Constant-temperature structure for high-performance humidity detection device and preparation method

A humidity detection, high-performance technology, applied in the field of sensors, can solve the problems of high cost, affecting the accuracy of humidity detection, bulky, etc., to achieve the effect of reducing equipment cost, saving assembly space, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

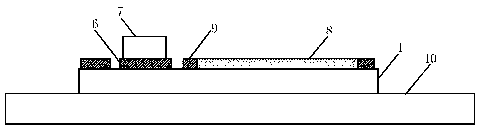

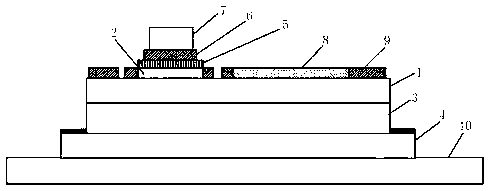

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0033] Example. A constant temperature structure for a high-performance humidity detection device, consisting of figure 2 shown, including top Al 3 N 4 Substrate 1, top layer Al 3 N 4 A thin film thermistor 2 is integrated on the upper surface of the substrate 1, and the top layer of Al 3 N 4 The lower surface of the substrate 1 is integrated with a TEC unit 3, and the lower surface of the TEC unit 3 is integrated with an underlying Al 3 N 4 The substrate 4; the upper surface of the thin film thermistor 2 is integrated with an insulating medium layer 5 , and the upper surface of the insulating medium layer 5 is pasted with a sensor signal processing chip 7 via a metallization layer 6 .

[0034] figure 2 In , the black square bars on both sides of TEC unit 3 are its pins.

[0035] The afo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com