Sandy soil recycling device after lost foam casting

A lost foam casting and sand technology, which is applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of long natural cooling time, increased production investment costs, and difficulty in solving sieve plates, so as to avoid clogging of screening holes. , The effect of improving the reuse rate and reducing the investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described below with reference to the drawings. In this process, in order to ensure the clarity and convenience of the description, we may exaggerate the width of the line or the size of the constituent elements in the illustration.

[0029] In addition, the following terms are defined based on the functions of the present invention, and may be different according to the intentions or conventions of users and operators. Therefore, these terms are defined based on the entire content of this specification.

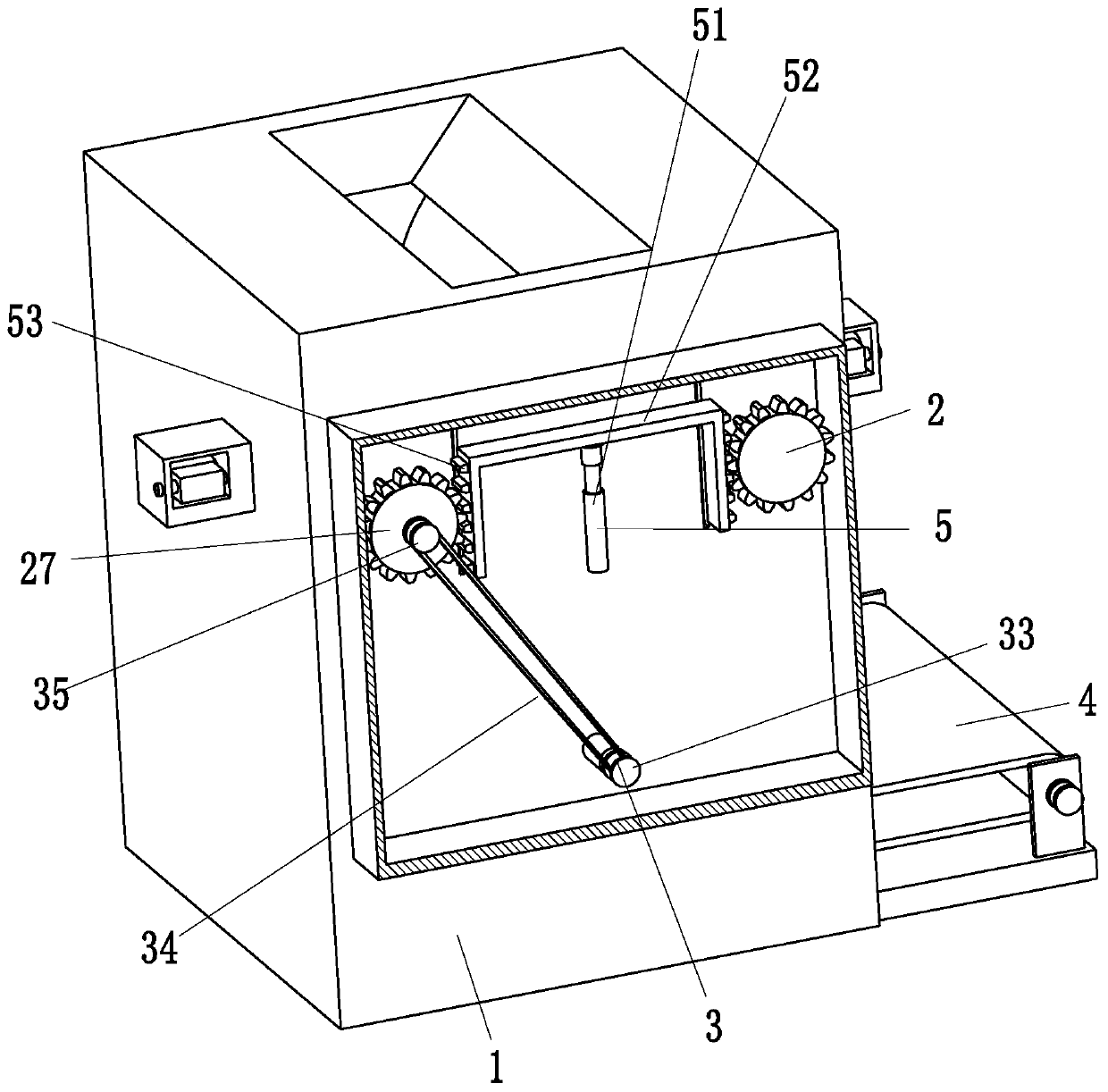

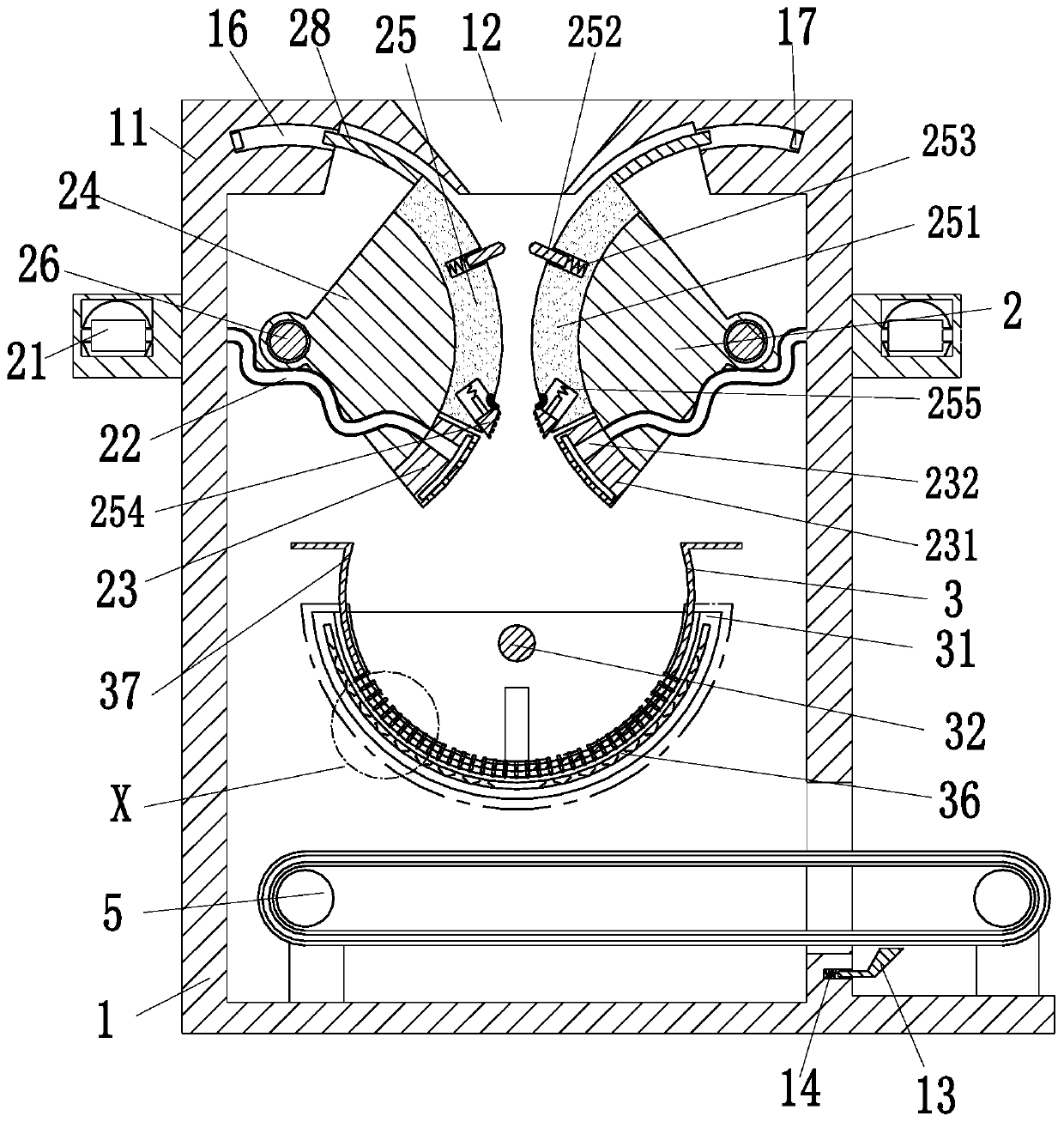

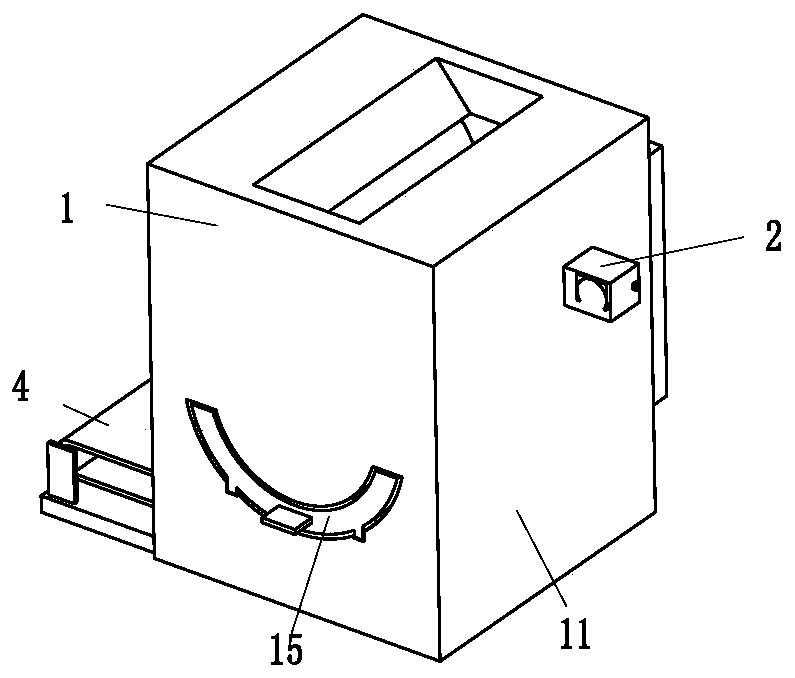

[0030] Such as Figure 1 to Figure 5 As shown, a device for recycling sand and soil after lost foam casting includes a frame body 1, two crushing and matching devices 2, a reciprocating screening device 3, a conveying line 4, and a driving device 5. The inner upper end of the frame body 1 Two crushing coordination devices 2 are installed, and the two crushing coordination devices 2 are arranged symmetrically. A reciprocati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap