Pad type roller skin structure of medium-pressure roller press

A technology of roll skin and tiles, which is applied in the field of tile-type roll skin structure of medium-pressure roller presses, can solve problems such as the inability to eliminate the misalignment of the extrusion surface of the roll, the shape and position tolerance of the keyway, and the inability to effectively prevent loosening, etc., to achieve improved Effects of product quality and performance, control processing accuracy, and easy processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

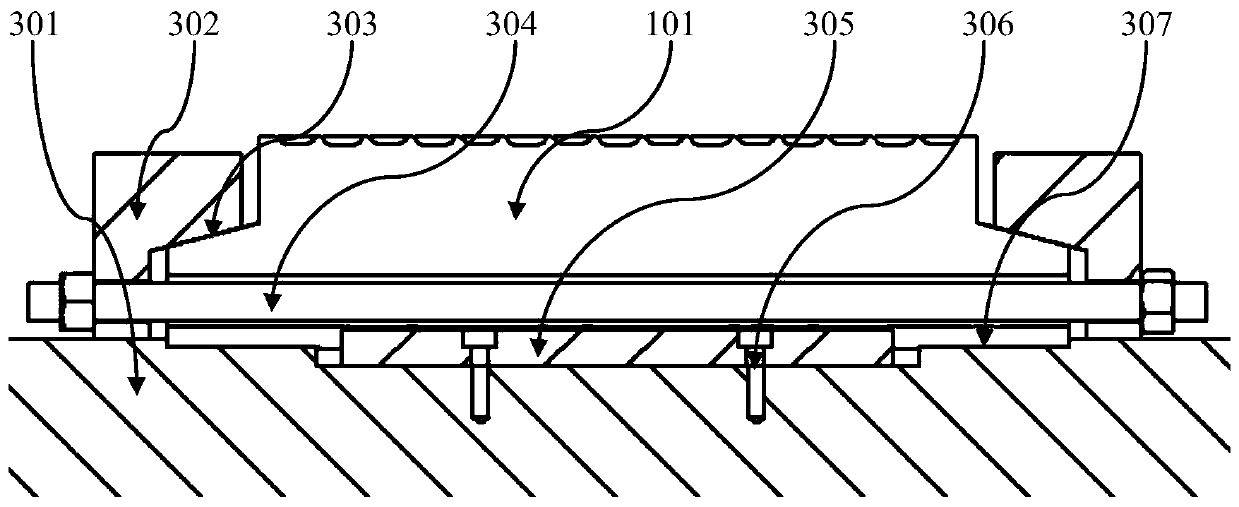

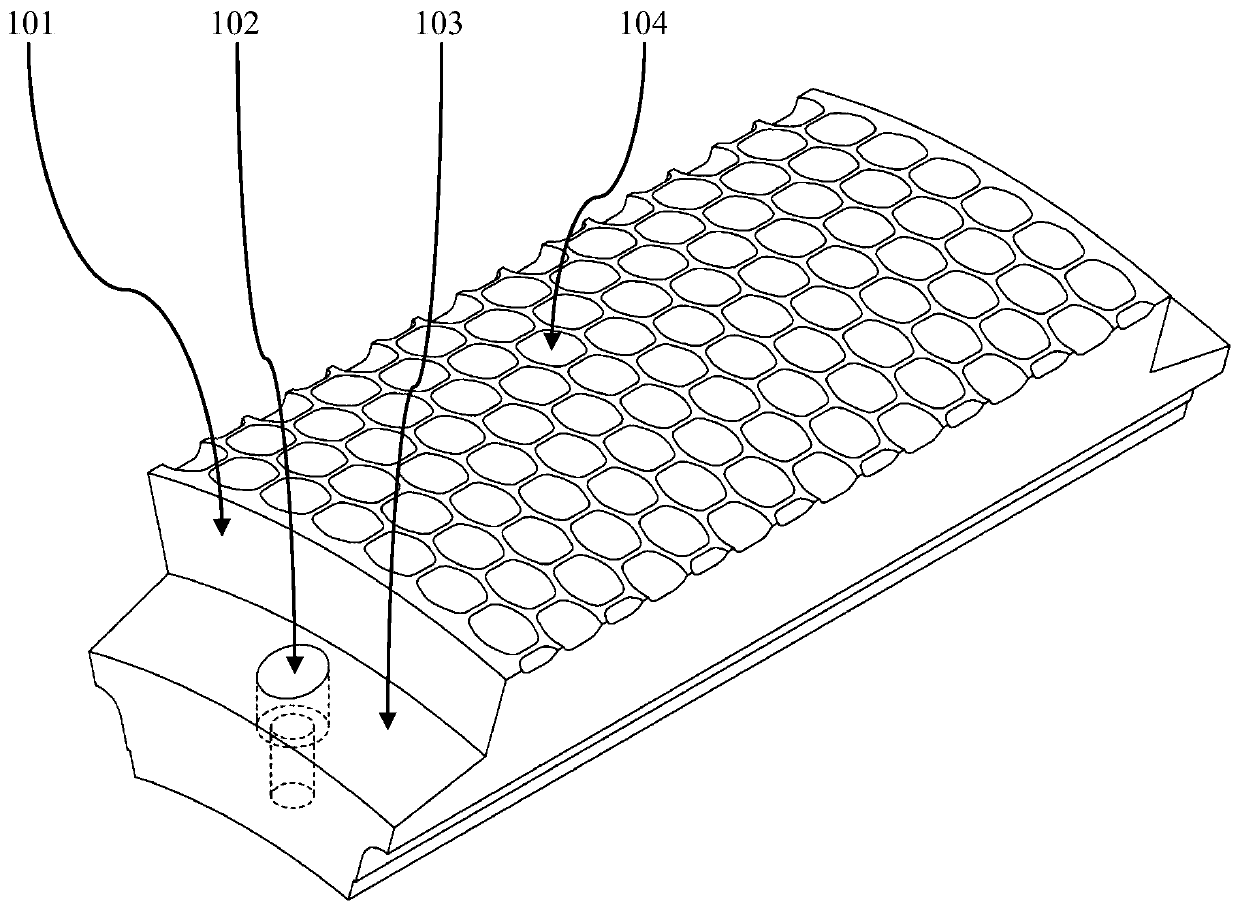

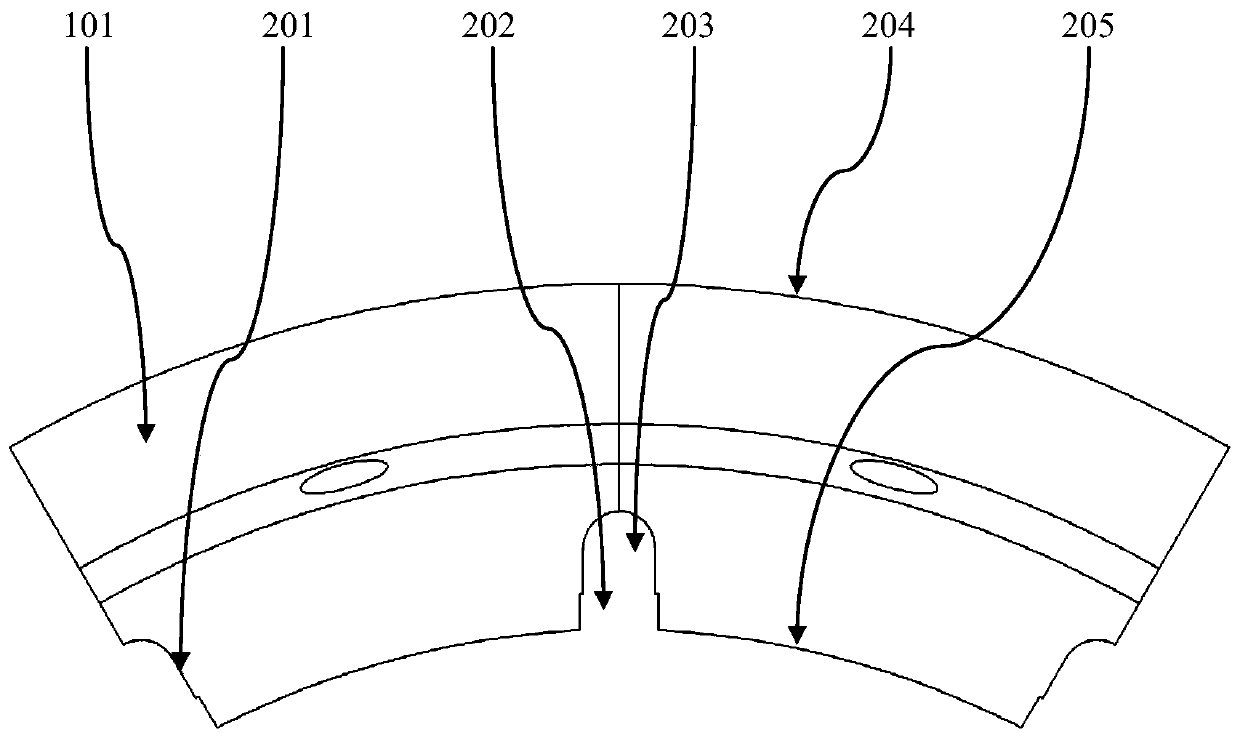

[0023] When the axial length of the outer arc surface 204 of the tile-type roller skin 101 is 380 mm to 400 mm, the axial length of the inner arc surface 205 of the tile-type roller skin 101 should be 475 mm to 495 mm. The diameter of the arc surface 205 should be 580-600 mm, the diameter of the outer arc surface 204 of the tile-type roller skin 101 should be 800-825 mm, and the angle between the tapered inner circular surface 303 of the roller skin locking ring 302 and the axis should be The angle between the wedge-shaped flange 103 tapered generatrix and the axis at both ends of the tile-type roller skin 101 should be 15±1 degrees, and the angle formed by the stepped grooves 201 on both sides of the tile-type roller skin 101 should be 30±0.5 degrees, 12 tile-type roller skins 101 should be assembled into a complete ring. At this time, the tile-type roller skin structure of the medium-pressure roller press is easy to manufacture and assemble, and has the best performance and e...

Embodiment 2

[0025] When the axial length of the outer arc surface 204 of the tile-type roller skin 101 is 305 mm to 325 mm, the axial length of the inner arc surface 205 of the tile-type roller skin 101 should be 400 mm to 420 mm. The diameter of the arc surface 205 should be 550-570 mm, the diameter of the outer arc surface 204 of the tile-type roller skin 101 should be 790-815 mm, and the angle between the tapered inner circular surface 303 of the roller skin locking ring 302 and the axis should be The angle between the wedge-shaped flange 103 tapered generatrix and the axis at both ends of the tile-type roller skin 101 should be 15±1 degrees, and the angle formed by the stepped grooves 201 on both sides of the tile-type roller skin 101 should be 30±0.5 degrees, 12 tile-type roller skins 101 should be assembled into a complete ring. At this time, the tile-type roller skin structure of the medium-pressure roller press is easy to manufacture and assemble, and has the best performance and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com