Preparation and application of high-efficiency fenton catalyst with core-shell iron-carbon micro-electrolysis materials

An iron-carbon micro-electrolysis and micro-electrolysis technology, which is applied in the field of highly toxic pollutant treatment, can solve the problems of affecting the effect and efficiency of wastewater treatment, loss of function, heavy workload, etc., achieve good micro-electrolysis reaction effect, simple preparation method, The effect of high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

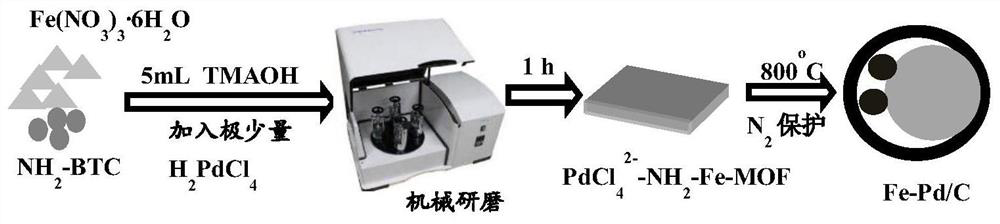

[0039] Example 1 : The preparation method of core-shell type Fe-Pd / C composite Fe-C microelectrolytic material of the present invention

[0040] The synthesizing schematic diagram of the core-shell formula Fe-Pd / C composite Fe-C micro-electrolytic material provided by the present invention is as follows figure 1 Shown, its specific preparation method is:

[0041] First, weigh a certain amount of FeCl 3 , sodium tetrachloropalladate and 2-aminoterephthalic acid are added to the zirconia grinding tank, then a certain volume of tetramethylammonium hydroxide solution and 3-4 zirconia grinding balls are added, and the Grinding at a speed of 0.5-2h to obtain Fe-MOFs-PdCl 2 - Materials; the prepared Fe-MOFs-PdCl 2 - Heating at 800° C. for 2 hours under the protection of nitrogen to obtain a core-shell Fe-Pd / C composite Fe-C micro-electrolytic material.

Embodiment 2

[0042] Example 2 : Structural characterization of the core-shell Fe-Pd / C composite Fe-C microelectrolytic material of the present invention

[0043] This embodiment is the structural characterization of the core-shell Fe-Pd / C composite Fe-C micro-electrolytic material, specifically as follows:

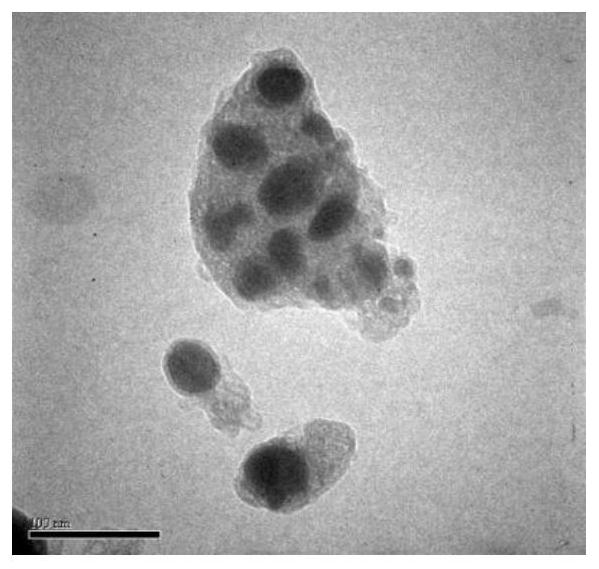

[0044] 1.TEM

[0045] The particle size and morphology of Fe-Pd / C composite Fe-C micro-electrolytic materials were analyzed by transmission electron microscope H7500 (Hitachi, Japan).

[0046] From figure 2 It can be seen that Fe 0 - The particle size of the Pd nanoparticles is 15-30nm, and the thickness of the carbon shell is about 5nm. core-shell Fe 0 -Pd / C embedded in a large amount of graphitized carbon, increasing the core Fe 0 - Stability of Pd.

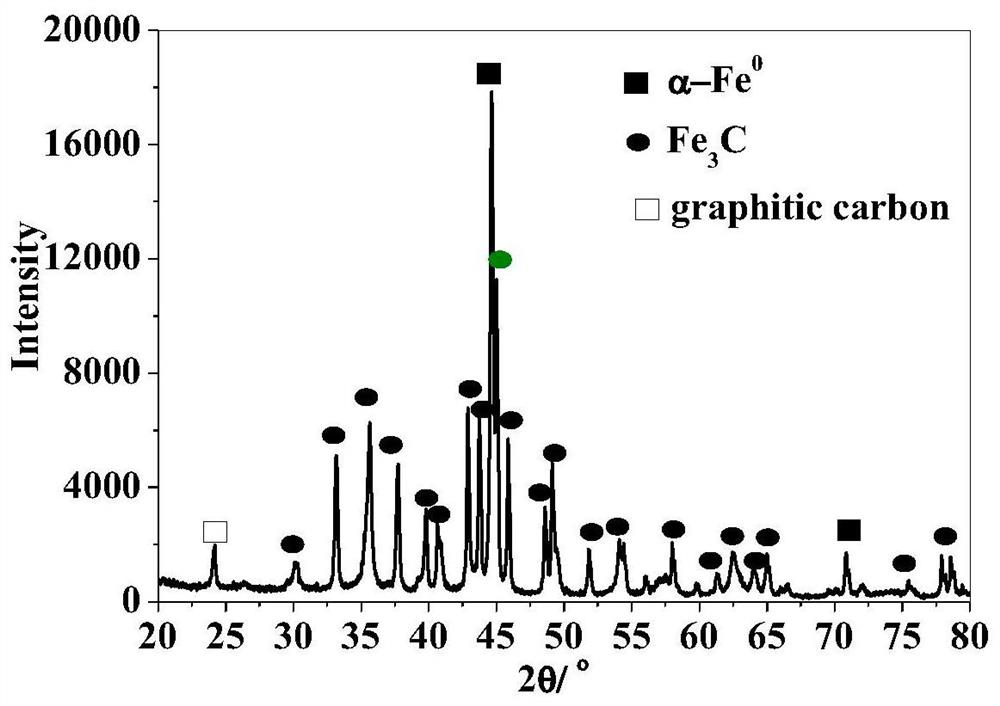

[0047] 2. XRD spectrum

[0048] Fe-MOFs-PdCl prepared by milling method 2 - The X-ray diffraction (XRD) pattern of Fe-Pd / C composite Fe-C microelectrolytic material is obtained on b / max-RB Diffractometer (Rigaku, Japan), usi...

Embodiment 3

[0062] Example 3 : Catalytic performance test of core-shell Fe-Pd / C composite Fe-C micro-electrolytic material of the present invention

[0063] In this example, phenol was selected as a representative, and the catalytic performance of the Fe-Pd / C composite Fe-C micro-electrolytic material was tested.

[0064] The operation steps of the test are as follows: prepare 50 mL of 50 mg / L phenol standard substance, place it in a 100 mL polyethylene plastic vial, add 25 mg of Fe-Pd / C composite Fe-C micro-electrolytic material to make the catalyst concentration 0.5 g / L, and then Add a certain concentration of H 2 o 2 . Shake in a shaker, take 1mL samples at intervals, centrifuge and take the supernatant, respectively for phenol, TOC and Fe 2 + and H 2 o 2 determination. Phenol was measured by HPLC-UV, TOC was detected by TOC / TN analyzer, Fe 2+ and H 2 o 2 Measured with a UV-Vis spectrophotometer.

[0065] The conditions of HPLC-UV method determination are as follows:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com