Liquid-phase titanium composite catalyst and preparation method and application of liquid-phase titanium composite catalyst in preparation of polyester compound

A technology of composite catalyst and titanium compound, which is applied in the field of preparation, liquid-phase titanium-based composite catalyst, and polyester compound preparation, can solve the problems of low catalytic efficiency and achieve the effects of fast catalytic rate, good product hue and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

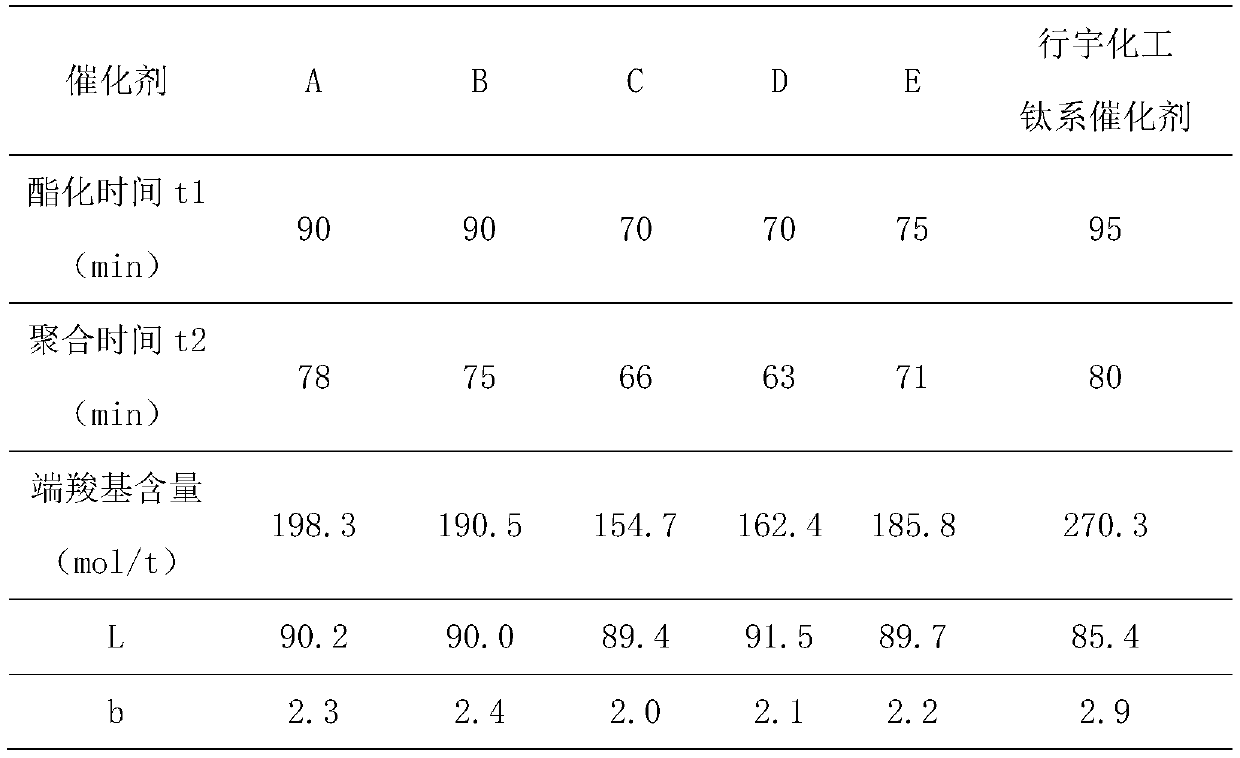

Examples

Embodiment 1

[0019] A liquid-phase titanium-based composite catalyst, calculated as 100% by mass, consists of 2-10% titanium compound, 0.5-2% ruthenium compound, 5-25% polyether polyol compound, 2.5-13% ethylene glycol And 50-90% ethanol mixed.

[0020] A preparation method of a liquid-phase titanium series composite catalyst, the specific steps are as follows:

[0021] Add tetraethyl titanate (5g), terpyridine ruthenium (0.9g), ethylene glycol (10g), polyether polyol (20g) and dehydrated alcohol (64.1g) in the stirrer successively, fully stir 1- 2h, the obtained clear solution is liquid titanium composite catalyst A.

[0022] The application of a liquid phase titanium series composite catalyst in the preparation of polyester compounds is specifically as follows:

[0023] In a 1L polyester reactor, add terephthalic acid (220g), ethylene glycol (120g) and catalyst A (4.4g, the quality of tetraethyl titanate is one thousandth of the quality of terephthalic acid) , then add 1g of stabilize...

Embodiment 2

[0025] A preparation method of a liquid-phase titanium series composite catalyst, the specific steps are as follows:

[0026] Tetraethyl titanate (5 g), ruthenium terpyridine (1.5 g), ethylene glycol (10 g), polyether polyol (25 g) and absolute ethanol (58.5 g) were sequentially added into a stirrer. Thoroughly stir for 1-2h to obtain a clear solution which is liquid titanium-based composite catalyst B.

[0027] The preparation method of the polyester is the same as in Example 1, and the amount of catalyst B used is 4.4 g (the weight of tetraethyl titanate is one thousandth of the mass of terephthalic acid).

Embodiment 3

[0029] A preparation method of a liquid-phase titanium series composite catalyst, the specific steps are as follows:

[0030] Tetraethyl titanate (10 g), ruthenium terpyridyl (0.5 g), ethylene glycol (10 g), polyether polyol (25 g) and absolute ethanol (54.5 g) were successively added into the stirrer. Thoroughly stir for 1-2h to obtain a clear solution which is liquid titanium-based composite catalyst C.

[0031] The preparation method of the polyester is the same as in Example 1, and the amount of catalyst C used is 11 g (the weight of tetraethyl titanate is 5 / 1000 of the mass of terephthalic acid).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com