Seamless welding device and method for plastic floors

A technology of seamless welding and plastic flooring, applied in metal processing and other fields, can solve problems such as low operating efficiency and high work intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

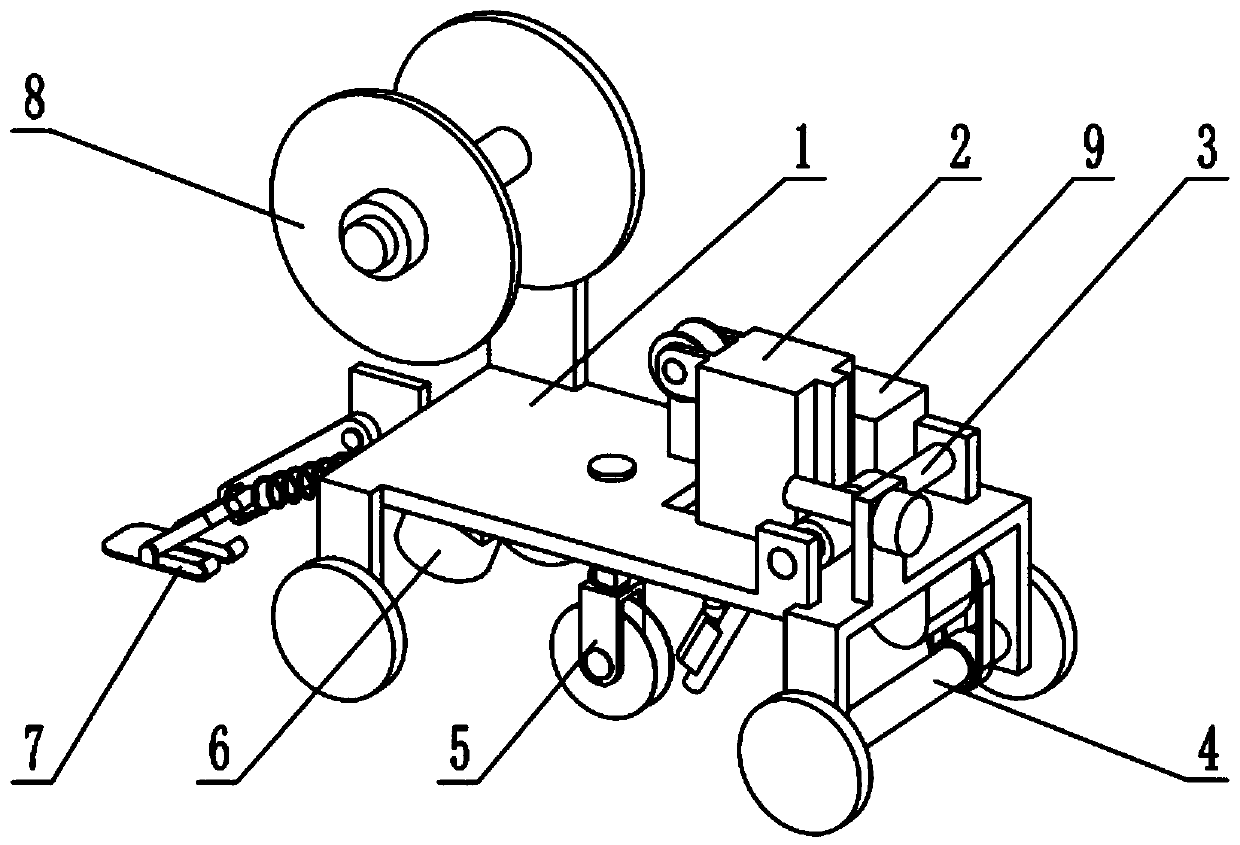

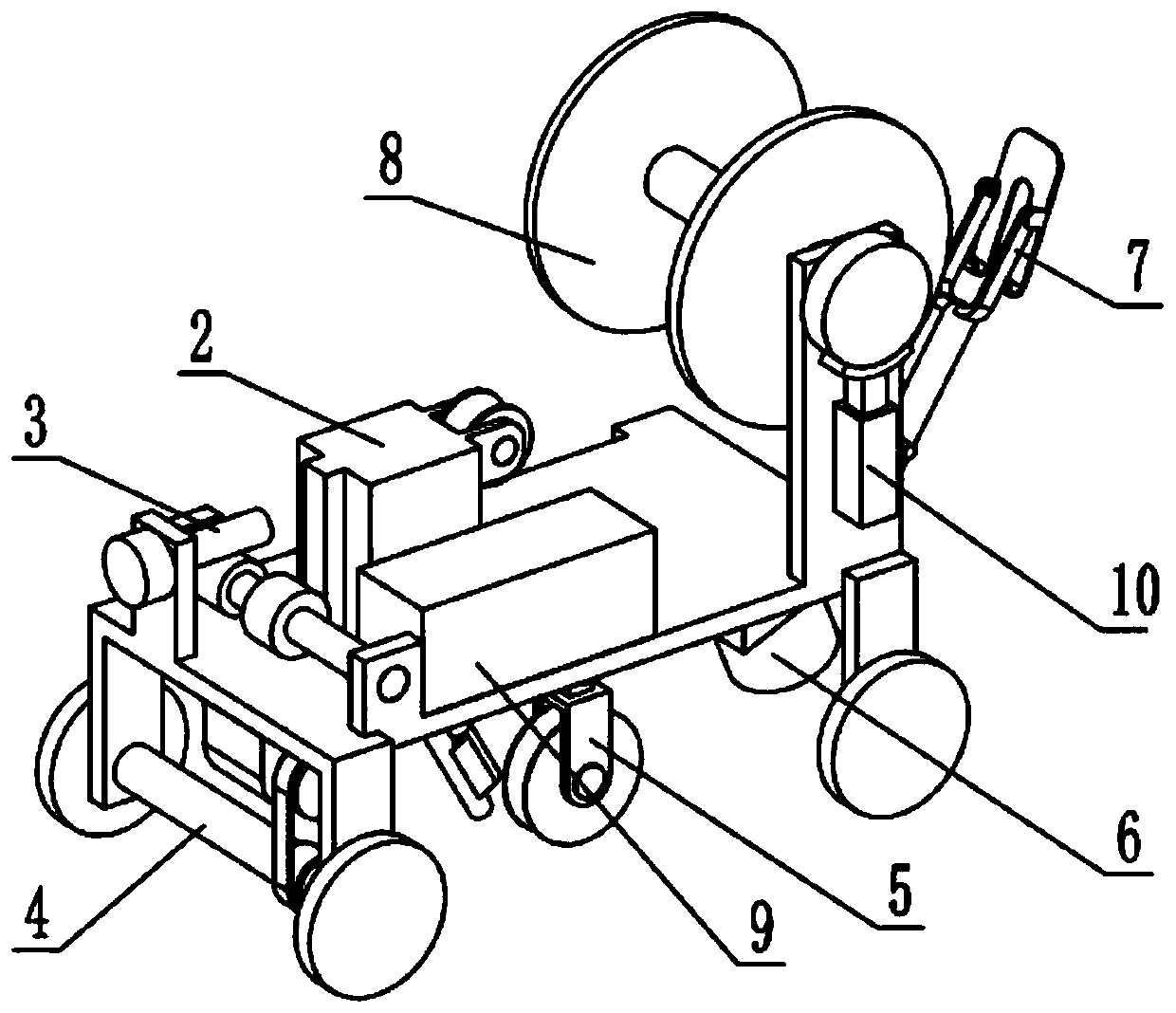

[0034] Such as Figure 1-11As shown, a plastic floor seamless welding device includes a moving frame 1, a welding part 2, a lifting control mechanism 3, a moving mechanism 4, an electrode pressing mechanism 5, a fan 6, a cutter mechanism 7, an electrode installation mechanism 8, a power supply 9 and a brake mechanism 10, the welding part 2 is slidably connected to the moving frame 1, the lifting control mechanism 3 is rotatably connected to the moving frame 1 and connected to the welding part 2, and the moving mechanism 4 is connected to The front end of the mobile frame 1, the electrode pressing mechanism 5 is slidably connected to the mobile frame 1, the electrode pressing mechanism 5 is located directly behind the weldment 2, and the fan 6 is fixedly connected to the lower end of the mobile frame 1. 6 is located directly behind the electrode pressing mechanism 5, the cutter mechanism 7 is connected to the rear end of the mobile frame 1, the cutter mechanism 7 is located dir...

specific Embodiment approach 2

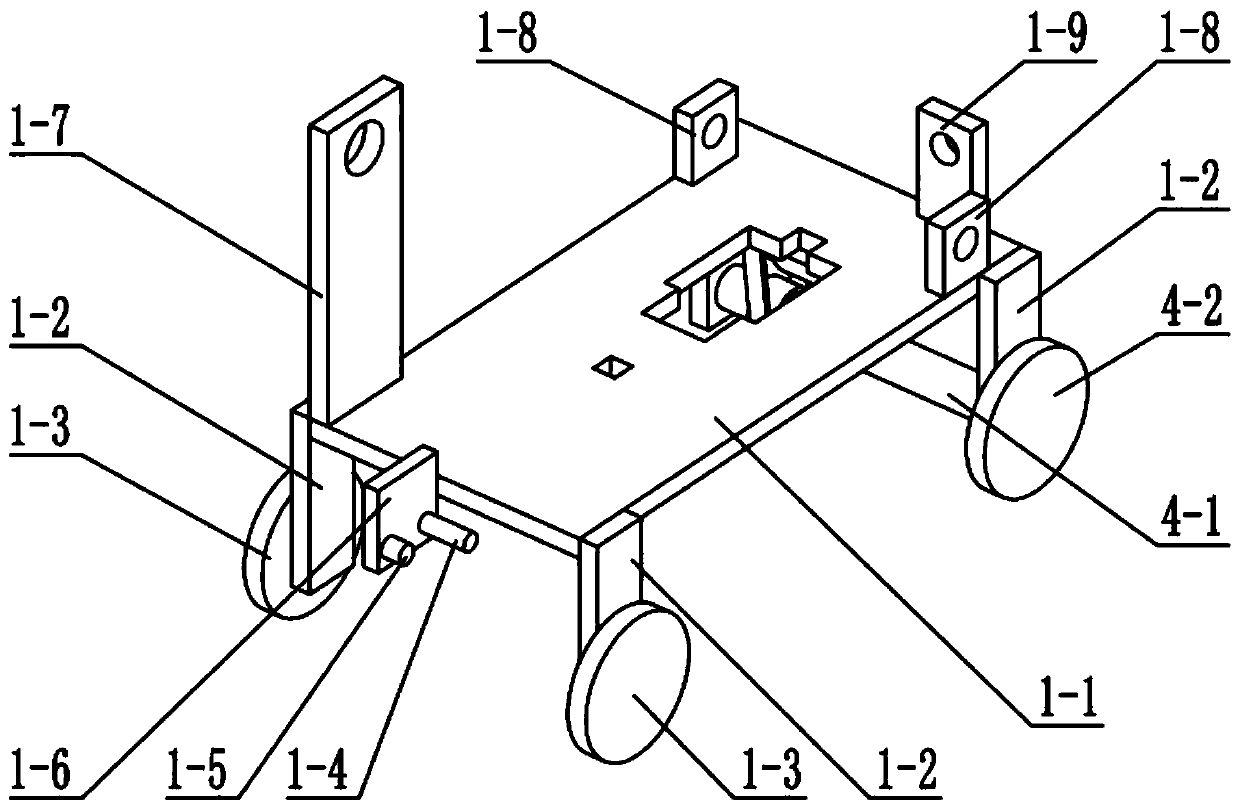

[0037] Such as Figure 1-11 As shown, the mobile frame 1 includes a main board 1-1, a leg plate 1-2, a moving wheel I 1-3, a tension spring connection pin 1-4, a fixed pin 1-5, a fixed plate 1-6, and a support plate 1-7. The mounting plate 1-8 and the mounting seat 1-9, the four corners of the main board 1-1 are welded and fixed with the outrigger plate 1-2, and the two outrigger plates 1-2 at the rear end are connected by bearing rotation There are movable wheels Ⅰ1-3, fixed plate 1-6 is welded and fixed on the rear end of main board 1-1, extension spring connecting pin 1-4 and fixed pin 1-5 are welded and fixed on fixed plate 1-6, and supporting plate 1 -7 is welded and fixed on the upper end surface of the mainboard 1-1 rear end, and the mounting plate 1-8 is provided with two, and the two mounting plates 1-8 are all welded and fixed on the upper end surface of the front end of the mainboard 1-1, and the mounting seat 1- 9 is welded and fixed on the front end of the mainbo...

specific Embodiment approach 3

[0040] Such as Figure 1-11 As shown, the weldment 2 includes a welding torch 2-1, a preheating pipe 2-2, a connecting plate 2-3, a guide wheel 2-4 and a rack 2-5, and the preheating pipe 2-2 is fixedly connected to the welding torch On the torch head of 2-1, two connecting plates 2-3 are provided, and the two connecting plates 2-3 are all fixedly connected to the rear end of the welding torch 2-1, and the guide wheel 2-4 is rotatably connected to the two connecting plates 2 Between -3, the rack 2-5 is fixedly connected to the front end of the welding torch 2-1, the welding torch 2-1 is slidably connected to the main board 1-1, and the welding torch 2-1 is connected to the power supply 9 through a wire and a switch;

[0041] The guide wheel 2-4 on the welding torch 2-1 can guide the electrode that falls off on the electrode roll in the preheating pipe 2-2 in a regular manner, so as to improve the preheating efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com