Deicing method and device of dehumidifier defrosting tray

A water-receiving pan and dehumidifier technology, applied in refrigerators, compressors, heating methods, etc., can solve the problems of energy waste, freezing of water-receiving pans, and easy frosting of dehumidifiers, so as to achieve good energy-saving effect and maintain reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

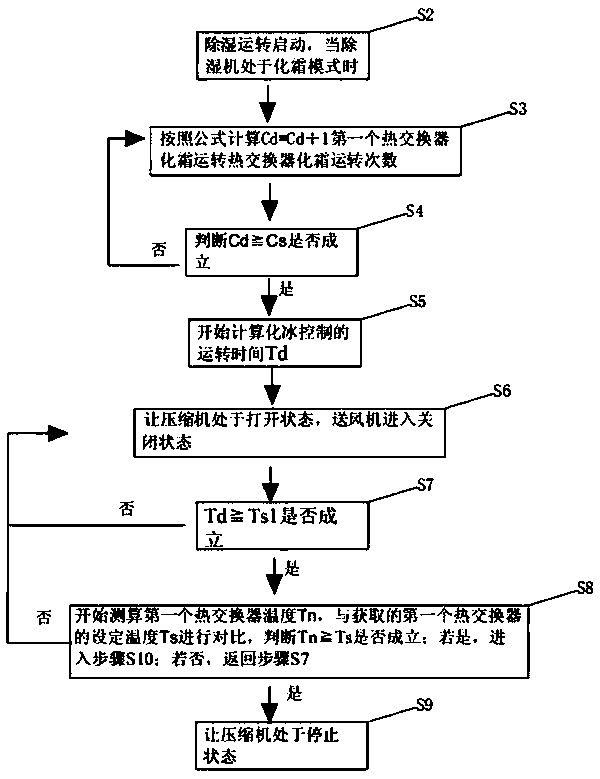

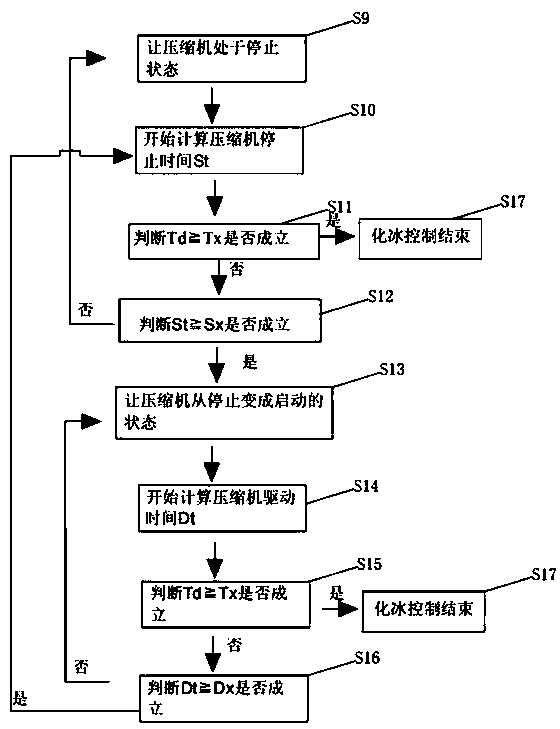

[0040] Such as Figure 1-Figure 2 As shown, a deicing method for a water tray of a dehumidifier provided in this embodiment specifically includes the following steps:

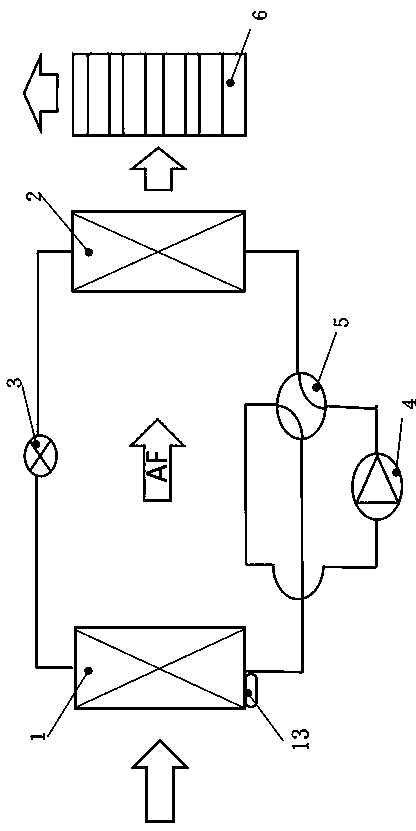

[0041] S1. Provide a dehumidifier, which includes a first heat exchanger, a second heat exchanger, a compressor, a pressure reducer, a fan, a four-way reversing valve, and a temperature detector installed on the first heat exchanger;

[0042] S2. The dehumidification operation starts, when the dehumidifier is in the defrosting mode;

[0043] S3. Accumulate the number of times of dehumidification according to the formula Cd=Cd+1, and obtain the number of defrosting operations Cd of the first heat exchanger defrosting operation;

[0044] S4. Obtain the pre-set defrosting times Cs of the heat exchanger, and judge whether Cd≧Cs is established; if yes, enter step S5; if not, return to step S2;

[0045] S5. It is considered that the deicing control of the water receiving tray is started, and at this time, the runni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com