Valve assembly

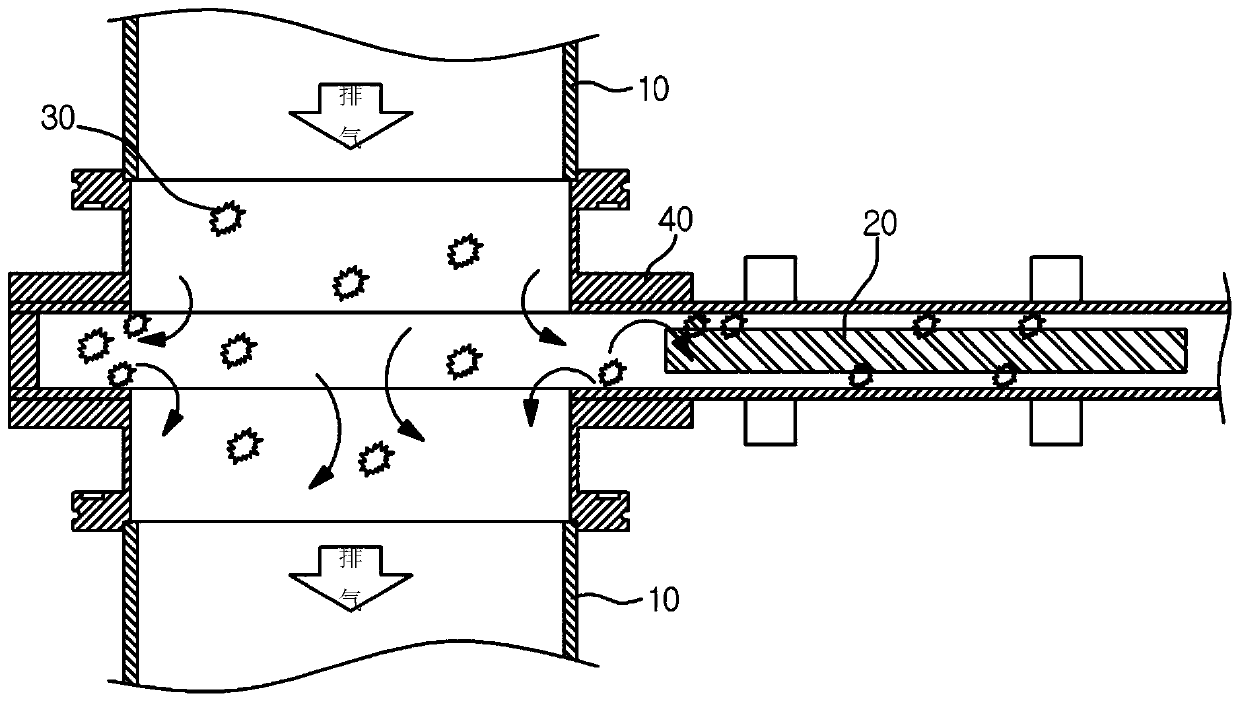

A combined body and main body technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of valve shell 40 or valve 20 corrosion drive, frequent maintenance, failure, etc., and achieve excellent exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

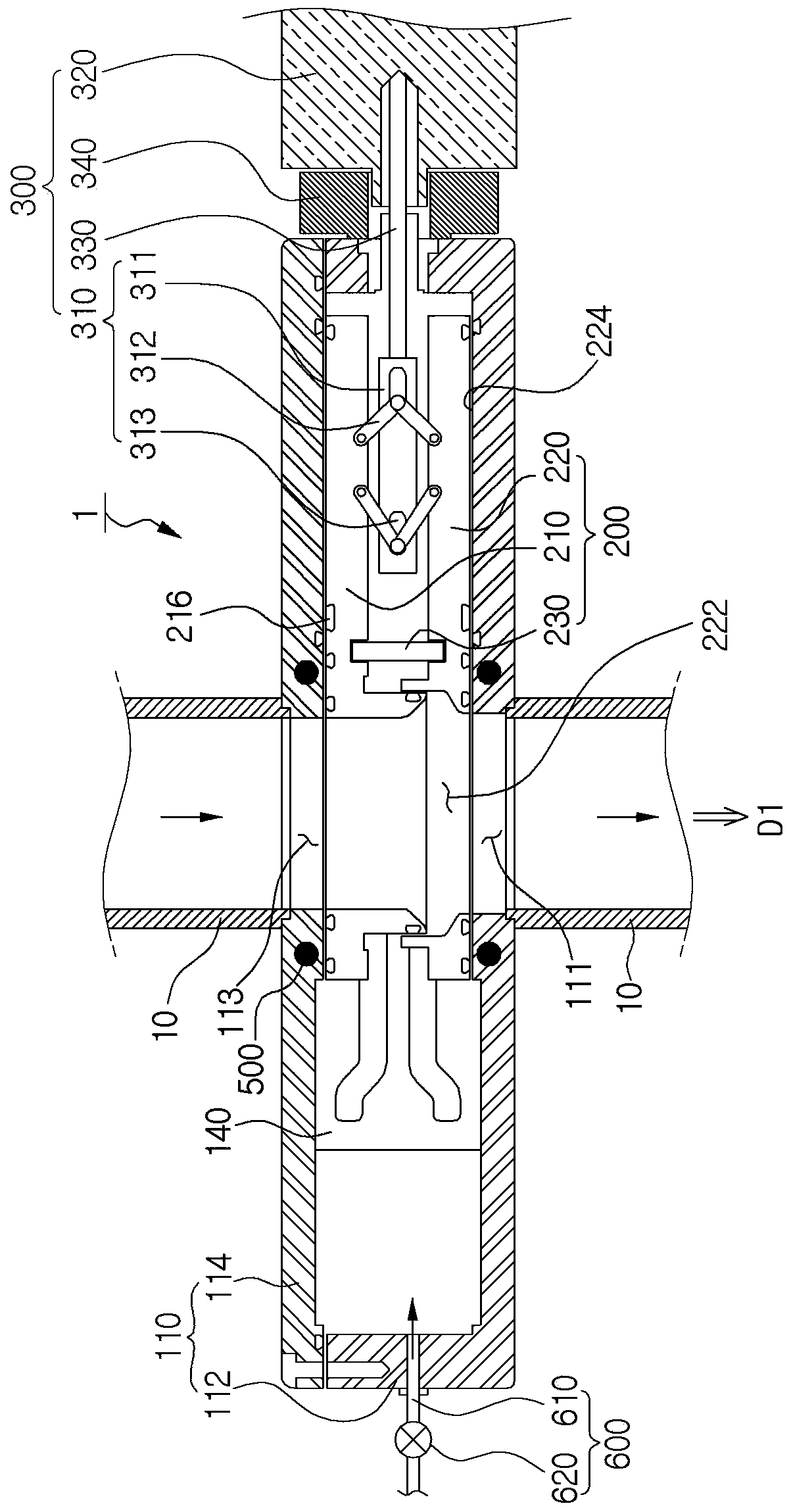

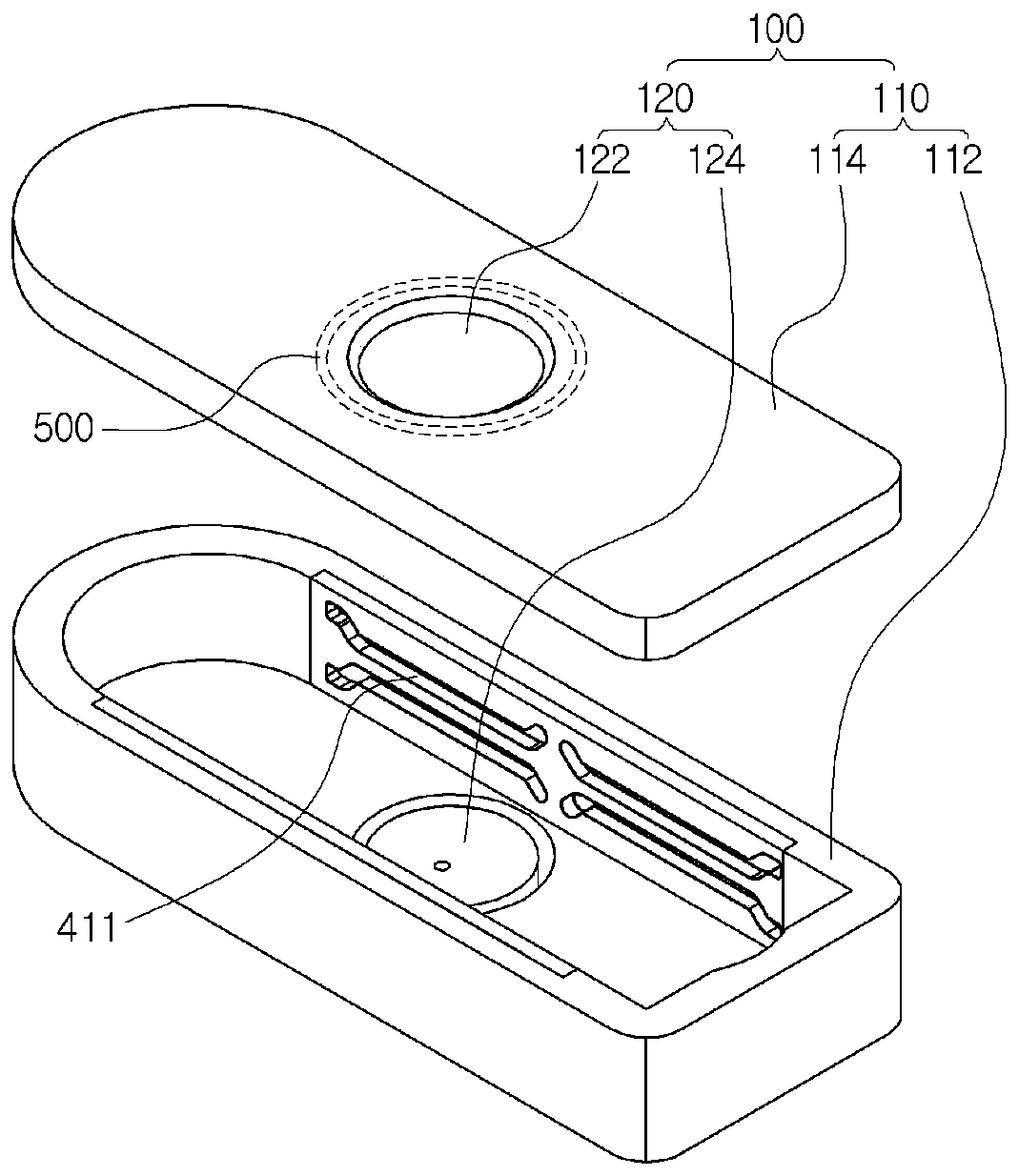

[0061] The valve assembly 1 of this embodiment also has a pressure maintaining line 710 , a housing body connection line 720 and a slow pump valve 730 . The pressure maintaining line 710 is as Figure 9 As shown, it is provided through the housing main body 110, and one end opens to the chamber-side exhaust line 10a of the exhaust lines 10, and the other end opens to the pump-side exhaust line 10b of the exhaust lines. Gas is passed through the line. In addition, the casing body connection line 720 is a gas passage line that communicates between the pressure maintaining line 710 and communicates with the inner space of the valve casing 100 . The internal pressure of the valve housing 110 and the pressure of the exhaust line 10 are always kept the same through the pressure maintaining line 710 and the housing body connection line 720 .

[0062] And, the slow pump valve 730 is as Figure 9 Shown is a member disposed on the pressure maintaining line 710 to constrain the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com