Dam crack detection underwater robot and using method

A robot and water detection technology, which is applied to underwater operation equipment, instruments, measuring devices, etc., can solve the problems of difficulty and low precision in detecting cracks in underwater dams, and achieve the effects of stable motion, high detection efficiency and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

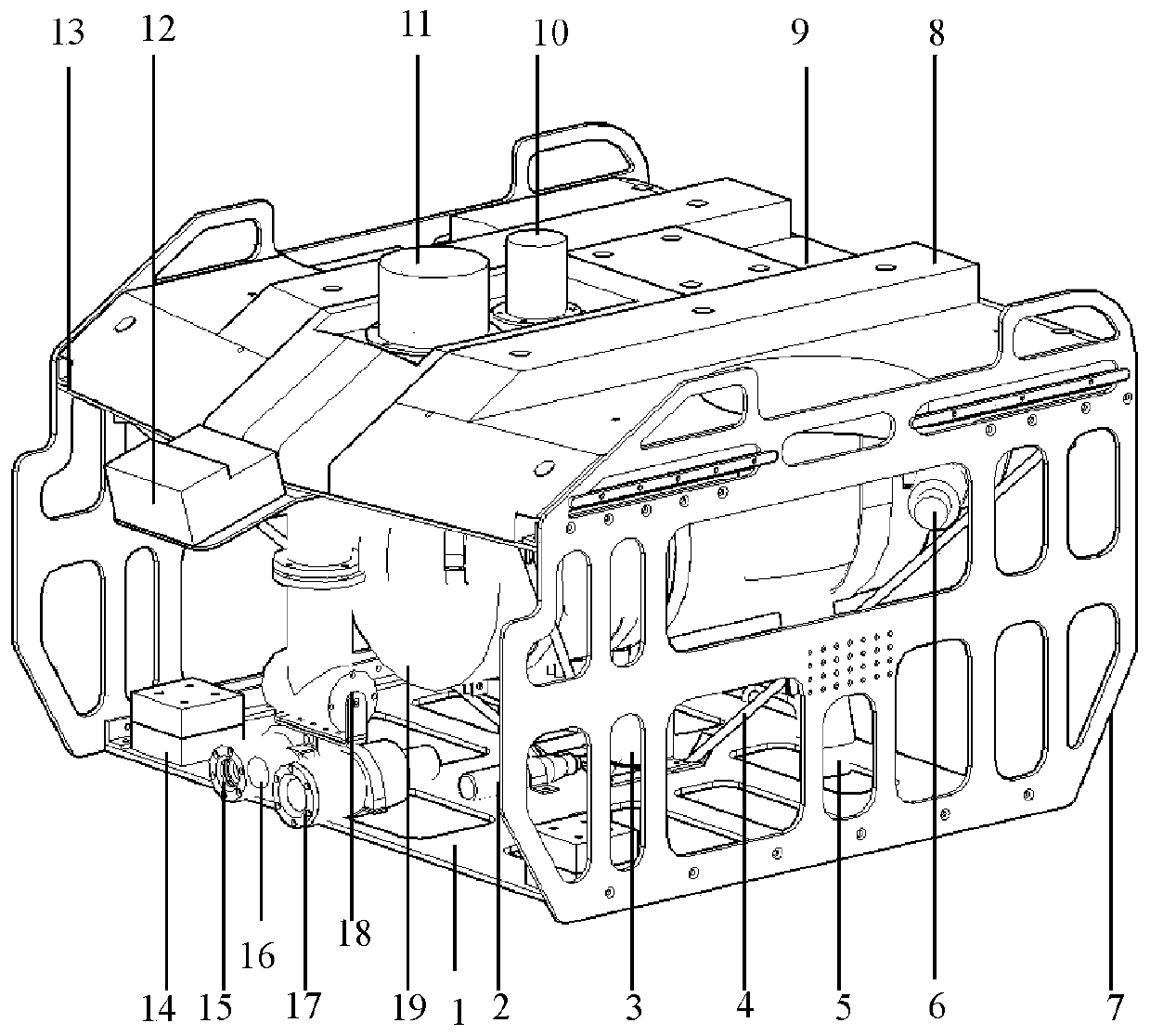

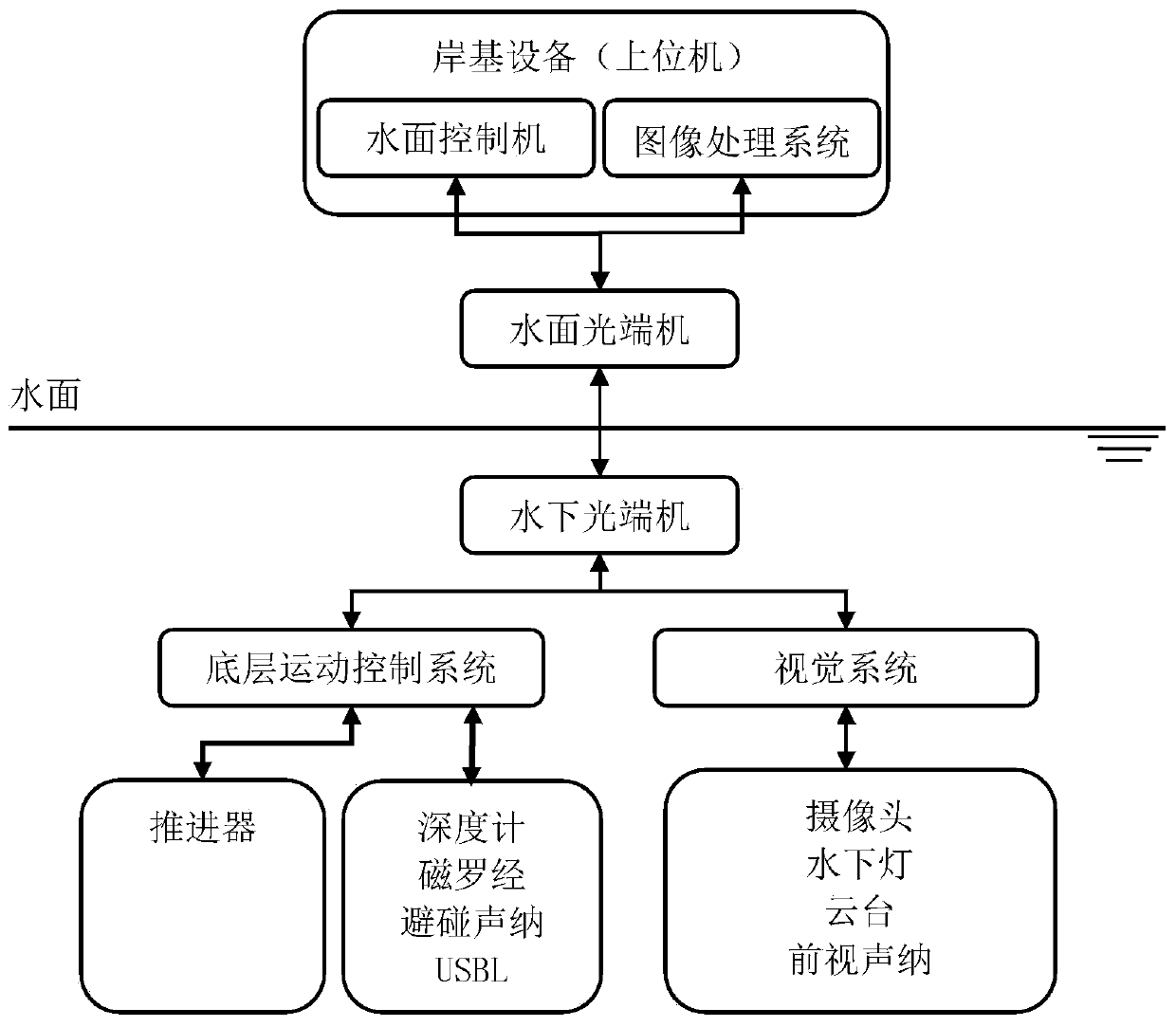

[0023] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a kind of dam crack detection underwater robot described in this embodiment includes a carrier frame, a power system, a crack detection system, a navigation and positioning system, a buoyancy balance system, a pressure chamber and a lower computer system 19; the power system , the crack detection system, the navigation and positioning system, the buoyancy balance system, the pressure chamber and the lower computer system 19 are all installed in the carrier frame.

[0024] In this embodiment, the pressure-resistant cabin and the pressure-resistant cabin of the lower computer system 19 are processed by 5A06 aluminum alloy pipes, and the surface is treated with waterproof oxidation, equipped with two ribs to strengthen the structure, and the O-ring is used for axial sealing. It is airtight and can withstand the pressure of 100 meters of water depth; the pressure cabin and the lower co...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination Figure 1 to Figure 4 Describe this embodiment, the carrier frame of a kind of embankment crack detection underwater robot described in this embodiment comprises base plate 1, upper panel 13, two side fixing plates 7 and four tie bars 4, upper panel 13, base plate 1 are formed by upper Horizontally arranged successively from the bottom, two side fixing plates 7 are vertically arranged side by side between the upper panel 13 and the bottom plate 1, and the upper edge of the side fixing plate 7 is fixedly connected with the upper panel 13, and the lower edge of the side fixing plate 7 is connected with the bottom plate 1 is fixedly connected, and the four tie bars 4 hold the center of the bottom plate 1 and the four corners of the upper panel 13 respectively.

[0027] The bottom plate 1, the upper panel 13, and the two side fixing plates 7 are all made of 6mm thick aluminum alloy plate, so that the structure of the robot can b...

specific Embodiment approach 3

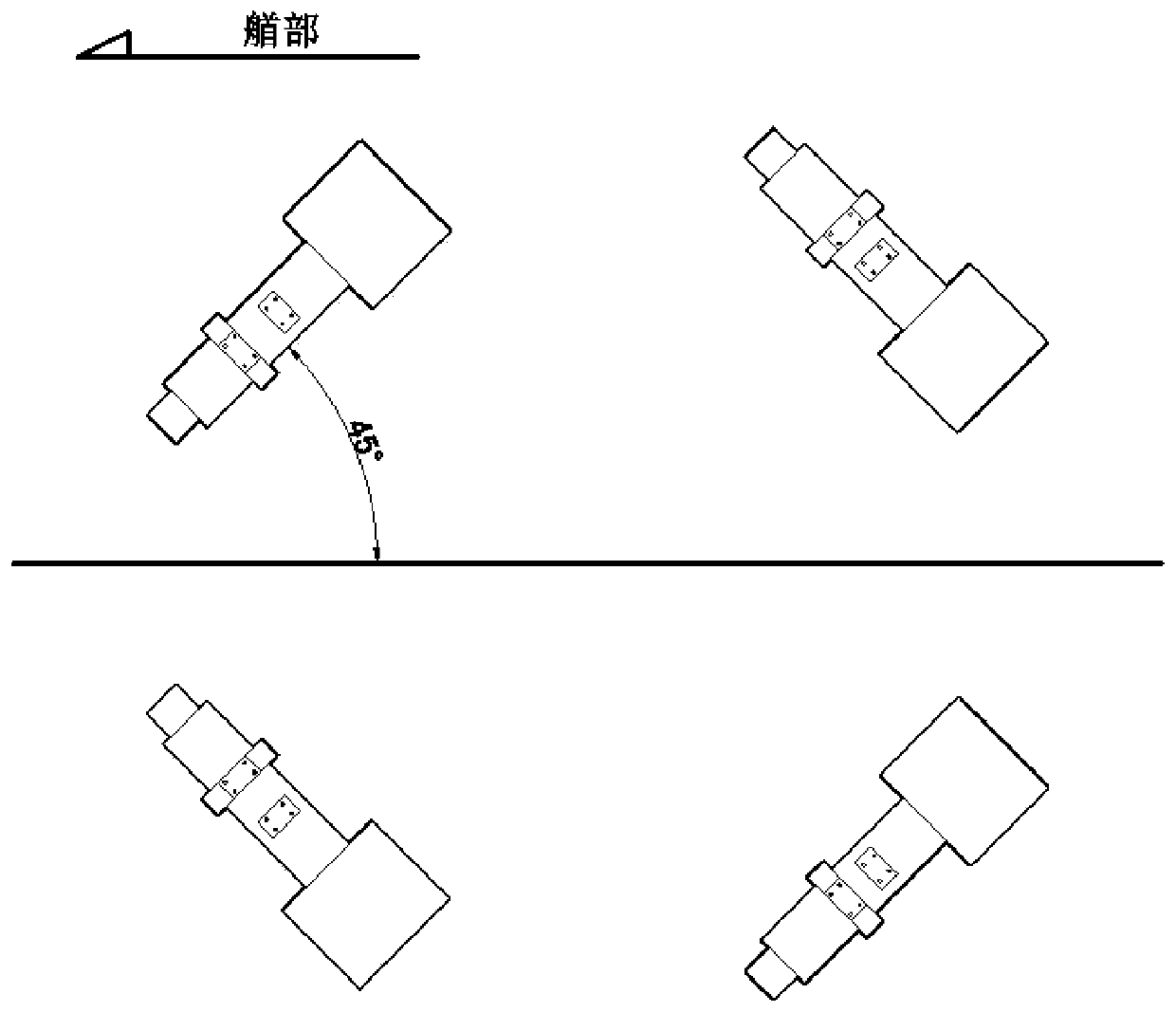

[0029] Specific implementation mode three: combination Figure 1 to Figure 4 Describe this embodiment, the power system of a dam crack detection underwater robot described in this embodiment includes two vertical propellers 5 and four horizontal propellers 6, and the two vertical propellers 5 are respectively installed on two sides On the board 3, four horizontal propellers 6 are installed on the four corners of the upper panel 13 respectively.

[0030] In this embodiment, the horizontal propellers 6 are respectively arranged at the four corners of the robot, forming an angle of 45 degrees with the longitudinal axis of the robot, so as to realize the forward and backward movement, left and right lateral movement, and bow turning movement of the robot. The vertical propellers 5 are arranged on both sides of the robot, and The longitudinal coordinates of the center of gravity and the center of buoyancy are the same, forming an angle of 15 degrees with the vertical line to realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com