Pre-peeling equipment for preparing cow feed with hybrid paper mulberry as raw material

A cow feed and tree-making technology, which is applied to bark, animal feed, animal feed, etc., can solve the problems of reducing the economic benefits of tree bark, high labor intensity, time-consuming and labor-intensive, etc., to improve the efficiency of bark removal and the degree of automation High effect with simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

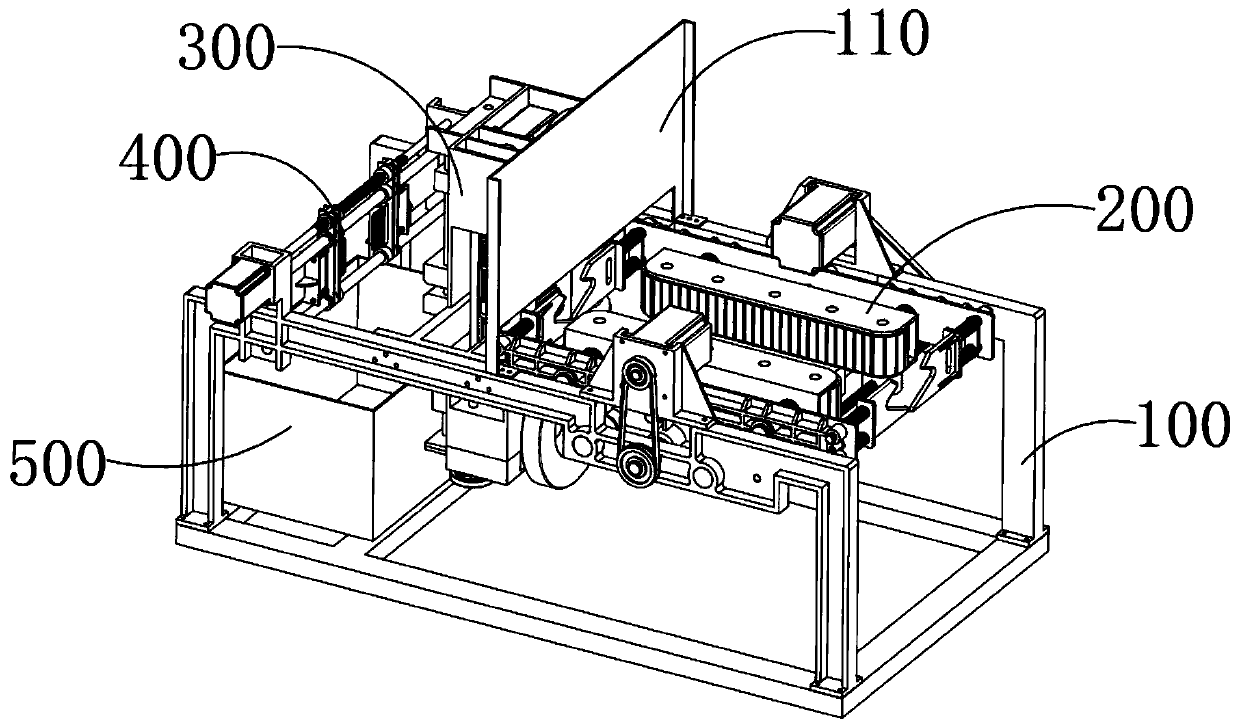

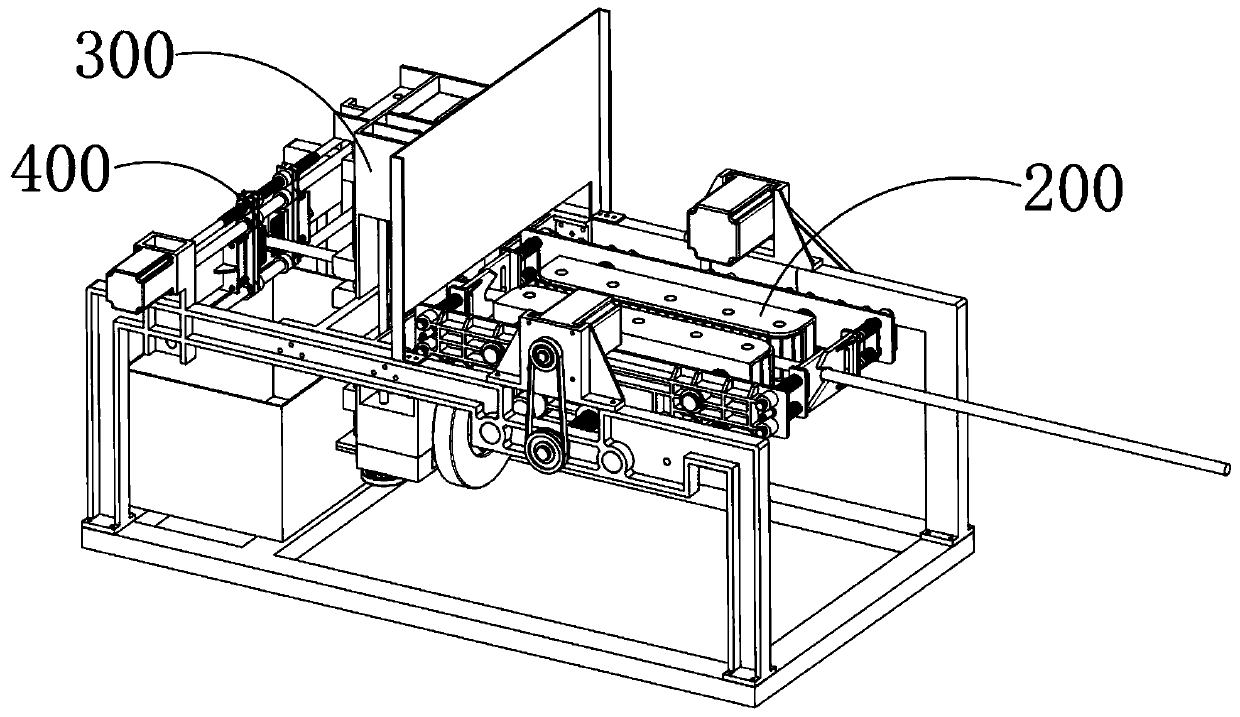

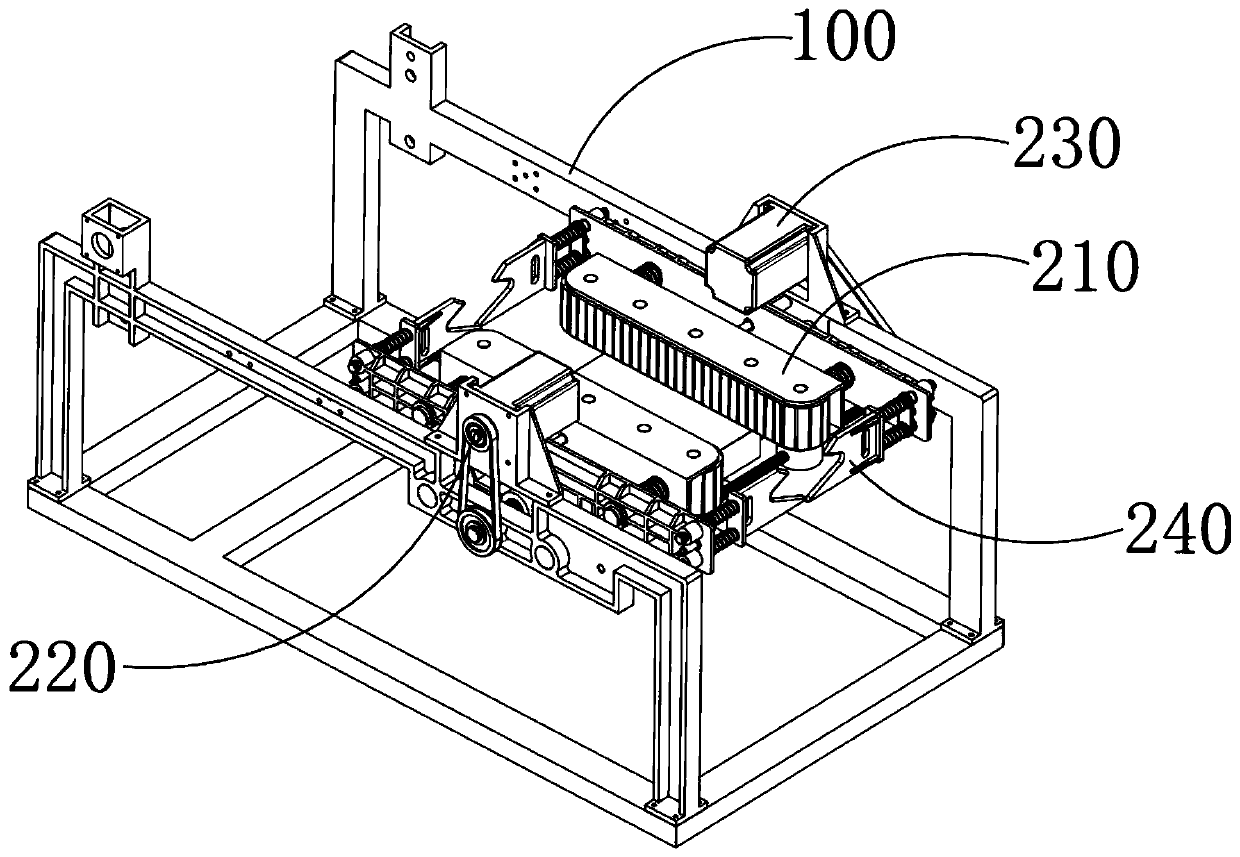

[0064] see Figure 1-34 , the pre-skinning equipment for preparing dairy cow feed with hybrid tree as raw material, which includes a rectangular hollow floor mounting frame 100, a clamping and feeding device 200, an impact separation device 300, a peeling member 400, and a collection box 500. The feeding device 200 is fixedly installed at one end of the installation frame 100 along the length direction, the peeling member 400 is fixedly installed at the other end of the installation frame 100 along the length direction, and the impact separation device 300 is fixedly installed at the middle position of the installation frame 100 along the length direction and is located in the clamp Between the holding and feeding device 200 and the peeling member 400, the collection box 500 is a rectangular box structure with an opening upward. The collecting box 500 is fixedly connected with the mounting frame 100 and is located directly below the peeling member 400. The holding and feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com