A liquid-phase titanium-based composite catalyst, its preparation method and its application in the preparation of polyester compounds

A technology of composite catalyst and titanium compound, which is applied in the field of liquid-phase titanium-based composite catalyst to prepare polyester compounds, can solve the problems of low catalytic efficiency and achieve fast catalytic rate, low carboxyl-terminal content, and good color of the product

Active Publication Date: 2022-05-31

JINLIN MEDICAL COLLEGE

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

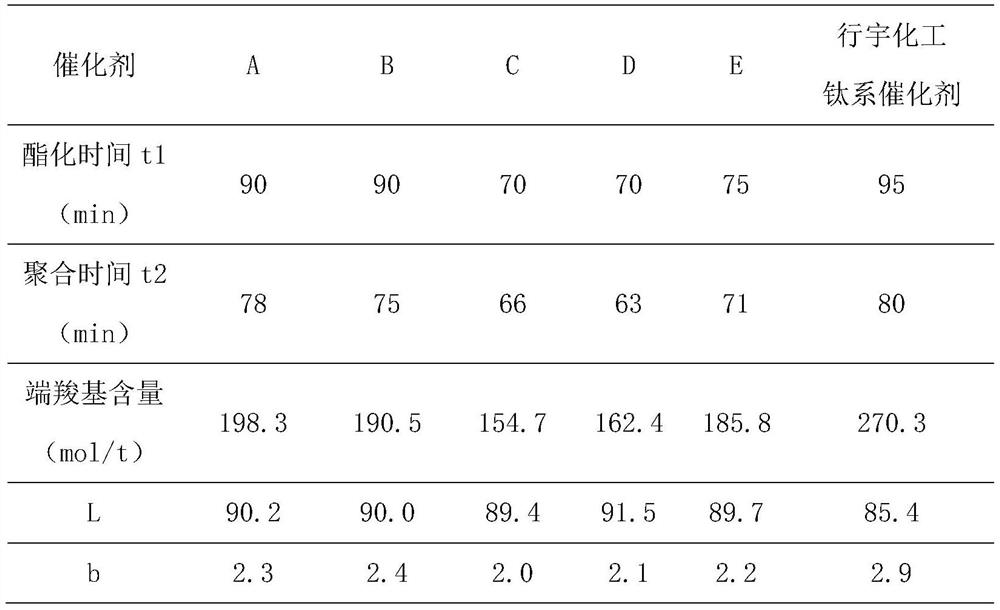

The addition of ruthenium compound in the invention can effectively improve the catalytic activity of the composite catalyst, solve the problem of low catalytic efficiency in the polyester polymerization process, and at the same time, the catalyst can improve the hue of the product

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0019] A liquid-phase titanium composite catalyst, calculated as 100% by mass, is composed of 2-10% titanium compound, 0.5-2% ruthenium

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a liquid-phase titanium-based composite catalyst, a preparation method and its application in the preparation of polyester compounds, and belongs to the technical field of titanium-based catalyst preparation. Calculated by mass sum of 100%, it consists of 2-10% titanium compound, 0.5-2% ruthenium compound, 5-25% polyether polyol compound, 2.5-13% ethylene glycol and 50-90% ethanol are mixed. In the polyester polymerization process, the addition amount of the catalyst is calculated as titanium compound, which is 1 / 1000 to 5 / 1000 of the mass of the carboxylic acid monomer. The liquid-phase composite catalyst prepared by the present invention is mainly a compound formed by mixing titanium compound, ruthenium compound, polyether polyol compound, ethylene glycol and ethanol. Compared with the existing polyester catalyst, It has the advantages of fast catalytic rate, high activity, low residual carboxyl group content, and good color of the product.

Description

A liquid-phase titanium-based composite catalyst, preparation method and preparation method of polyester compound applications technical field The invention belongs to the technical field of titanium-based catalyst preparation, in particular to a liquid-phase titanium-based composite catalyst, preparation The method and its use in the preparation of polyester compounds. Background technique Polyester is not only one of the most important synthetic fiber raw materials, but also has a very important role in engineering plastics and other industrial fields. important use. my country began to study polyester production technology in 1958, and it has strong development strength and solid Base. Since the 1990s, the increasingly fierce competition in the polyester market has prompted various manufacturers to seek to reduce costs. This, the way to enhance competitiveness. Simplifying the process flow, expanding the production scale, and increasing the single-line produc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G63/85C08G63/87C08G63/82C08G63/183

CPCC08G63/85C08G63/87C08G63/826C08G63/183

Inventor 李文亮刘甲雪肖箫崔桂花

Owner JINLIN MEDICAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com