Anti-misrecognition control method and device for gearbox friction plate set automatic assembling

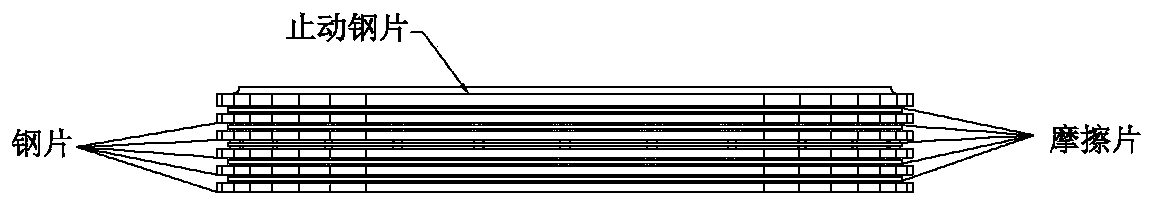

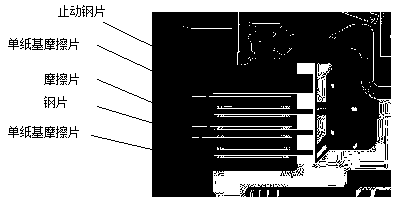

A friction plate set and control method technology, which are applied in cleaning methods using gas flow, transmission parts, chemical instruments and methods, etc., can solve the problem of easy dropping of paper-based particles, failure of gearbox performance, and dropping of paper-based impurities. and other problems, to achieve the effect of reducing the workload of manual operation, improving work efficiency, and reducing the rhythm of the station

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

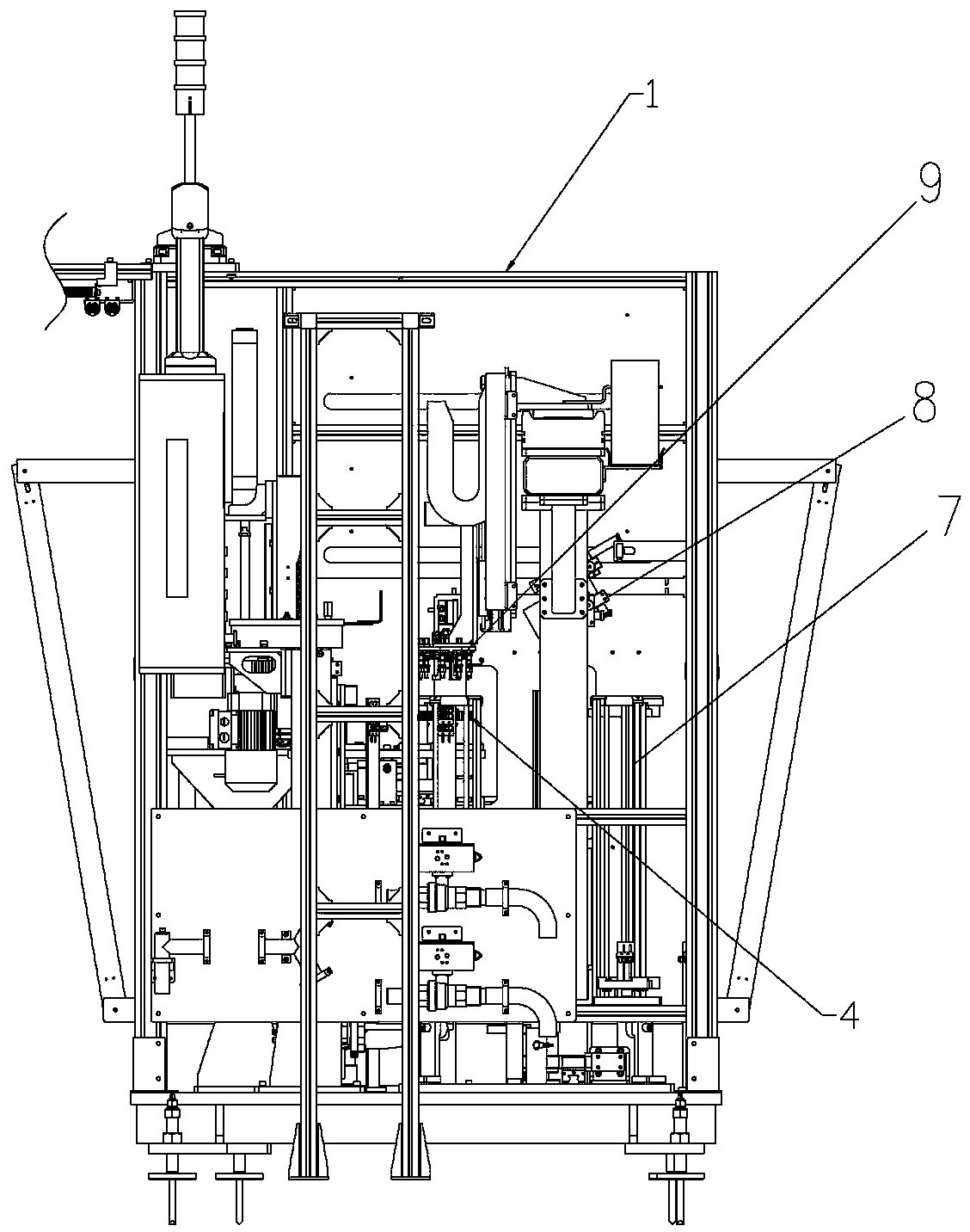

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings. Those skilled in the art should understand that the following does not constitute a limitation to the protection scope of the present invention.

[0039] Examples such as Figure 3-Figure 7 As shown, an error-proof identification control method for the automatic assembly of gearbox friction plate sets, the device for realizing the error-proof identification control method includes a stacking positioning device 4, a photographic error-proofing device 8, a stacking positioning device 4, and a photographic error-proofing device 8 is set on the frame 1 of the friction plate group automatic assembly device, and the camera error prevention device 8 is set on the upper side of the stacking positioning device 4, the air nozzle 6 is set above the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com