Match production equipment

A technology for production equipment and matches, which is applied in the field of match production equipment, can solve problems such as failure of match stem insertion, waste of raw materials, easy breakage of match stems, etc., and achieve the effects of improving utilization rate, improving production efficiency, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

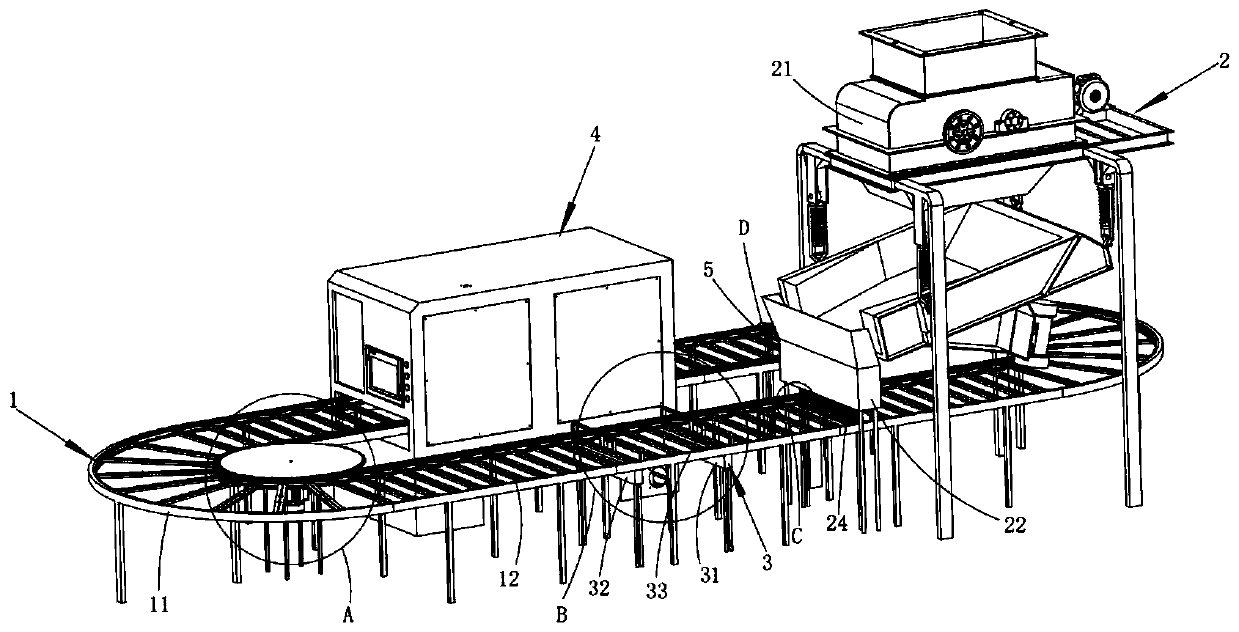

[0045] Such as figure 1 Shown, a kind of match production equipment comprises:

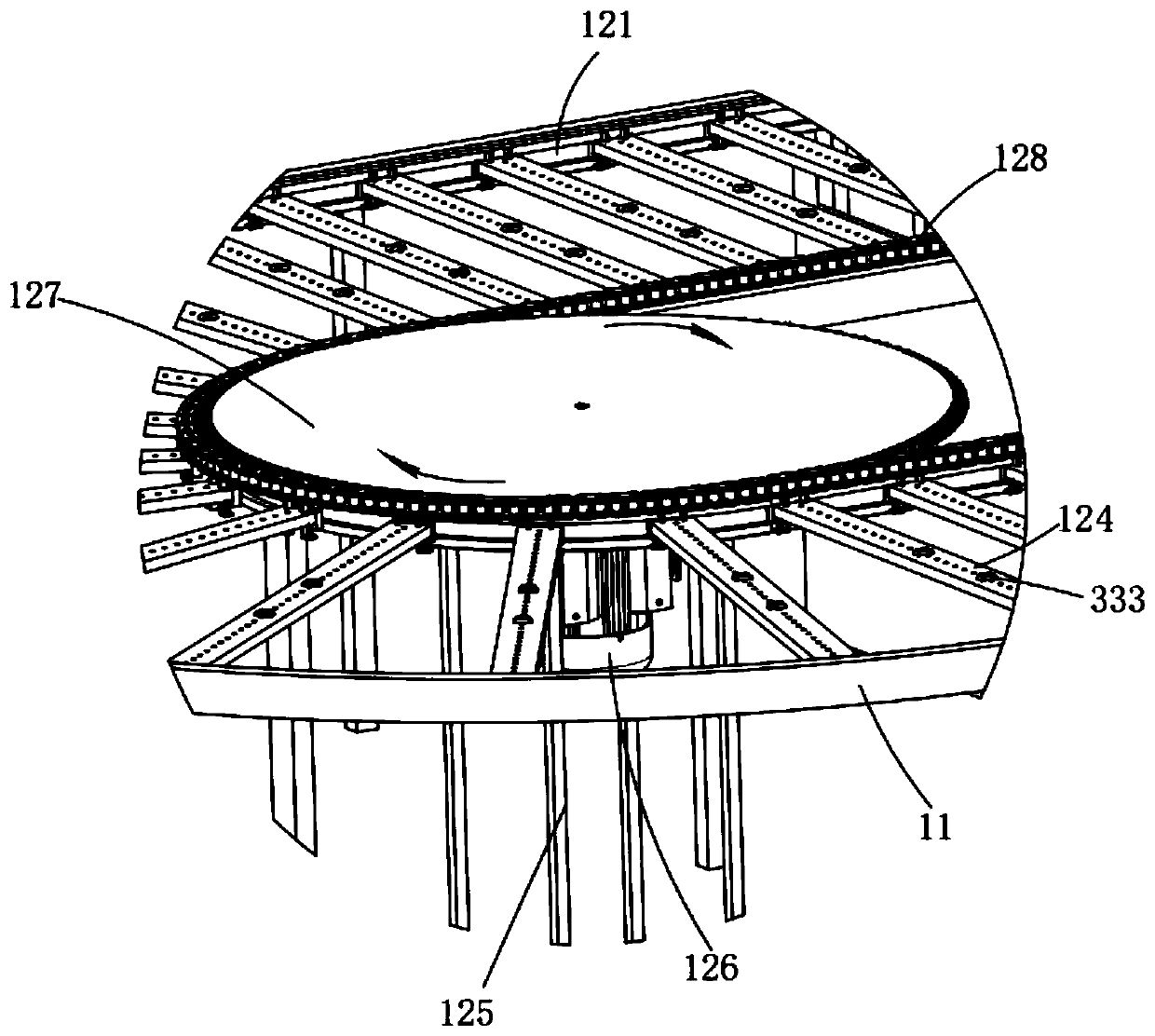

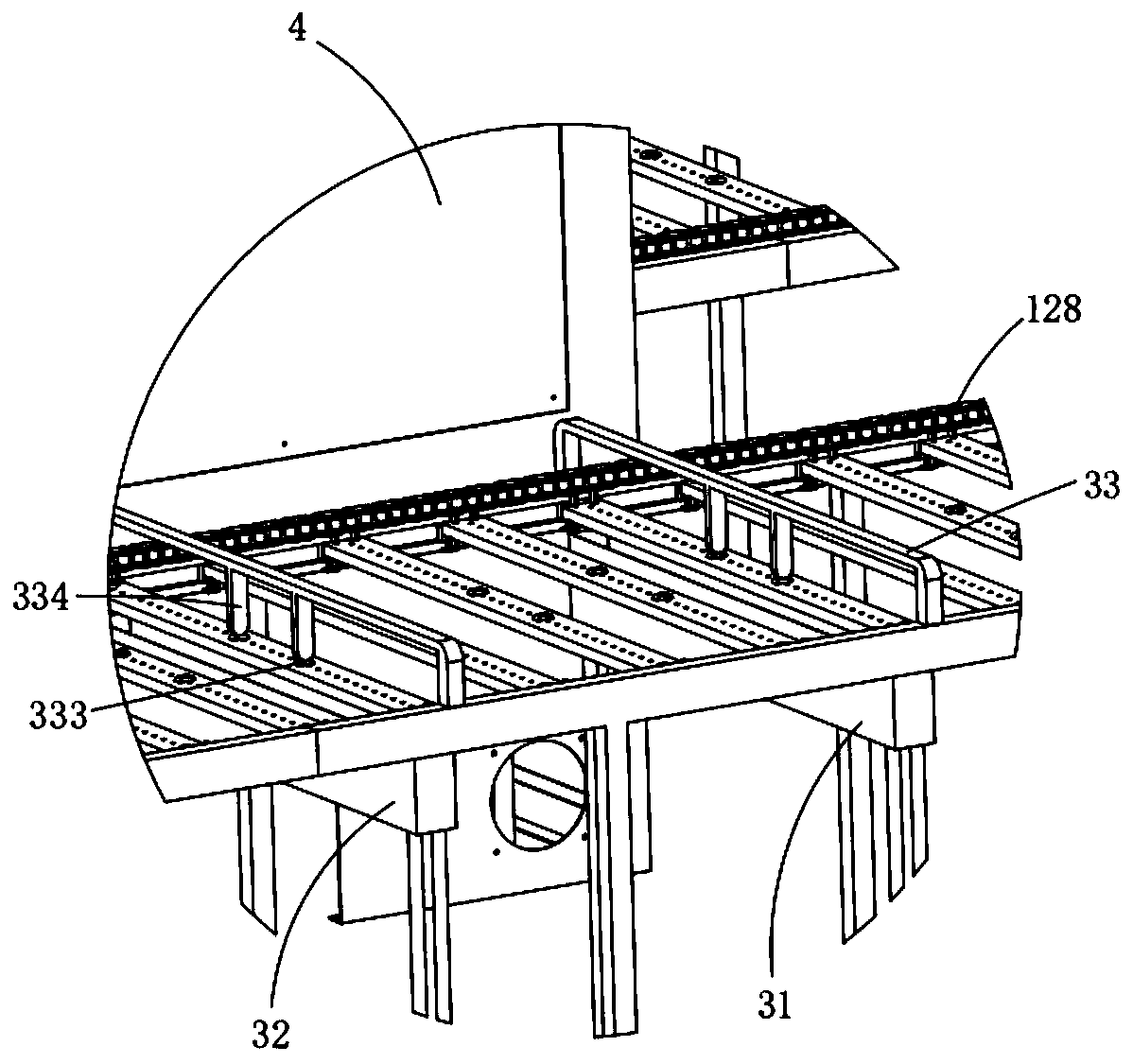

[0046] Transportation device 1, described transportation device 1 comprises mounting frame 11, moving assembly 12 and fixed assembly 13, and described mounting frame 11 is arranged in ring; Several described moving assemblies 12 move along described mounting frame 11 path, and described moving The components 12 can be slid up and down; several fixed components 13 are distributed in an array along the length direction of the moving component 12, and the fixed components 13 include a material receiving port 131 and a splint 132, and the material receiving port 131 runs through the moving component 12. A pair of splints 132 are slidably arranged along the longitudinal direction of the material receiving port 131, and the two are symmetrically arranged on both sides of the material receiving port 131 in the longitudinal direction;

[0047] Feeding device 2, described feeding device 2 comprises feeder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com