Compound beverage and preparation method thereof

A beverage and selenium-enriched technology, applied in the directions of food ingredients, the function of food ingredients, and food ingredients as taste improvers, etc., can solve the problems of weak new product development of fruit and vegetable beverages, and the inability of research and development efforts and product types to meet market demand. , to achieve the effect of improving food satiety, controlling selenium content, and improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

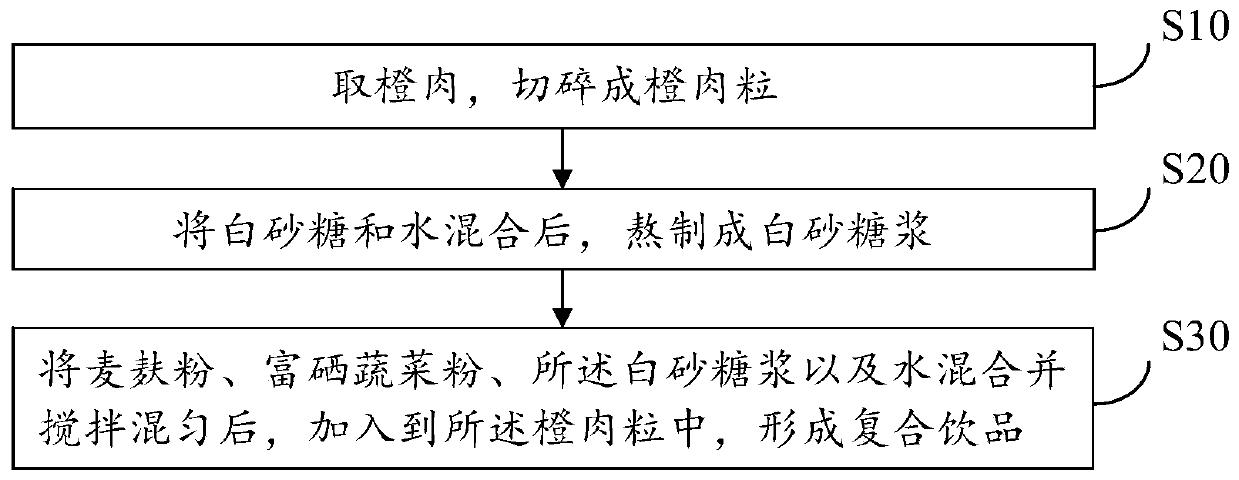

[0037] refer to figure 1 , the preparation method of described compound drink comprises the following steps:

[0038] Step S10, taking the orange meat and chopping it into orange meat pieces.

[0039]In the present embodiment, after cleaning the sweet orange, remove dirt, dust and other sundries on the surface, and then dry it with a sterilized dry cloth. The skin of the sweet orange is then removed, leaving as much pulp as possible. The peeled sweet orange pulp can be cut into orange pulp with a knife, wherein the maximum particle size of the orange pulp can be 1-1.5cm. Among them, sweet oranges are preferably oranges with good quality.

[0040] Step S20, after mixing white granulated sugar and water, boil it to make white granulated syrup.

[0041] In this embodiment, white granulated sugar and water with a mass ratio of (2.5-3.5): 1 are weighed, mixed and put into a cooking utensil for boiling until a viscous syrup is formed.

[0042] Step S30, mixing wheat bran powder...

Embodiment 1

[0054] After cleaning the orange, remove the soil, dust and other sundries on the surface, and then dry it with a sterilized dry cloth. Peel off the orange skin and remove the pulp. Cut the peeled orange pulp into orange pulp pieces with a maximum particle size of 1 to 1.5 cm, and set aside. Weigh white granulated sugar and water with a mass ratio of 3:1, mix them and put them into a cooking utensil for boiling until a viscous white granulated syrup is formed, set aside. The wheat bran is processed by an ultrafine pulverizing device to form wheat bran powder with a particle size not greater than 18 μm, which is ready for use.

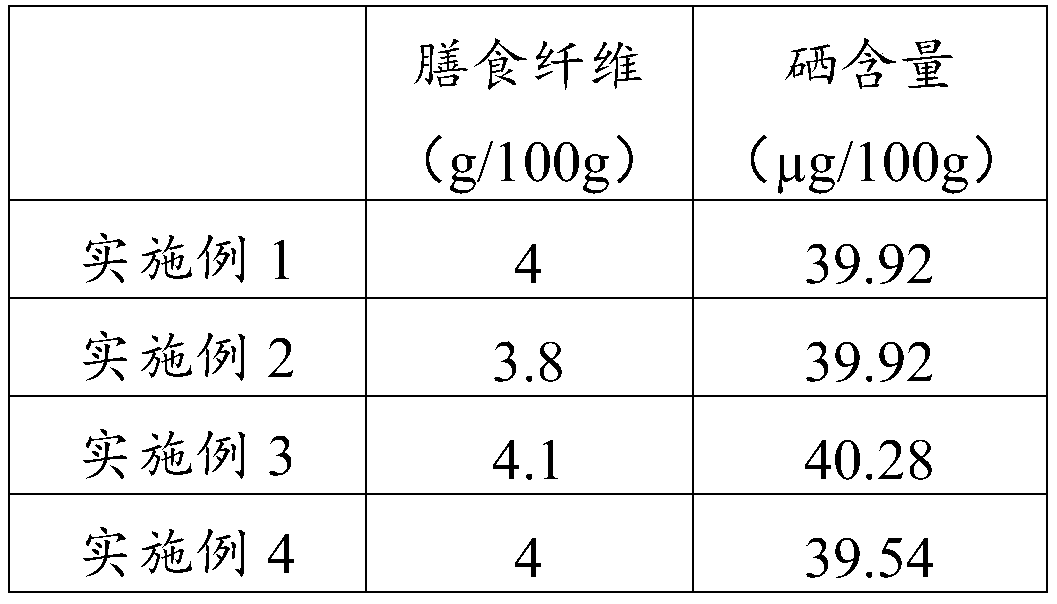

[0055] Stir and mix 25.5g wheat bran powder (particle size not greater than 18 μm), 0.061g selenium-enriched cabbage powder (selenium content is 1800ppm), 20g white sand syrup and 50g water, then add them to 175g orange meat grains, and mix well to form Compound drinks.

[0056] After the above-mentioned compound drink is packaged, it is sealed. The...

Embodiment 2

[0058] After cleaning the orange, remove the soil, dust and other sundries on the surface, and then dry it with a sterilized dry cloth. Peel off the orange skin and remove the pulp. Cut the peeled orange pulp into orange pulp pieces with a maximum particle size of 1 to 1.5 cm, and set aside. Weigh white granulated sugar and water with a mass ratio of 2.5:1, mix them and put them into a cooking utensil for boiling until a viscous white granulated syrup is formed, set aside. The wheat bran is processed by an ultrafine pulverizing device to form wheat bran powder with a particle size not greater than 18 μm, which is ready for use.

[0059] Stir and mix 24.6g wheat bran powder (particle size not greater than 18 μm), 0.058g selenium-enriched cabbage powder (selenium content is 1900ppm), 11.84g white sand syrup and 50g water, and then add them to 178g orange meat grains, mix well Form a compound drink.

[0060] After the above-mentioned compound drink is packaged, it is sealed. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com