Blade type high-frequency air pressure sensor detection device

A technology of air pressure sensor and detection device, which is applied to measurement devices, instruments, and vibration measurement, etc., can solve the problems of low efficiency and accuracy, low frequency bandwidth to be measured, and difficulty in quick delivery detection, so as to avoid safety problems and improve control comfort. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

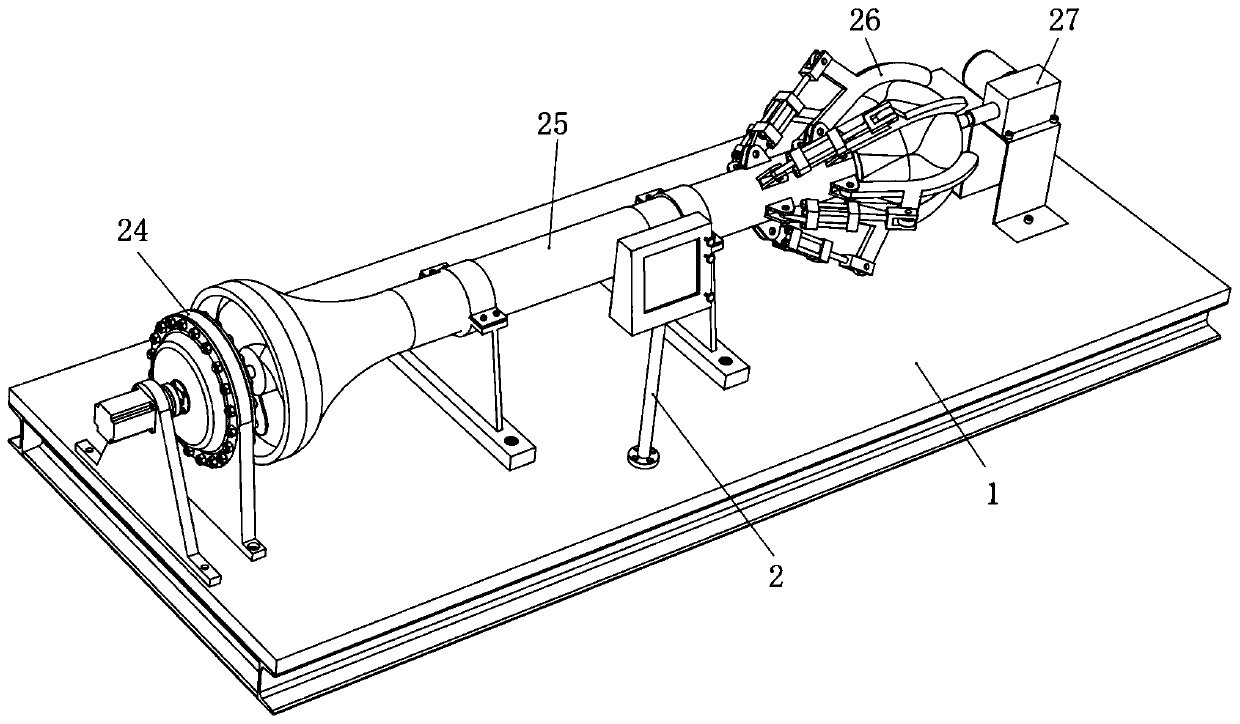

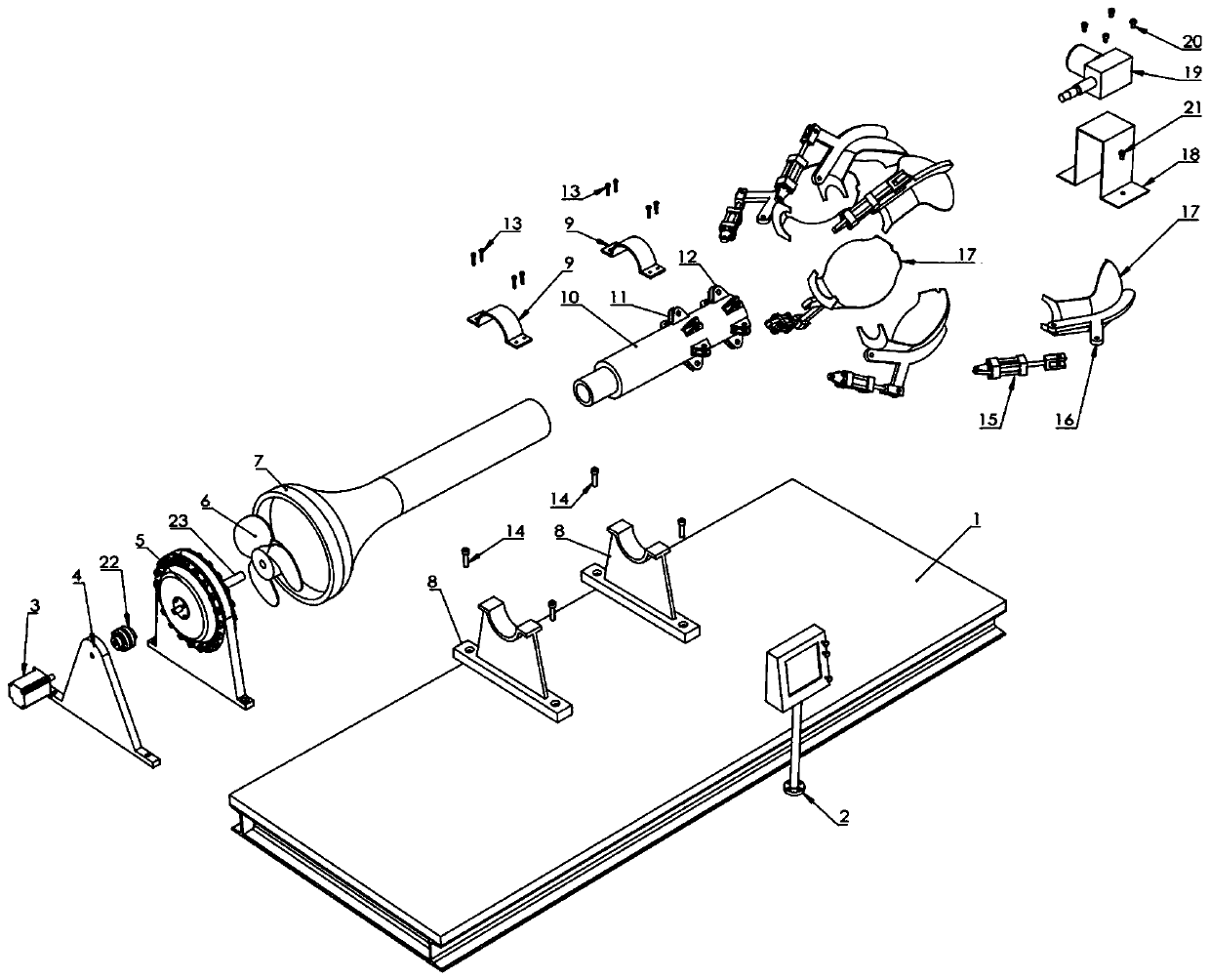

[0021] figure 1 It is an assembly diagram of the vane-type high-frequency air pressure sensor detection system. It can be seen from the figure that the system is mainly composed of base 1, numerical control display system 2, motor-speed increaser assembly 24, impeller 6, air duct assembly 25, opening width control assembly It is composed of parts such as 26 and sensor assembly 27.

[0022] The numerical control display system is used to display various parameter information such as the current system operating status and pressure frequency, and is responsible for the overall control of the system. The motor-gearbox assembly is used to adjust the rotation speed of the impeller and is also the power source for generating high-pressure gas waves. Different test frequency requirements can be realized by adjusting the speed of the motor. The impeller rotates to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com