Cement product mold table and method for producing cement products by using mold table

A technology for cement products and mold tables, which is applied to manufacturing tools, ceramic molding machines, molding surfaces, etc., can solve the problems of high construction site requirements, poor reuse effect, and large area occupied, and achieves easy maintenance, simple structure, The effect of reducing occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

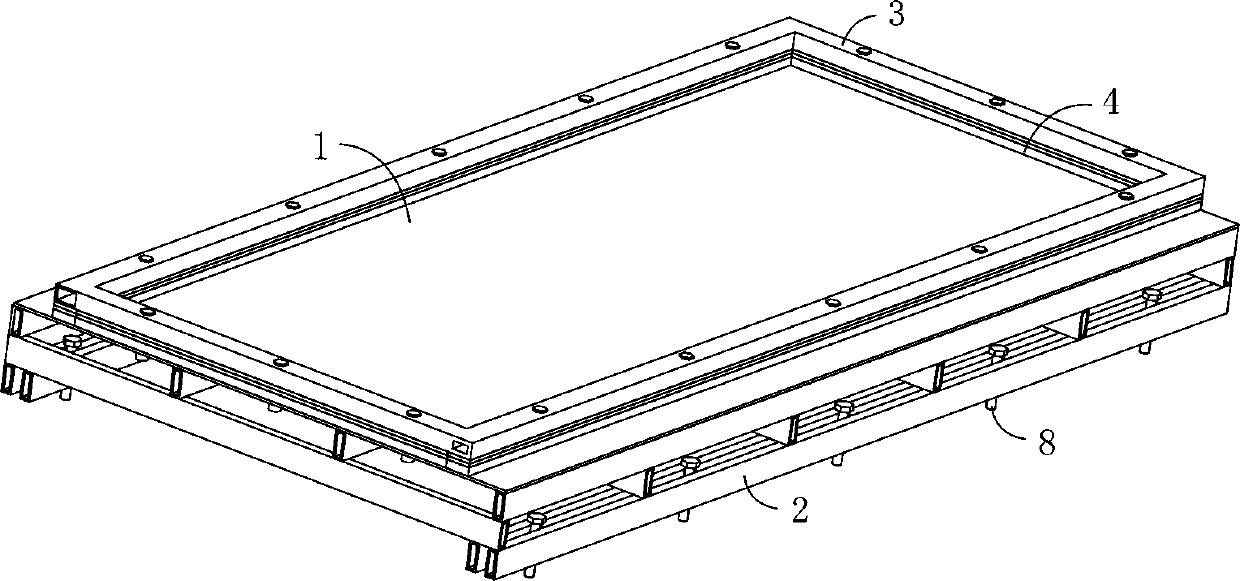

[0038] Embodiment one, such as Figure 1-Figure 12 As shown, this embodiment is the optimal embodiment, a mold table for cement products, including a mold table 1, the bottom of the mold table 1 is fixedly provided with a formwork that can adapt to compression deformation, and the mold table 1 The upper end surface is provided with a shape frame for forming cement products.

[0039] In this implementation, the frame includes a lower frame 4 fixedly installed on the upper surface of the formwork plate, and the front and rear sides of the lower frame keep a distance from the edge of the formwork plate, thereby forming a stacking area 1.1.

[0040] In this embodiment, the shape frame further includes an upper shape frame 3 having the same shape as the lower shape frame, and the upper shape frame is detachably clamped above the lower shape frame through the mounting part 7 .

[0041] The mounting part is a block clamp fixedly installed on the formwork plate, and the block clamp p...

Embodiment 2

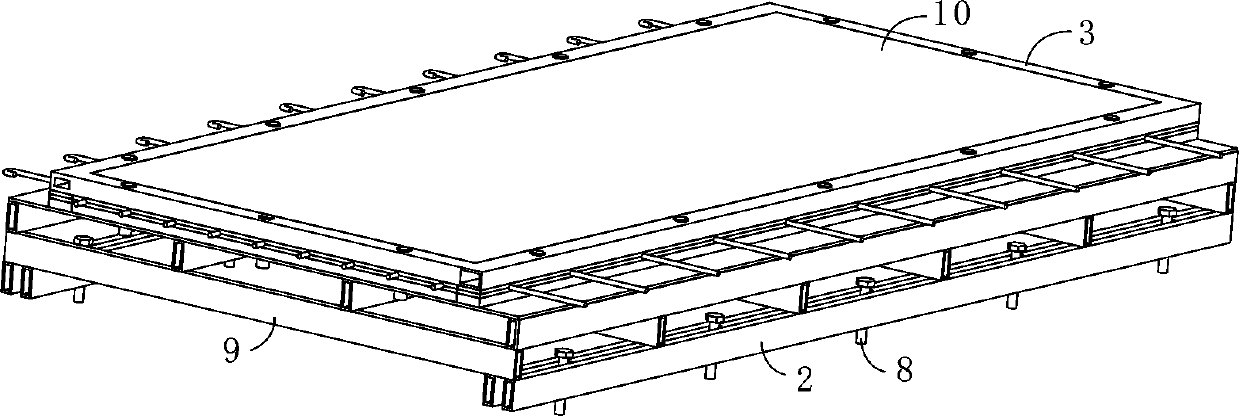

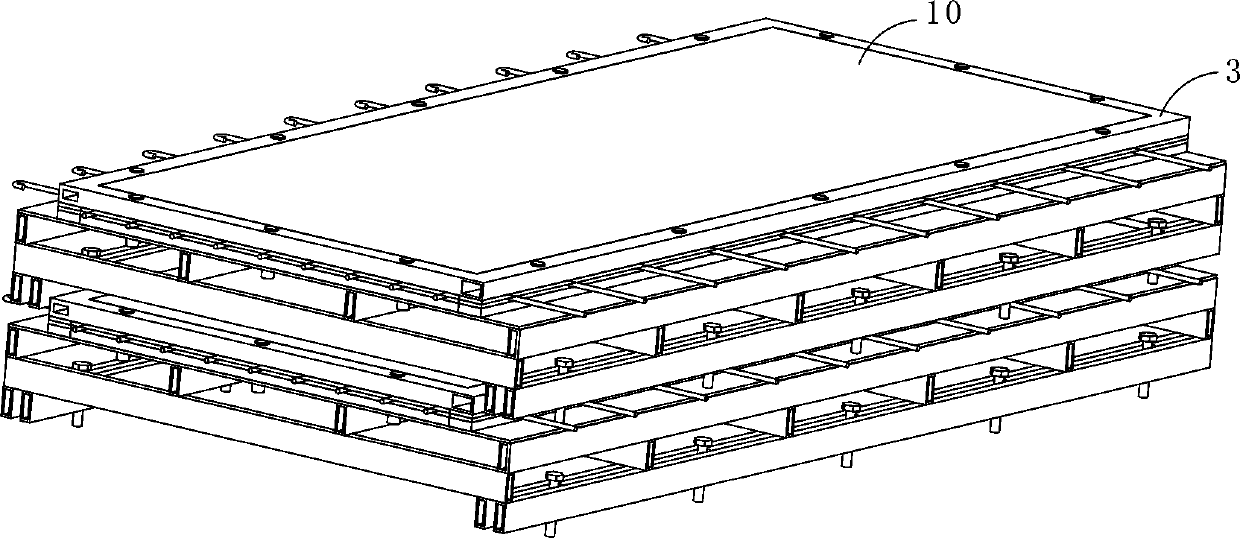

[0056] Embodiment two: if Figure 5-Figure 7 As shown, a mold platform for cement products includes a mold platform 1, the bottom of the mold platform 1 is fixedly provided with a formwork capable of adapting to compression deformation, and the upper end surface of the mold platform is provided with a mold for molding cement products. shaped frame.

[0057] In this implementation, the frame includes a lower frame 4 fixedly mounted on the upper surface of the formwork plate, and the front and rear sides of the lower frame keep a distance from the edge of the formwork plate, thereby forming a stacking area 1.1.

[0058] A soft anti-spill pad is fixedly connected to the upper end surface of the lower frame.

[0059] In this implementation, the front and rear parts of the bottom of the formwork are respectively provided with several height-adjusting foot pads for adapting to compression deformation or uneven ground.

[0060] In this implementation, the front and rear parts of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com