Electromagnetic adjustable vibration damper

A shock absorber and electromagnetic technology, applied in the direction of spring/shock absorber, spring/shock absorber design features, coil spring, etc., can solve problems such as real-time adjustment of shock absorber strength without specific solutions, and achieve response Sensitive, avoid high temperature work, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

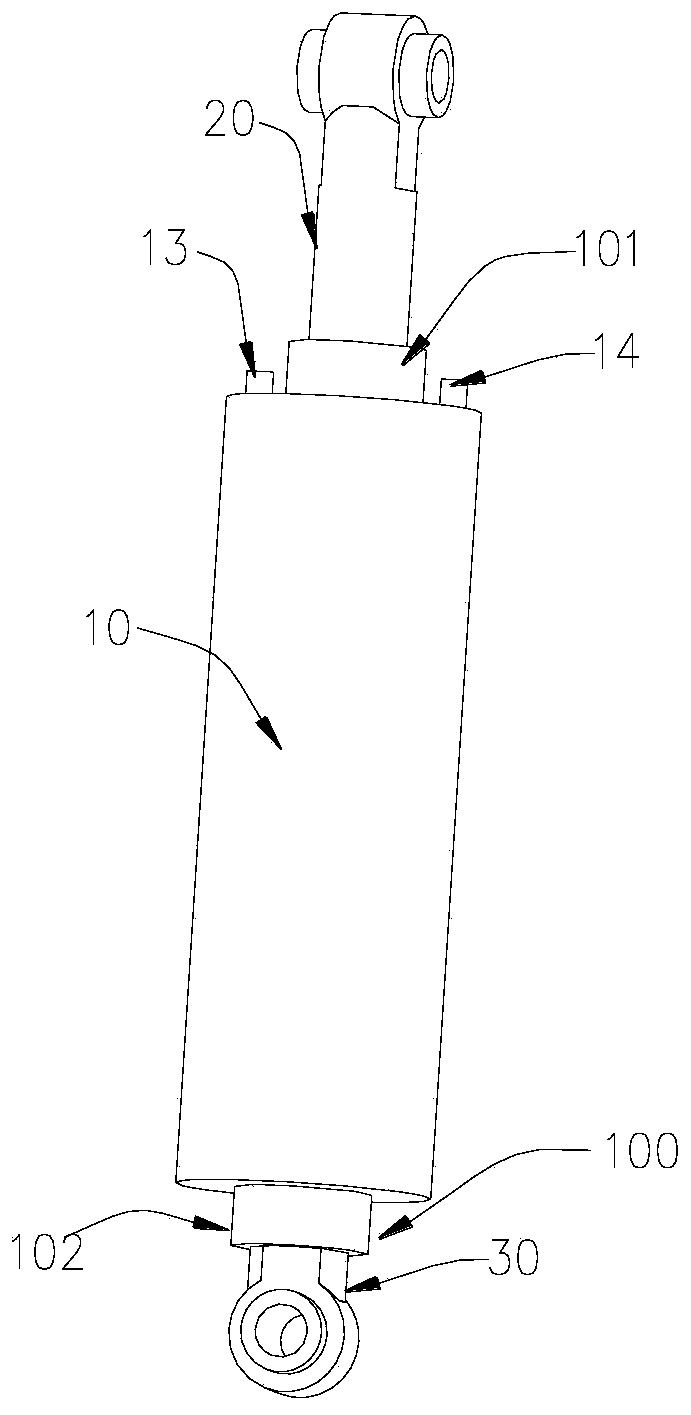

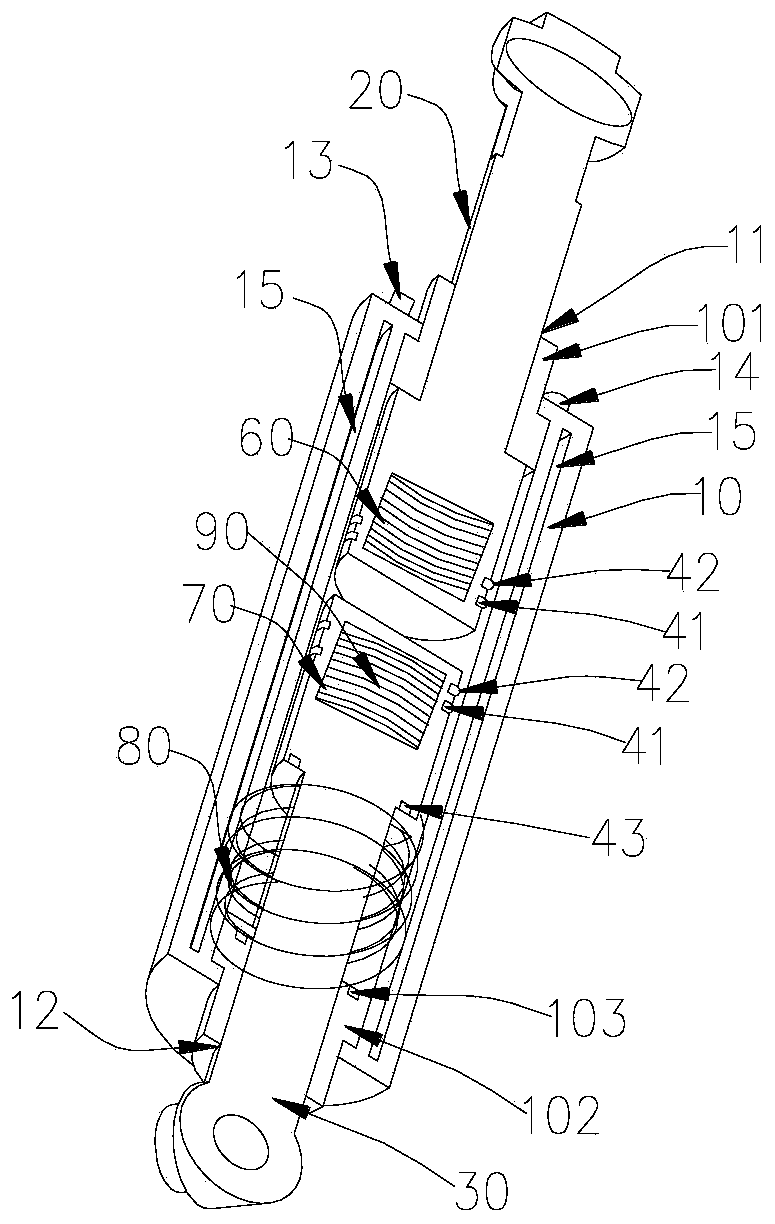

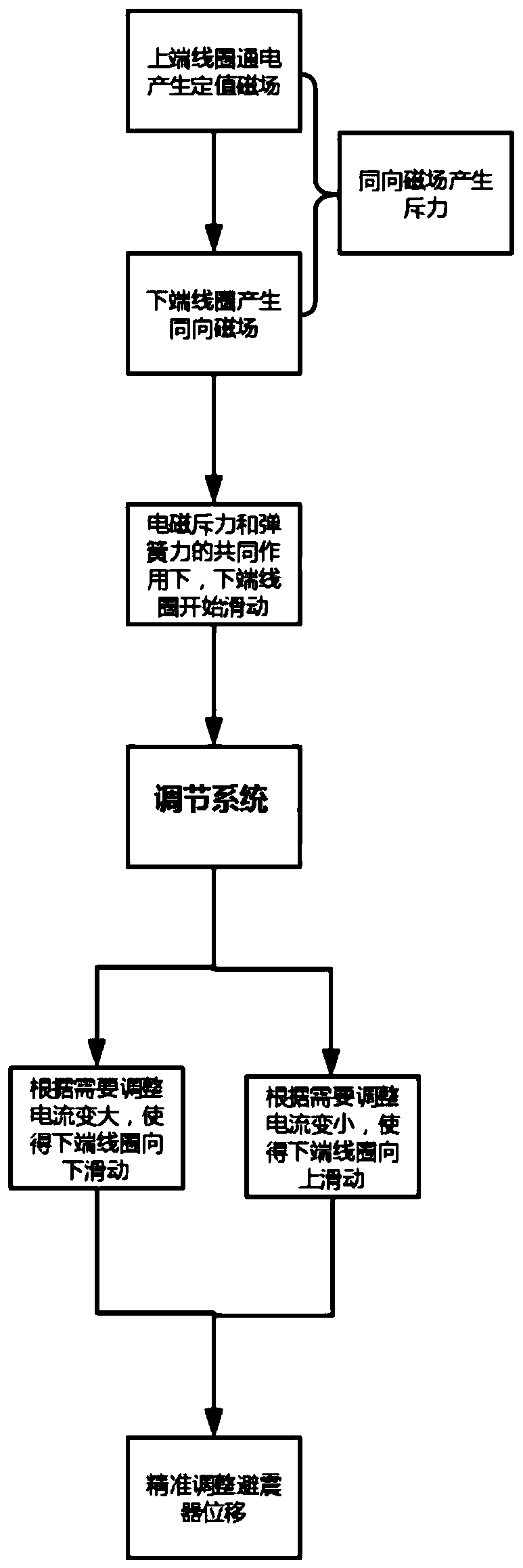

[0027] An electromagnetic adjustable shock absorber, such as Figure 1-4 Shown, comprise cylinder body 10, first piston device 20, second piston device 30, described first piston device 20 and described second piston device 30 all comprise piston head 40 and piston rod 50, described cylinder body 10 One end of the cylinder body 10 is provided with a first through hole 11, and the other end of the cylinder body 10 is provided with a second through hole 12, and the lower end of the piston rod 50 of the first piston device 20 extends into the upper part of the inner cavity of the cylinder body 10. The upper end of the piston rod 50 of the second piston device 30 extends into the lower part of the inner cavity of the cylinder body 10, the first through hole 11 is matched with the outer circle of the piston rod 50 of the first piston device 20, and the second through hole 12 is matched with the first piston rod 50 of the first piston device 20. The piston rods 50 of the two piston ...

Embodiment 2

[0031] An electromagnetic adjustable shock absorber, such as Figure 1-4 Shown, comprise cylinder body 10, first piston device 20, second piston device 30, described first piston device 20 and described second piston device 30 all comprise piston head 40 and piston rod 50, described cylinder body 10 One end of the cylinder body 10 is provided with a first through hole 11, and the other end of the cylinder body 10 is provided with a second through hole 12, and the lower end of the piston rod 50 of the first piston device 20 extends into the upper part of the inner cavity of the cylinder body 10. The upper end of the piston rod 50 of the second piston device 30 extends into the lower part of the inner cavity of the cylinder body 10, the first through hole 11 is matched with the outer circle of the piston rod 50 of the first piston device 20, and the second through hole 12 is matched with the first piston rod 50 of the first piston device 20. The piston rods 50 of the two piston ...

Embodiment 3

[0037] An electromagnetic adjustable shock absorber, such as Figure 1-4 Shown, comprise cylinder body 10, first piston device 20, second piston device 30, described first piston device 20 and described second piston device 30 all comprise piston head 40 and piston rod 50, described cylinder body 10 One end of the cylinder body 10 is provided with a first through hole 11, and the other end of the cylinder body 10 is provided with a second through hole 12, and the lower end of the piston rod 50 of the first piston device 20 extends into the upper part of the inner cavity of the cylinder body 10. The upper end of the piston rod 50 of the second piston device 30 extends into the lower part of the inner cavity of the cylinder body 10, the first through hole 11 is matched with the outer circle of the piston rod 50 of the first piston device 20, and the second through hole 12 is matched with the first piston rod 50 of the first piston device 20. The piston rods 50 of the two piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com