Metal plate continuous printing and drying system

A printing drying and metal plate technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problems of cumbersome operation, high labor intensity, trouble, etc., and achieve continuous printing drying, low labor intensity and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the drawings.

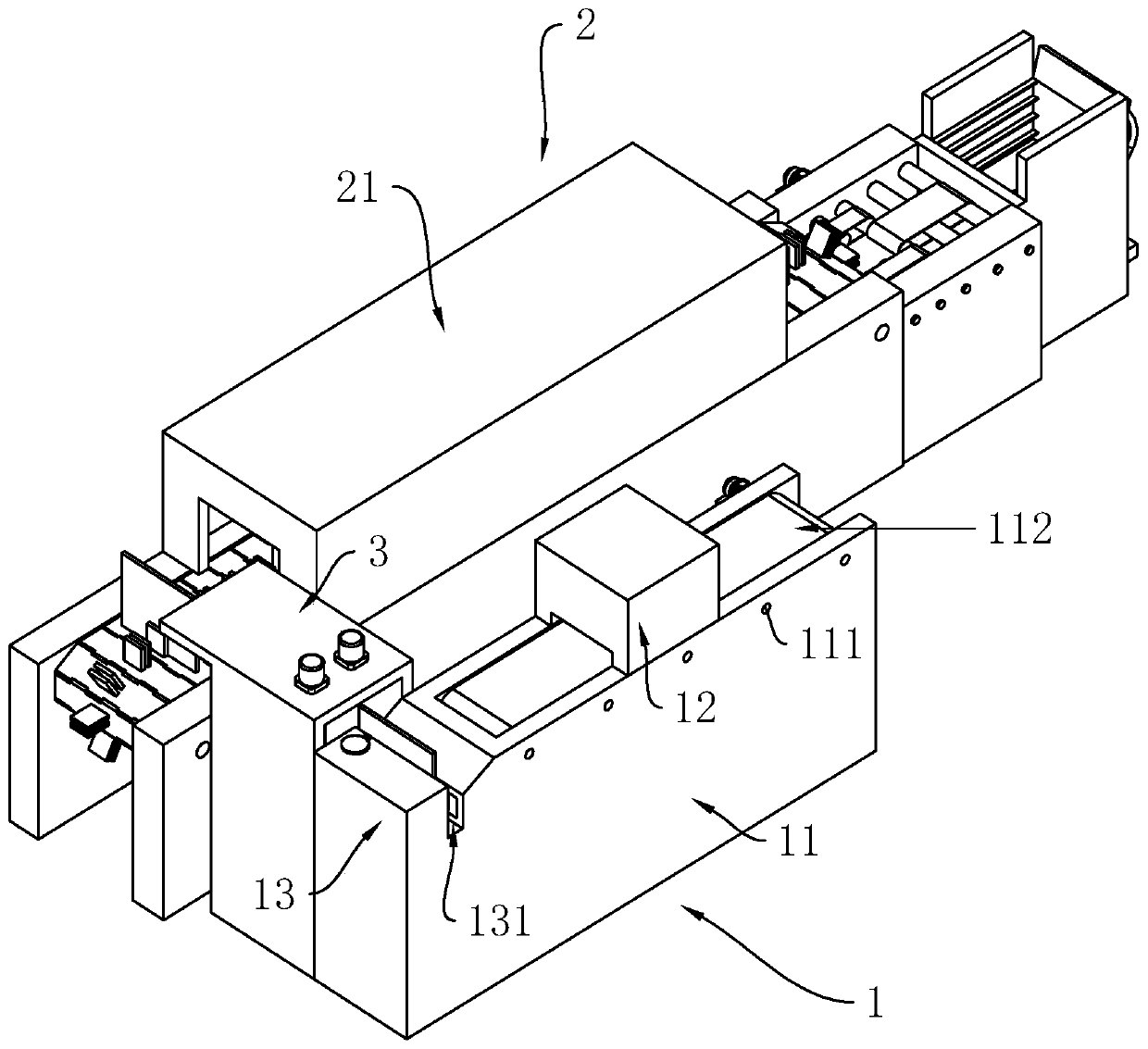

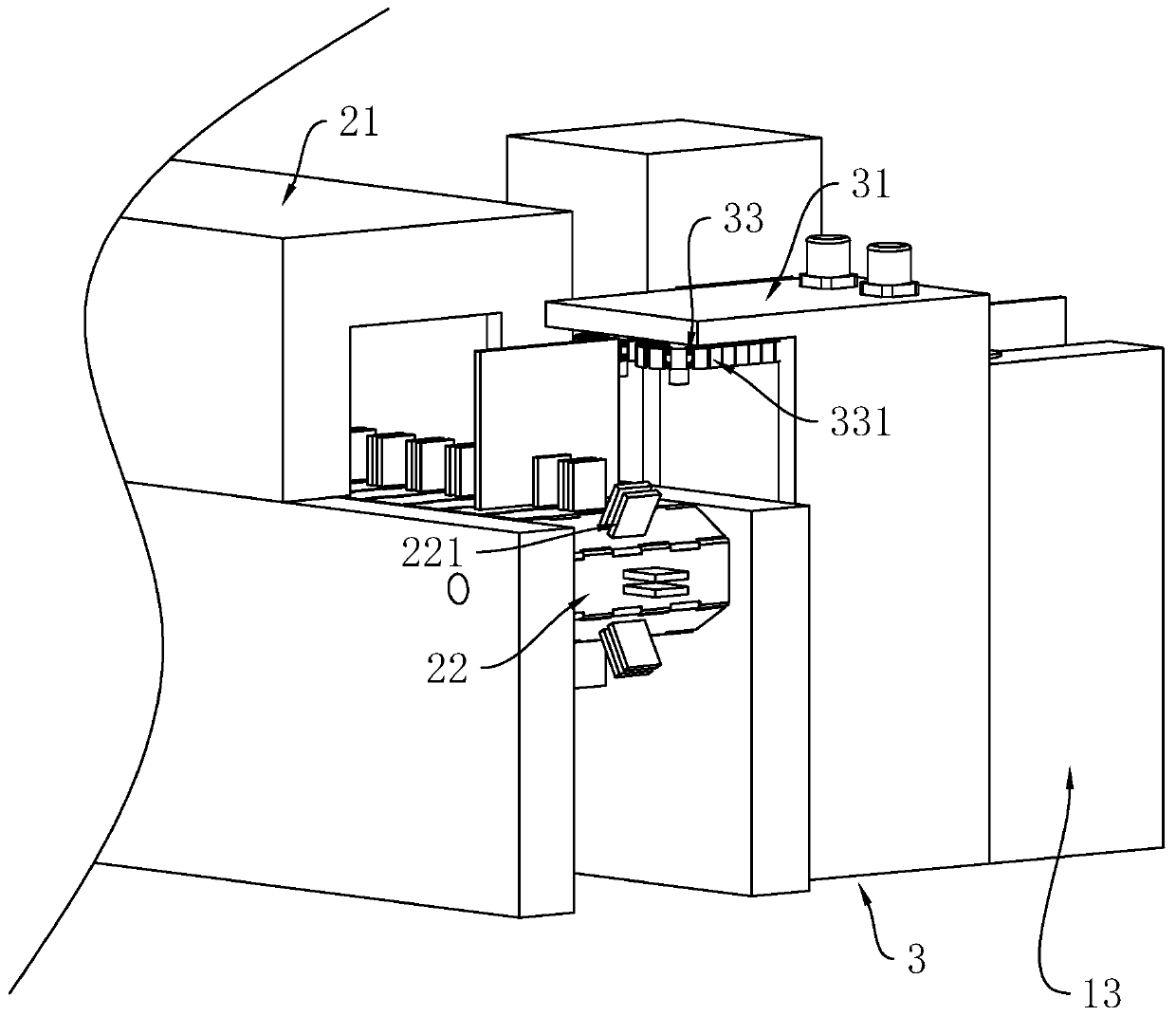

[0037] Reference figure 1 , Is a metal sheet continuous printing and drying system disclosed in the present invention, including a printing device 1, a drying device 2 and a transfer device 3.

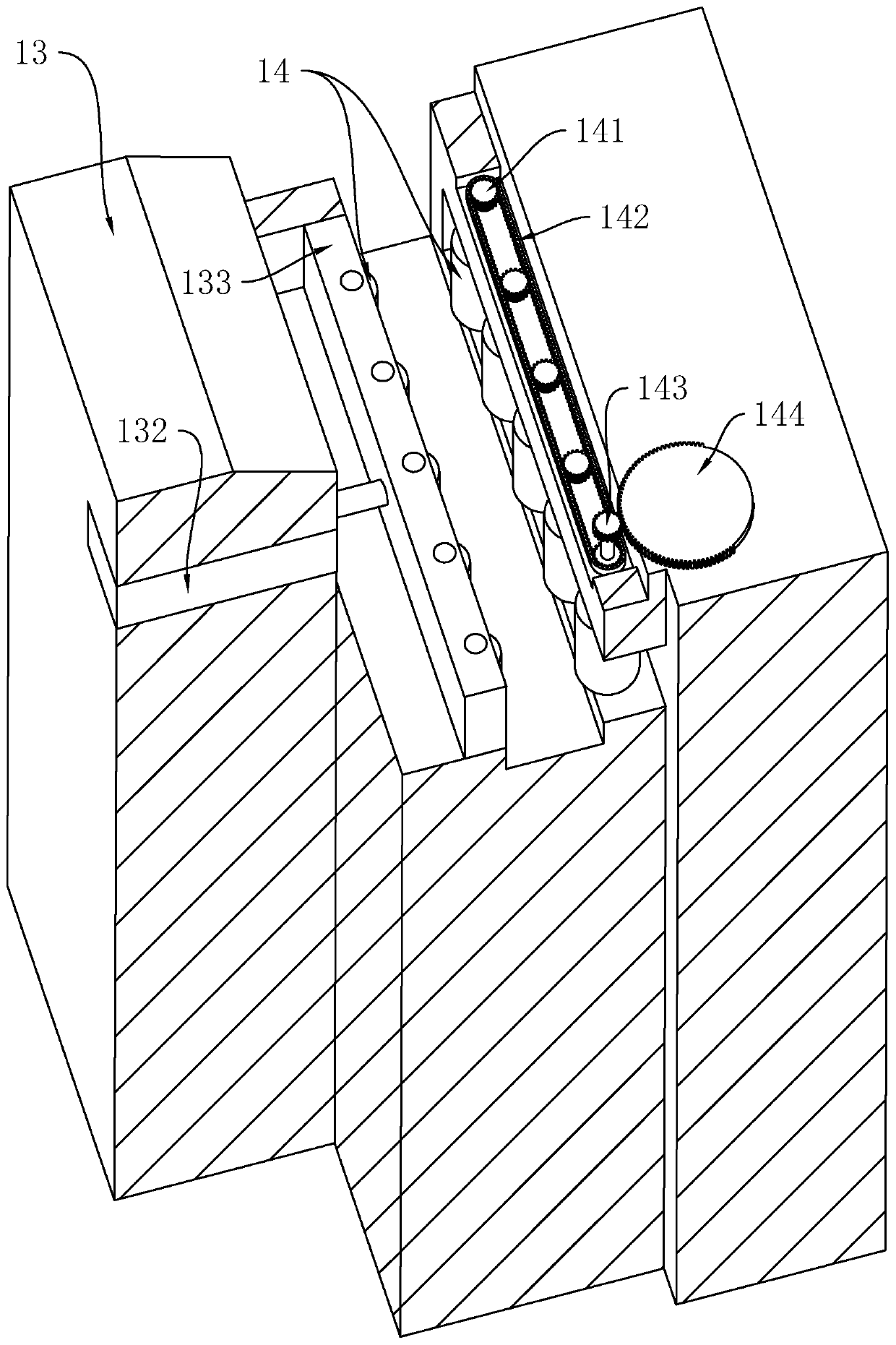

[0038] The printing equipment 1 includes a conveying table 11, the upper side of the conveying table 11 is rotatably connected with a plurality of rotating rollers 111, the plurality of rotating rollers 111 are sleeved with a feeding belt 112, and the conveying table 11 is fixedly connected to the end of the feeding belt 112. There is a servo servo motor, and the output shaft of the servo motor is fixedly connected to the end of a rotating roller 111. The upper side of the middle of the conveying table 11 is also fixedly connected with a printing device 12 (here is the prior art and will not be repeated here), the discharge end of the conveying table 11 is fixedly connected with a disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com