Automatic nut loosening and tightening device for reaction kettle

A technology of elastic device and reactor, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome manual operation, and achieve the effects of avoiding complexity, efficient fixing and disassembly, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

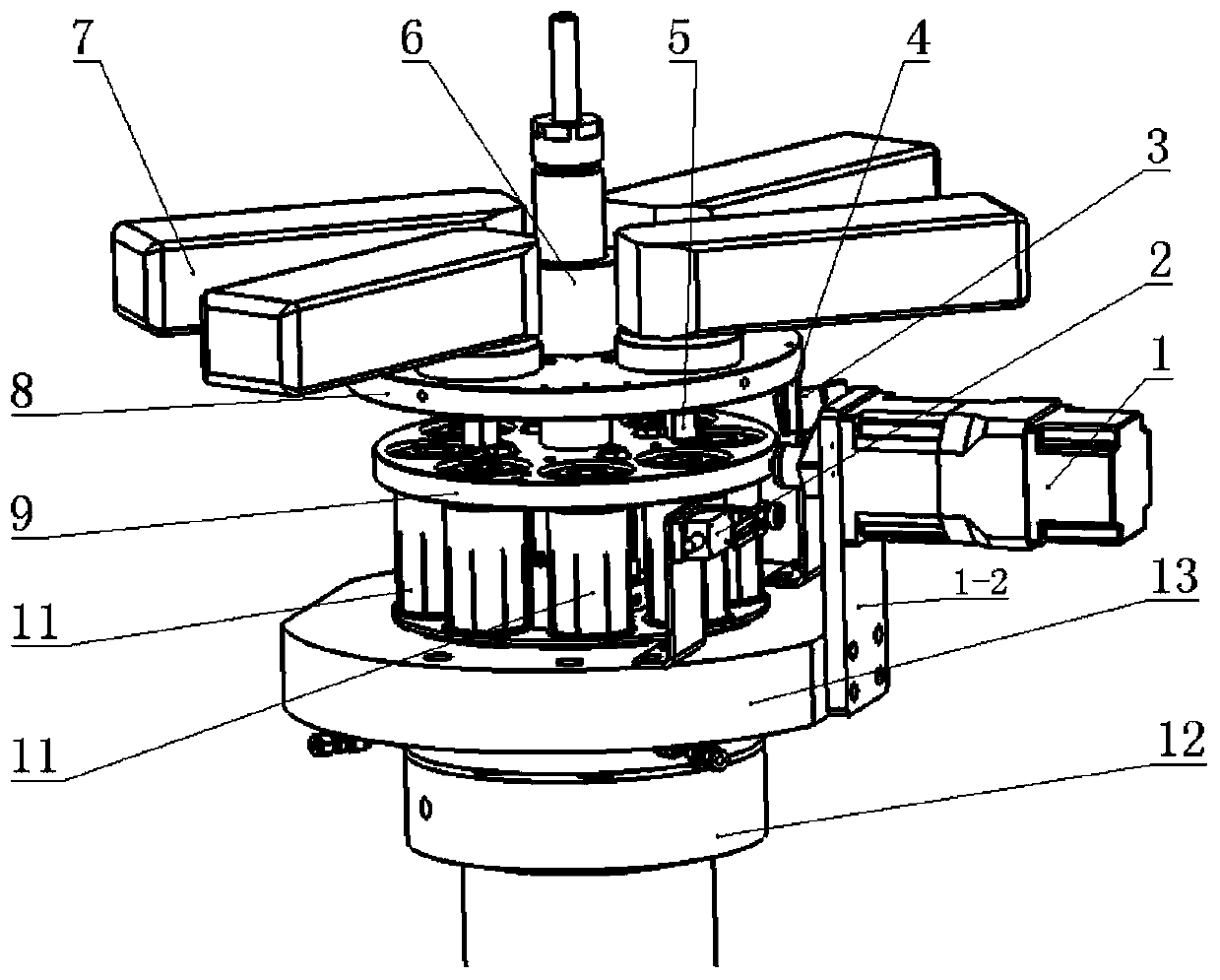

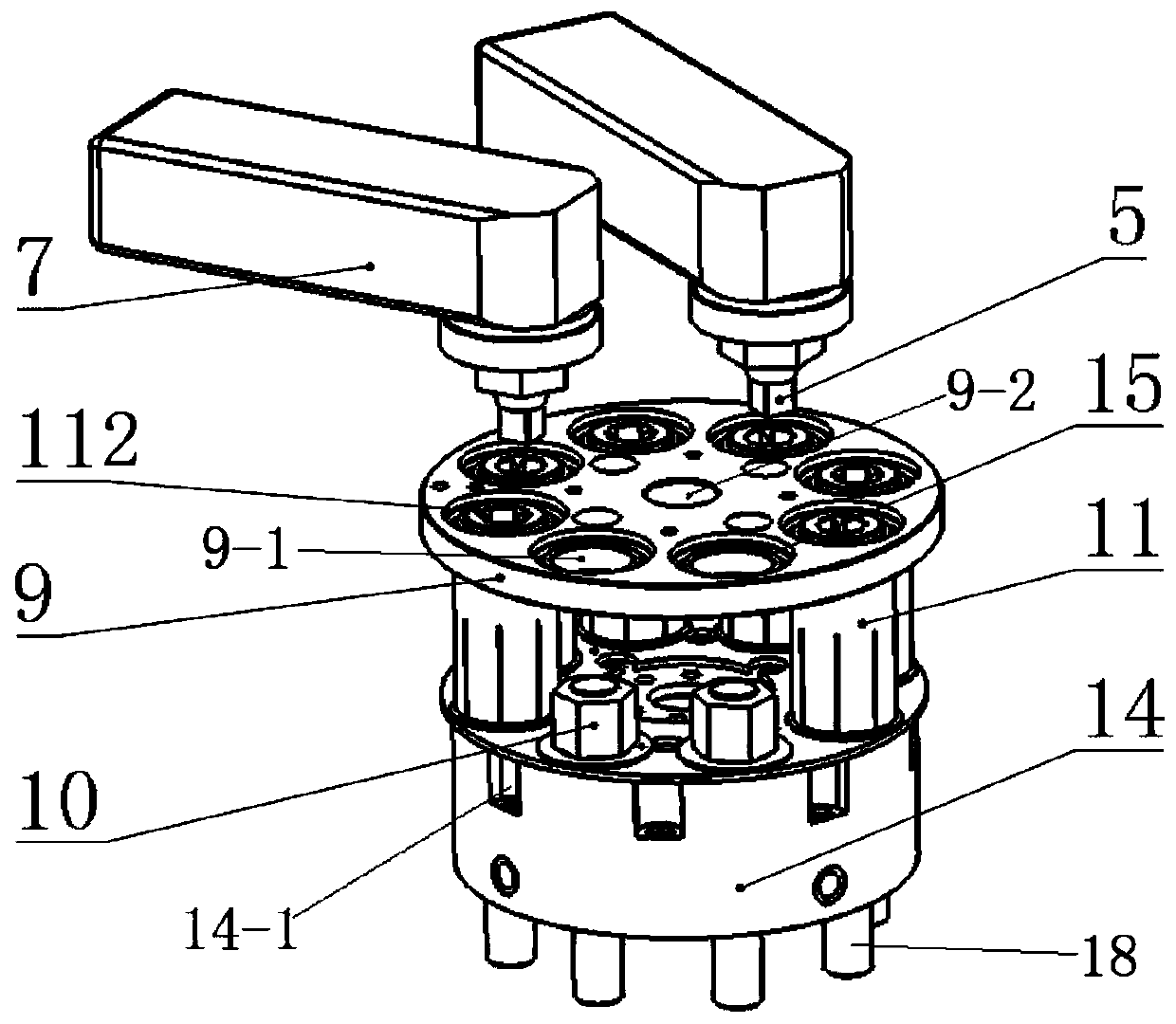

[0043] This embodiment provides an automatic nut tightening device for a reactor, which is used for fastening or loosening the nuts of a reactor for a stress corrosion test. Reactor comprises kettle body 12 and kettle cover 14, and described still cover 14 is fixed on described kettle body 12 by bolt 18 and described nut 10, and described nut 10 is made as hexagonal nut, and reactor structure is as follows: Figure 9 shown.

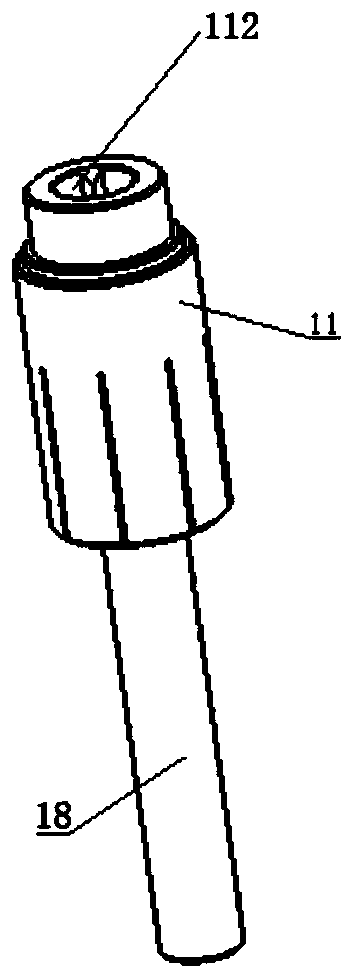

[0044] see Figure 1-8 , the nut tightening device comprises: a nut tightening part 11, a first driving mechanism 7, the quantity of the nut tightening part 11 is set to be multiple, which is equal to the number of nuts on the lid of the reactor, and the nut tightening part 11 is sleeved on the nut 10, each of the nut elastic parts 11 is matched with the nuts on the kettle cover 14 of the reaction kettle; it also includes an elastic part fixing part 9, and each of the nut elastic parts 11 is connected to the elastic part for fixing Part 9; there are mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com