Double-station FPC supplementary material deviation and re-pasting/missing-pasting inspection machine

A dual-station, inspection machine technology, applied in the analysis of materials, optical testing of flaws/defects, and material analysis by optical means, can solve problems such as false detection, eliminate measurement errors, improve inspection accuracy, and shorten the inspection process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

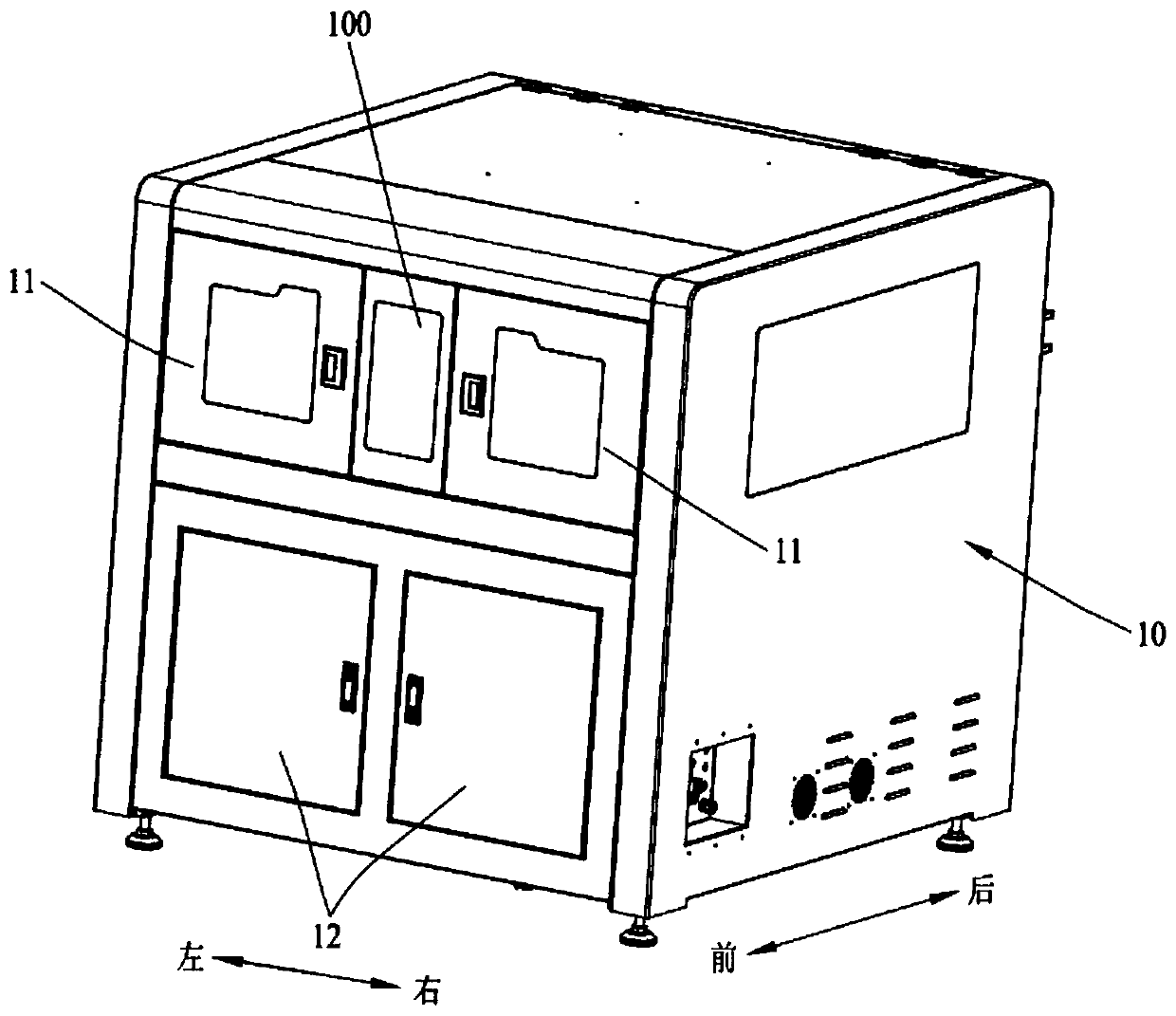

[0029] see figure 1 , the dual-station FPC supplementary material offset of the preferred embodiment of the present invention, re-posting / missing pasting inspection machine includes a cabinet 10 and a control system with a display and a touch screen 100, and the cabinet 10 corresponds to the loading platform 71 and the blanking Platform 72 (see figure 2 ) are respectively provided with openable and closable front doors 11, and the bottom of the front door 11 is provided with openable and closable maintenance cabinet doors 12. The front door 11 has a hinged side hinged with the cabinet 10 , and nitrogen springs are arranged between the cabinet 10 and both sides of the front door 11 adjacent to the hinged side, so that the front door 11 can be opened and closed.

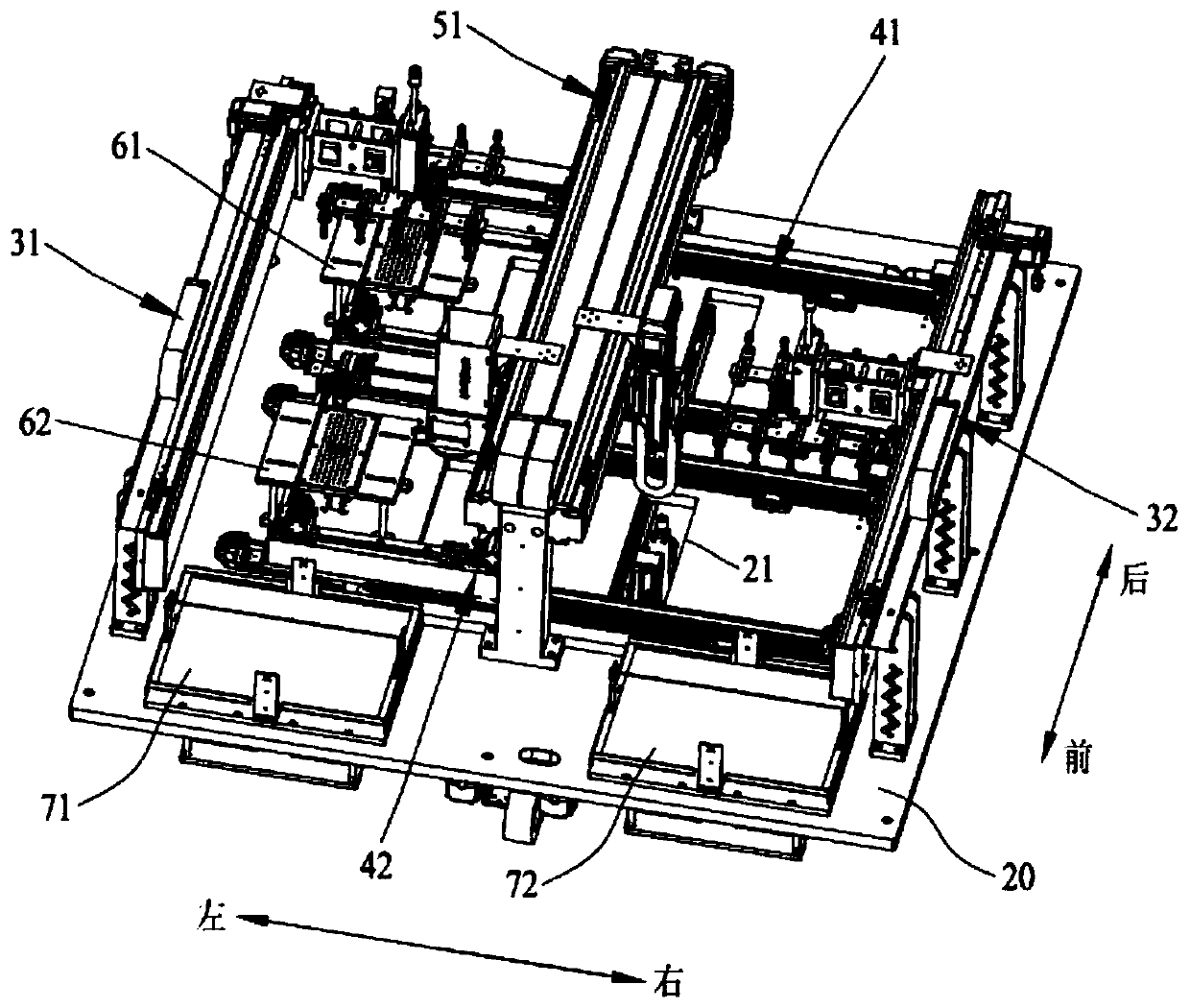

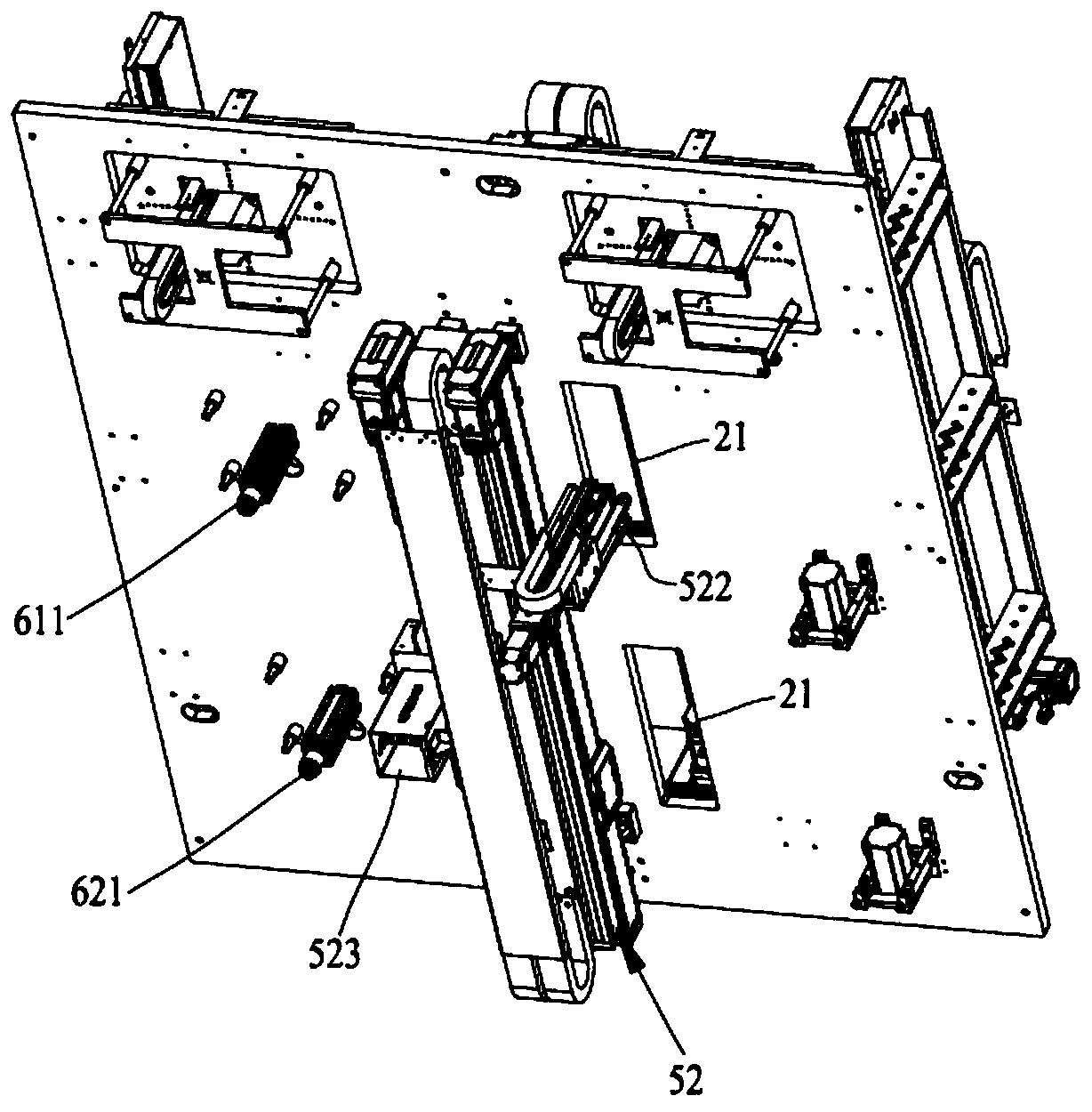

[0030] figure 2 and 3 The internal structure of a preferred embodiment of the inspection machine is shown. see figure 2 , there is an installation carrier 20 arranged horizontally in the cabinet 10, and the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com