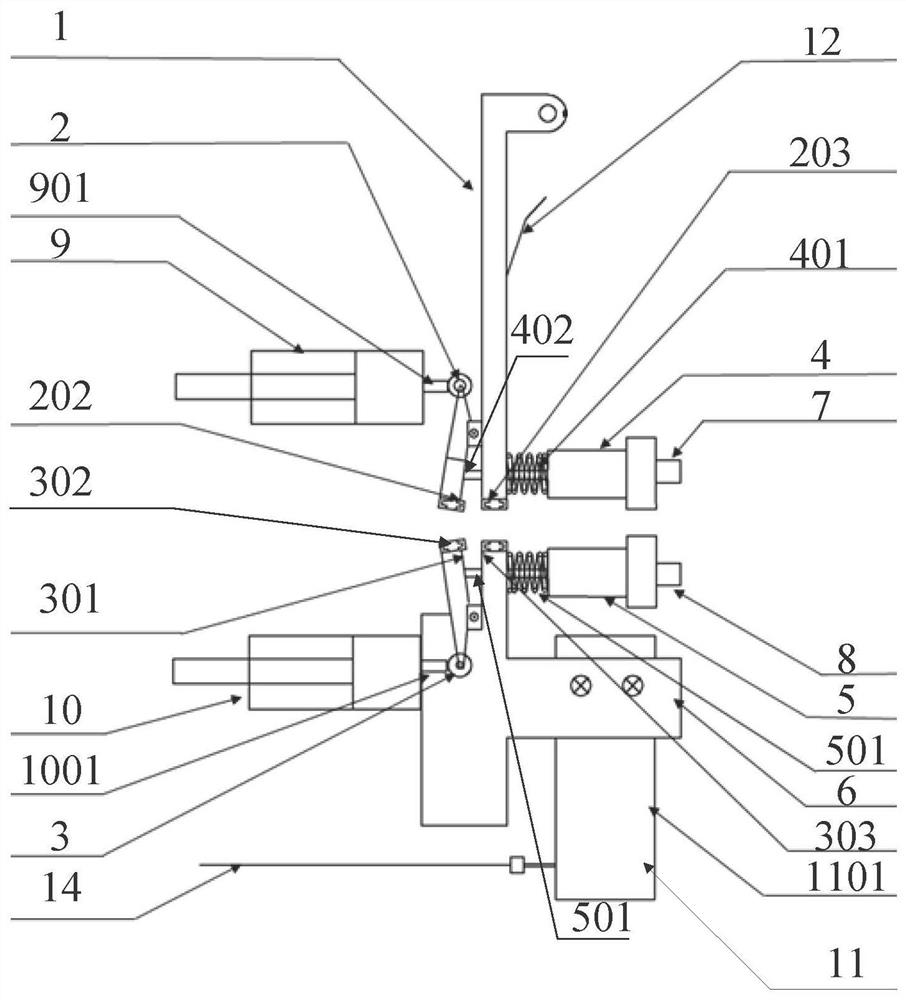

[0058] The invention provides a testing device suitable for short protein fibers. Among them, the test device suitable for short protein fibers includes a load sensing connection device 1 , an upper clamping device 2 , a lower clamping device 3 , an upper clamping force control device 4 and a lower clamping force control device 5 .

[0059] The upper clamping device 2 is installed on the load sensing connection device 1, and the load sensing connection device 1 is connected with the tension sensor. Disassembly, the invention discloses that the load sensing connection device 1 and the tension sensor are detachably connected, and the load sensing connection device 1 and the tension sensor are connected with interference fit, that is, the metal rod of the tension sensor is connected to the load sensing connection device 1 metal hole socket.

[0060] The lower clamping device 3 can be installed on the test system support block 6, in order to facilitate the disassembly and assembl...

Embodiment 2

[0064] In the second embodiment provided by the present invention, the structure applicable to the short protein fiber testing device in this embodiment is similar to that suitable for the short protein fiber testing device in Embodiment 1, and the similarities will not be repeated here. Only the differences are presented.

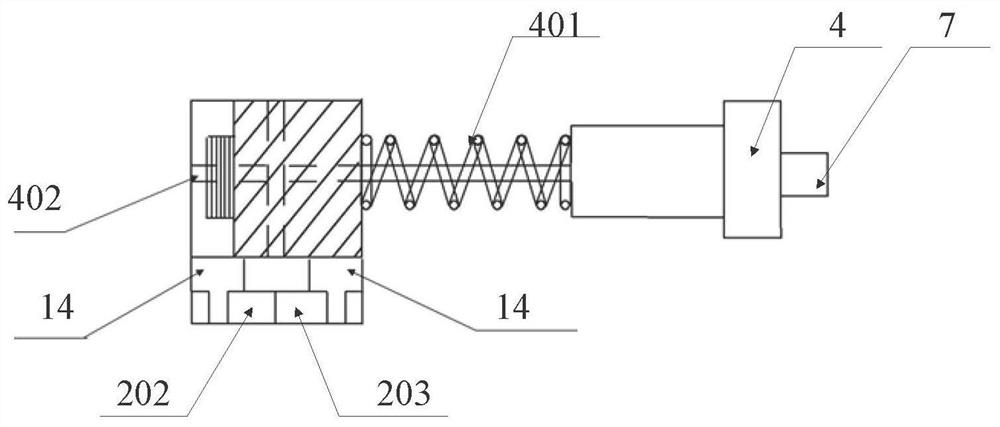

[0065] In this embodiment, the present invention specifically discloses that the upper clamping device 2 includes a first pressing bar 201, a first clamping piece 202 and a second clamping piece 203, and the load sensing connecting device 1 is provided with a first fulcrum base, a second A pressing rod 201 is hinged on the first fulcrum, and the clamping end of the first pressing rod 201 is connected with the first clip 202 . The second clip 203 is fixed on the load sensing connection device 1, the upper clamp force control device 4 is connected to the first clip 202, and can control the clamping force between the first clip 202 and the second clip 203, T...

Embodiment 3

[0092] The present embodiment uses the short protein fiber testing device provided in Example 2 to carry out the test. The specific embodiment takes 3.0 mm hair short fiber as the test object. For the test method, see figure 1 .

[0093] The main component of short hair fibers is keratin, which is hard and smooth, with a diameter between 40 μm and 400 μm.

[0094] First, assemble the four clips into the upper clamping device 2 and the lower clamping device 3, and use sandpaper to polish the clip surfaces of each clip to make each pair of clips clamp in a natural state without gaps; then, assemble the The upper clamping device 2 and the load sensor are socketed through the sensor metal rod, and the sensing metal rod is fixed on the tensile instrument through the elastic metal sheet 12 to ensure that the entire upper chuck device maintains a vertical direction; then, the assembled The lower clamping device 3 is assembled on the lower chuck movement control device 11; then, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com