Miniature sample gas automatic sample injection system for gas chromatography

A technology of automatic sampling and gas chromatography, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the test results cannot be guaranteed to be accurate and reliable, can not meet the gas chromatography detection, and the volume is inconsistent, so as to achieve accurate and reliable test results and low cost. Low, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

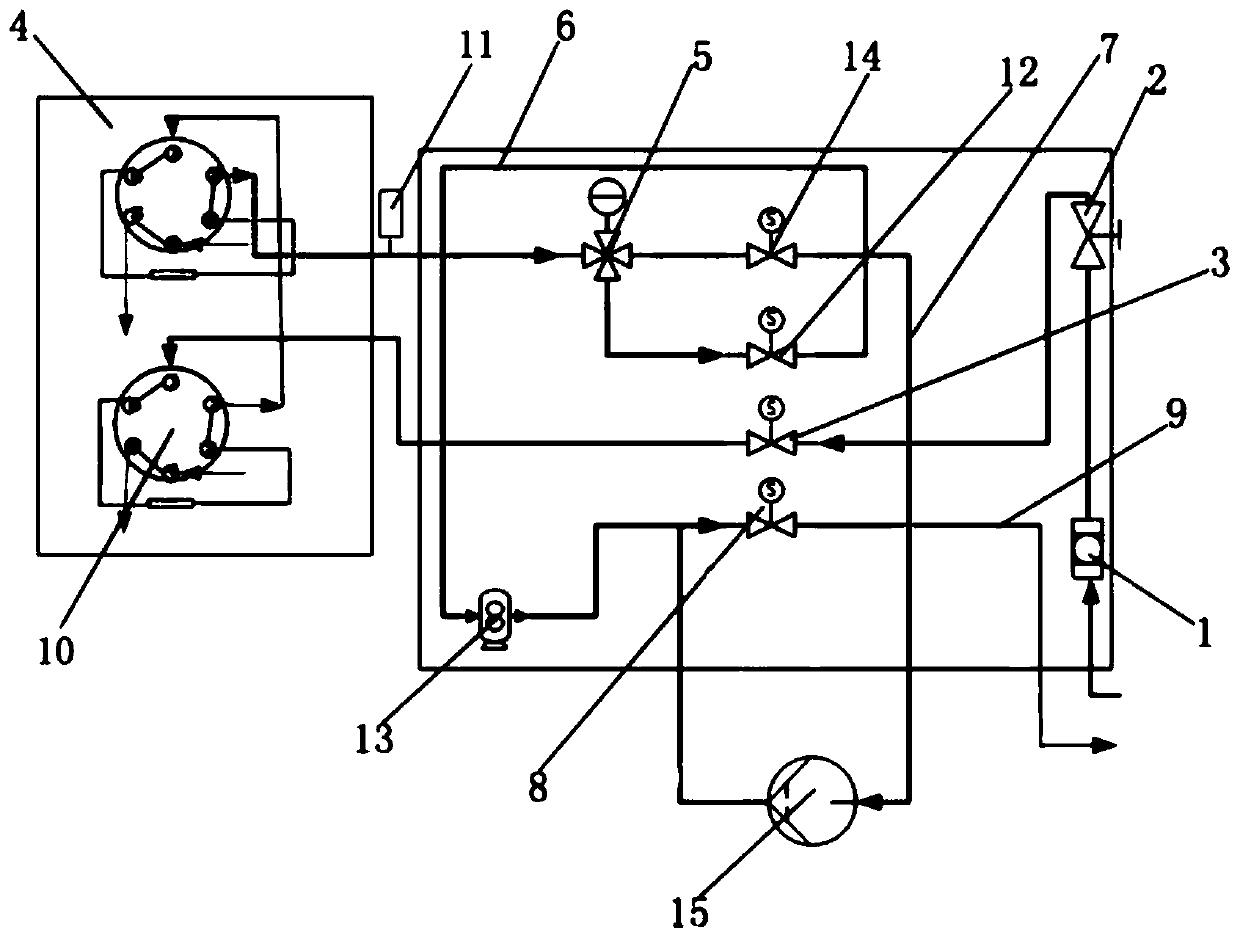

[0026] Such as figure 1 As shown, it is used for gas chromatography sample gas miniature automatic sampling system, including filter 1, fine-tuning valve 2, first solenoid valve 3, valve mechanism 4, pressure sensor 5, first flow path 6, second flow path 7, Second solenoid valve 8, gas outlet pipe 9, temperature sensor 11, six-way valve 10, fourth solenoid valve 12, motor 13, third solenoid valve 14, vacuum pump 15 and automatic controller. Among them, the filter 1 is used to access the gas and filter out the impurity particles in the gas; the fine-tuning valve 2 is connected to the filter 1 pipeline, which is used to control the opening of the pipeline and can adjust the sampling speed; the first solenoid valve 3 It is connected with the fine-tuning valve 2 pipeline to control the opening and closing of the pipeline; the valve-through mechanism 4 is connected with the pipeline of the first electromagnetic valve 3 and connected with an external detection mechanism (such as: a ...

Embodiment 2

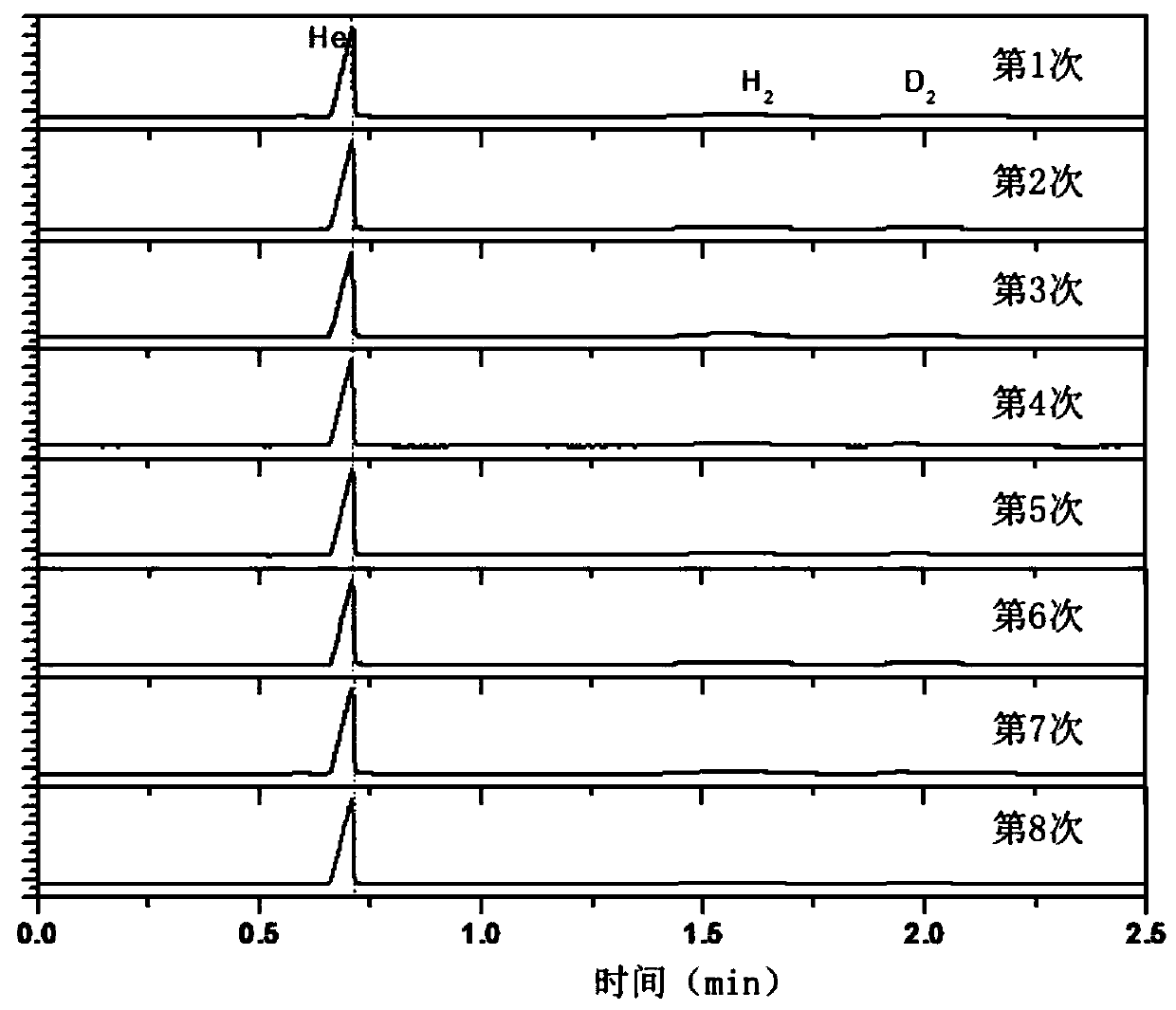

[0029] The following are the test results of atmospheric pressure injection.

[0030] Under normal working conditions, connect the filter 1 to the air intake pipeline. After the instrument is stabilized, when the first solenoid valve 3, the second solenoid valve 8, the fourth solenoid valve 12 and the third solenoid valve 14 are in the closed state, Open the filter 1, the first solenoid valve 3, the fourth solenoid valve 12 and the second solenoid valve 8, the automatic controller controls the motor 13 to start, and turn off the motor after 20 seconds of sample injection, and after the gas atmosphere is balanced, close the first solenoid valve in turn 3. The second solenoid valve 8 and the fourth solenoid valve 12, the automatic controller controls the rotation of the six-way valve 10, starts the chromatographic sample injection analysis and detection, repeats the measurement 8 times, and the detection results are shown in Table 1.

[0031] Table 1 Continuous injection of 8 ti...

Embodiment 3

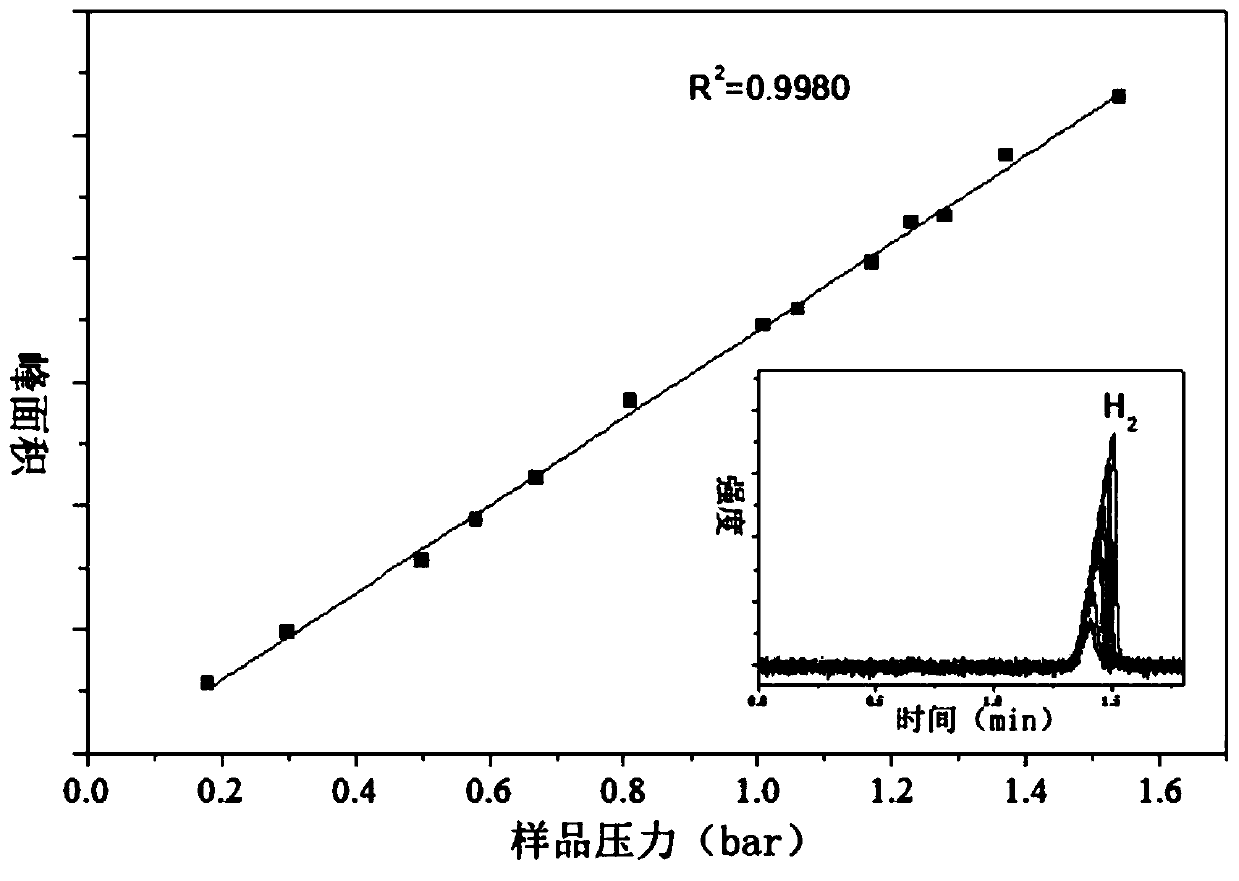

[0035] The following are the test results of positive pressure injection.

[0036] Under normal working conditions, filter 1 with H 2 After the instrument is stabilized, the first solenoid valve 3 and the fourth solenoid valve 12 are closed, and the automatic controller opens the filter 1, the third solenoid valve 14, the second solenoid valve 8, and the pressure sensor 5 and vacuum pump 15, so that the vacuum pump 15 extracts the gas in the system. After the pressure displayed by the pressure sensor 5 reaches the specified pressure, the automatic controller opens the first electromagnetic valve 3 and the filter 1, and the automatic controller controls the fine-tuning valve 2 to control the pipeline. opening, and then adjust the injection speed, the automatic controller controls the rotation of the six-way valve 10, adjusts the sample gas with different injection volumes, starts the chromatographic sample injection analysis and detection, and records the chromatographic peak r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com