Turnable ditch pouring modular reverse formwork system

A modular and systematic technology, applied in construction, water conservancy projects, artificial waterways, etc., can solve problems such as the inability to guarantee the verticality and positioning accuracy of the reverse formwork formwork, the inability to adjust the length of the inner support, and the difficulty in local adjustment of the inner support. Achieve the effect of improving material turnover rate, improving construction efficiency and construction quality, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the invention will be further elaborated below in conjunction with specific illustrations.

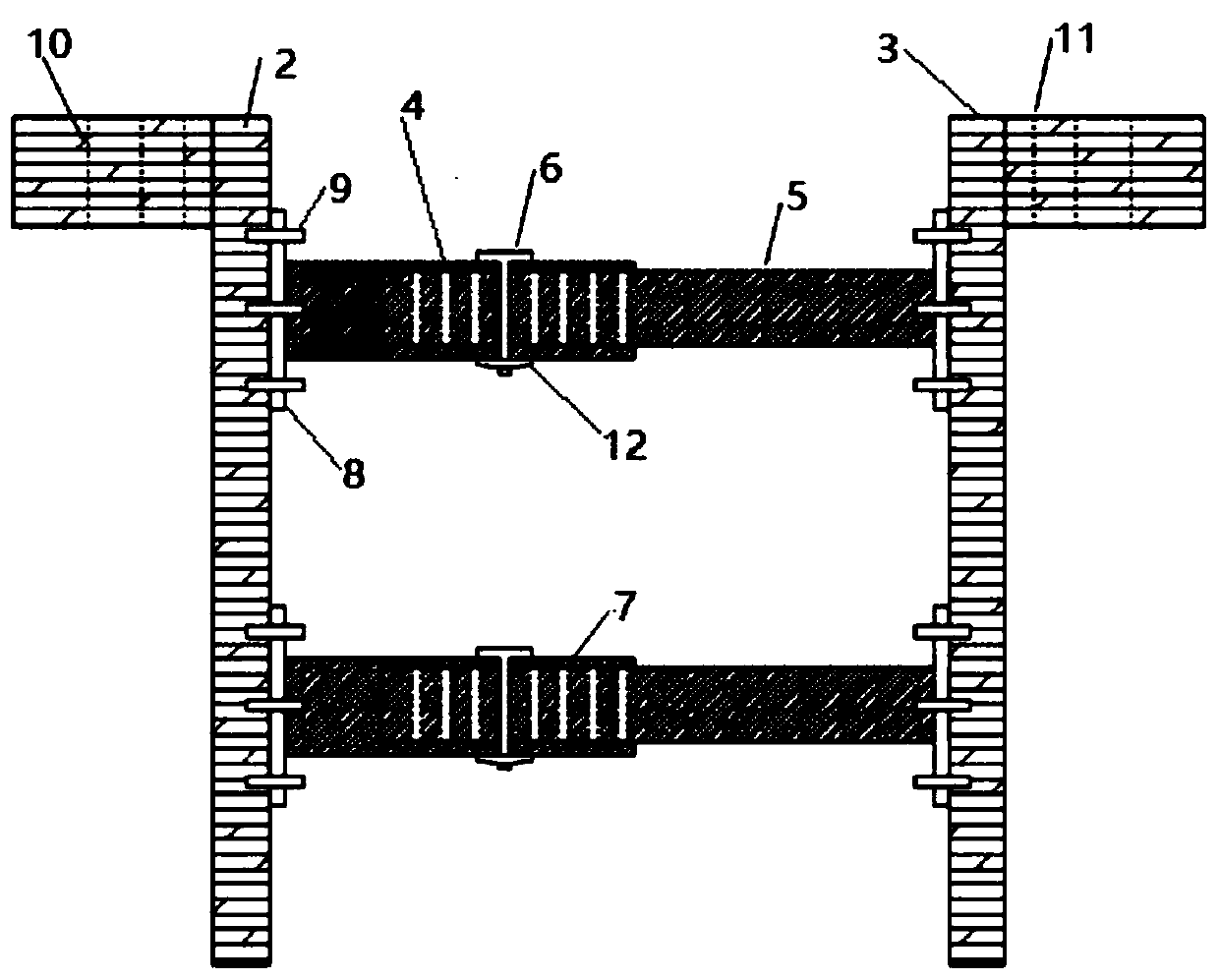

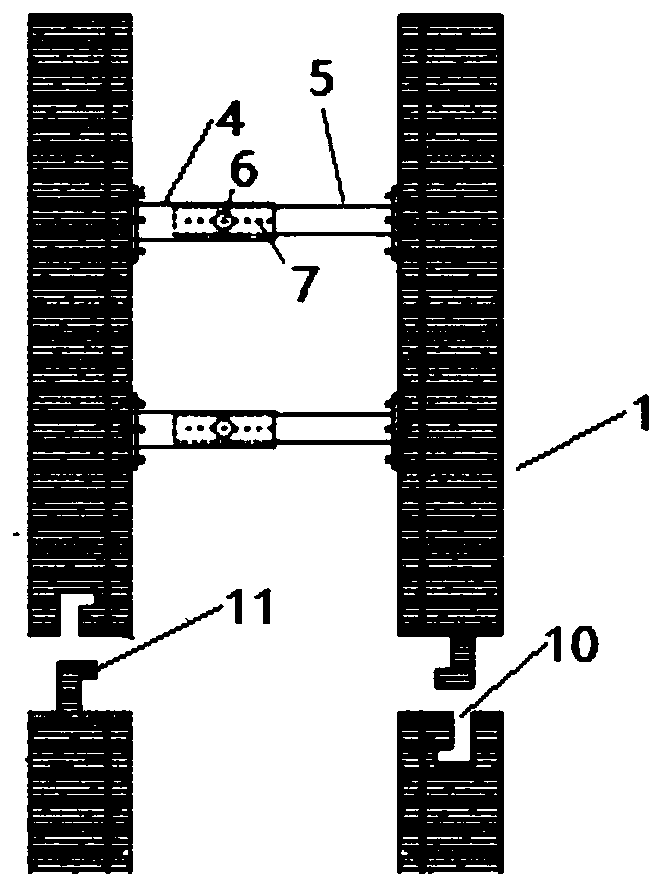

[0017] Such as Figure 1-2 As shown, the present embodiment is spliced by two support units 1. The support unit 1 includes a left formwork 2 and a right formwork 3, and four adjustable support steel pipes arranged between the left formwork 2 and the right formwork 3. two.

[0018] Further, the adjustable support steel pipe includes a DN50 left support steel pipe 4 with an outer diameter of 60.3 and a DN50 right support steel pipe 5 with an outer diameter of 56.2. The right support steel pipe 5 is embedded inside the left support steel pipe 4, and the adjustable support There are eight reserved holes 7 at intervals of 10cm at the nesting places of the left and right supporting steel pipes (4, 5) on the steel pipe, which can be penetrated by super-lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com