Cheese dyeing feeding device

A cheese and dyeing machine technology, which is applied in the processing of textile materials, processing textile material carriers, liquid/gas/steam textile material processing, etc., can solve the problems of no positioning mechanism, etc., and achieve the effect of improving dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

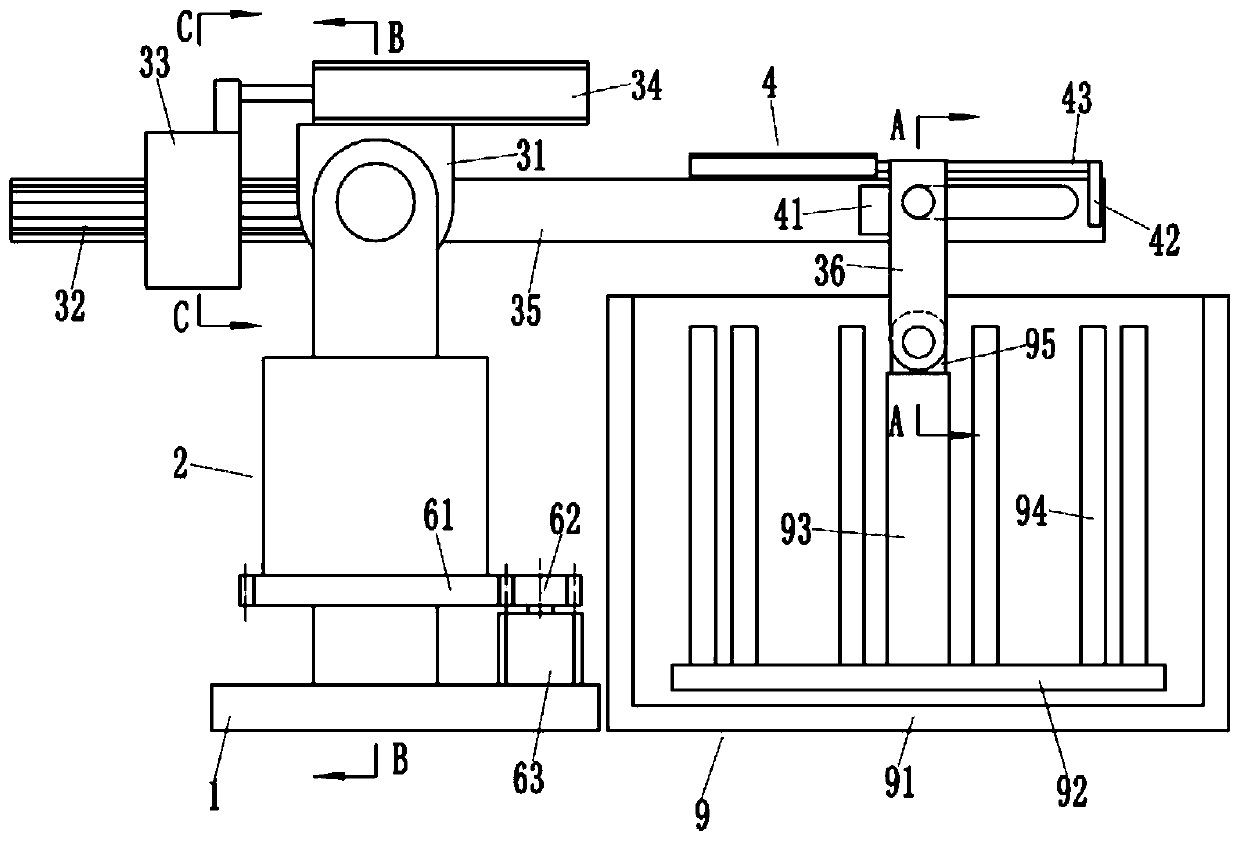

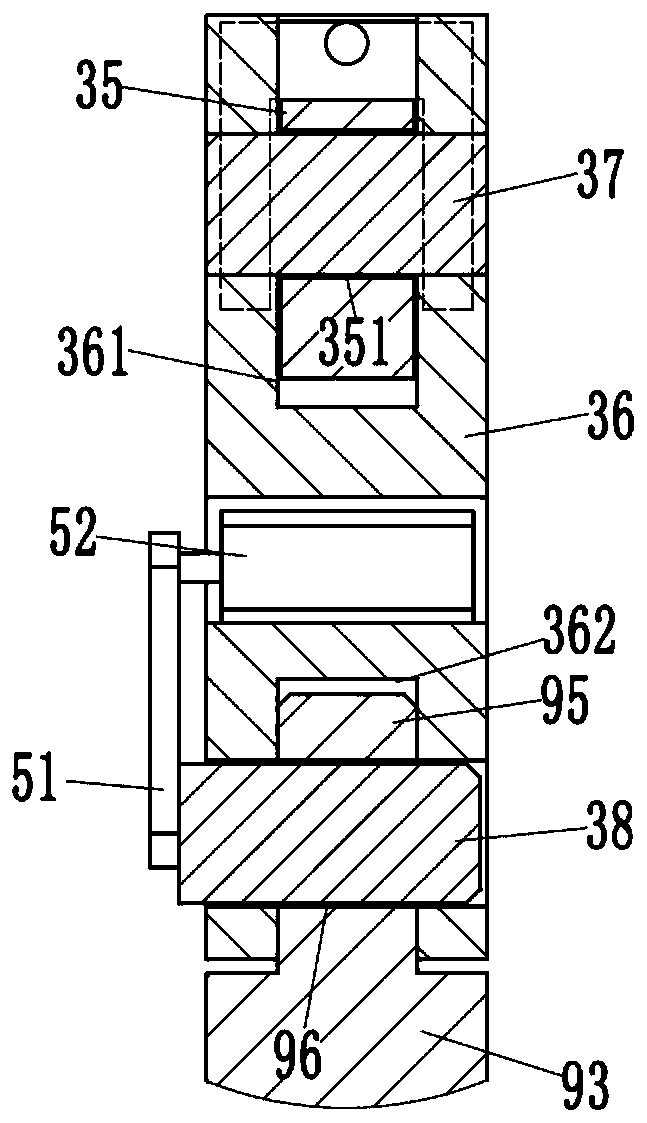

[0018] Examples, see e.g. Figure 1 to Figure 4 As shown, a cheese dyeing and feeding device includes a base 1 fixed on the left and right sides of the frame and a dyeing machine 9. The dyeing machine 9 includes a housing 91 and a tray 92 arranged in the housing 91. On the tray 92 A central suspender 93 and a plurality of fixed poles 94 uniformly distributed around the circumference of the central suspender 93 are fixed; a half-waist block 95 is fixed on the upper end of the central suspender 93, and the half-waist block 95 is formed with a connection through the front and rear directions. hole 96;

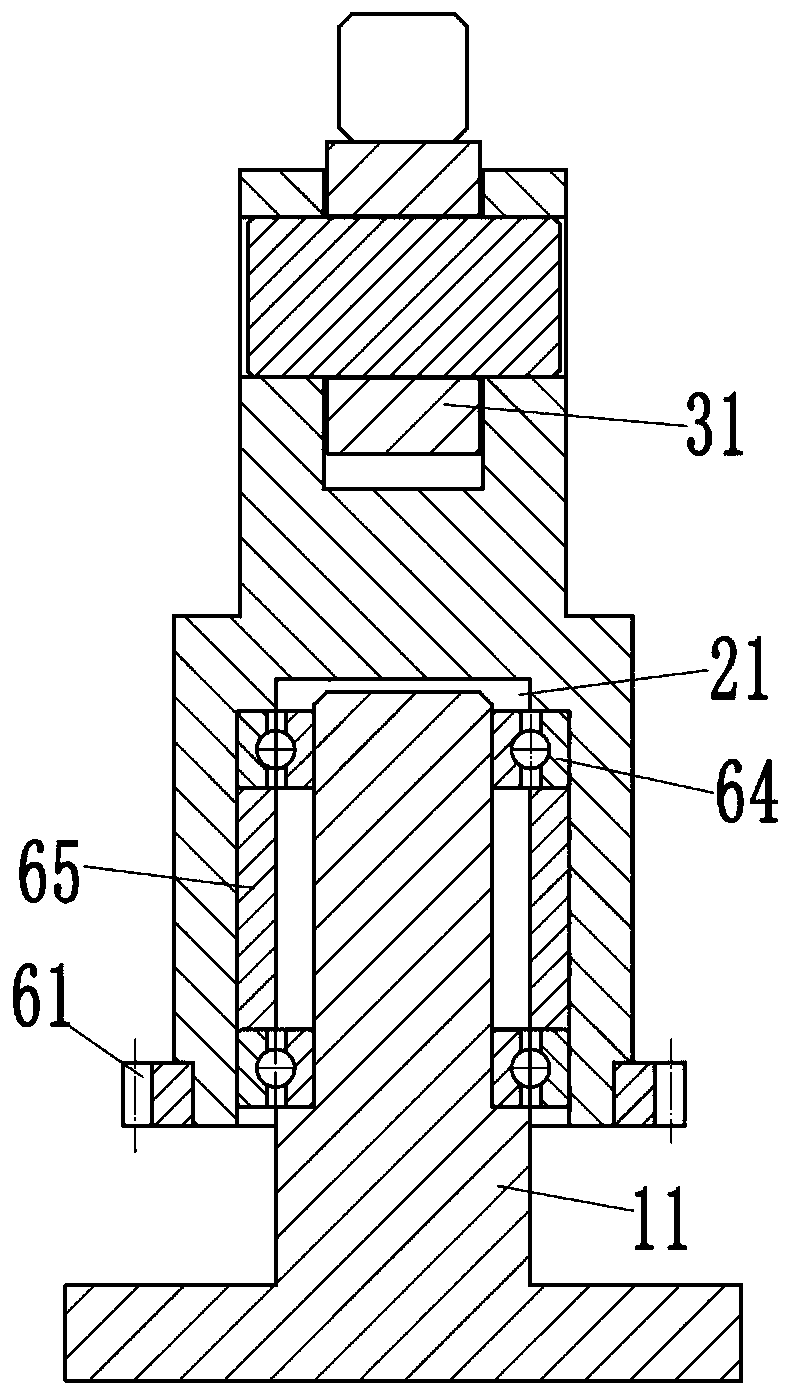

[0019] The base 1 is provided with a rotatable swivel seat 2, the upper end of the swivel seat 2 is hinged with a turntable 31, the left side wall of the turntable 31 is fixed with a slide rail 32, and the slide rail 32 is slidably connected with a load-bearing block 33, The load-bearing block 33 is fixedly connected with the piston rod of the first cylinder 34 fixed on the turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com