Deformable mirror surface shape design method and device for free-form surface measurement

A design method and technology of deformable mirrors, which are applied in the direction of measuring devices, optical devices, optics, etc., to achieve the effect of high-precision detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

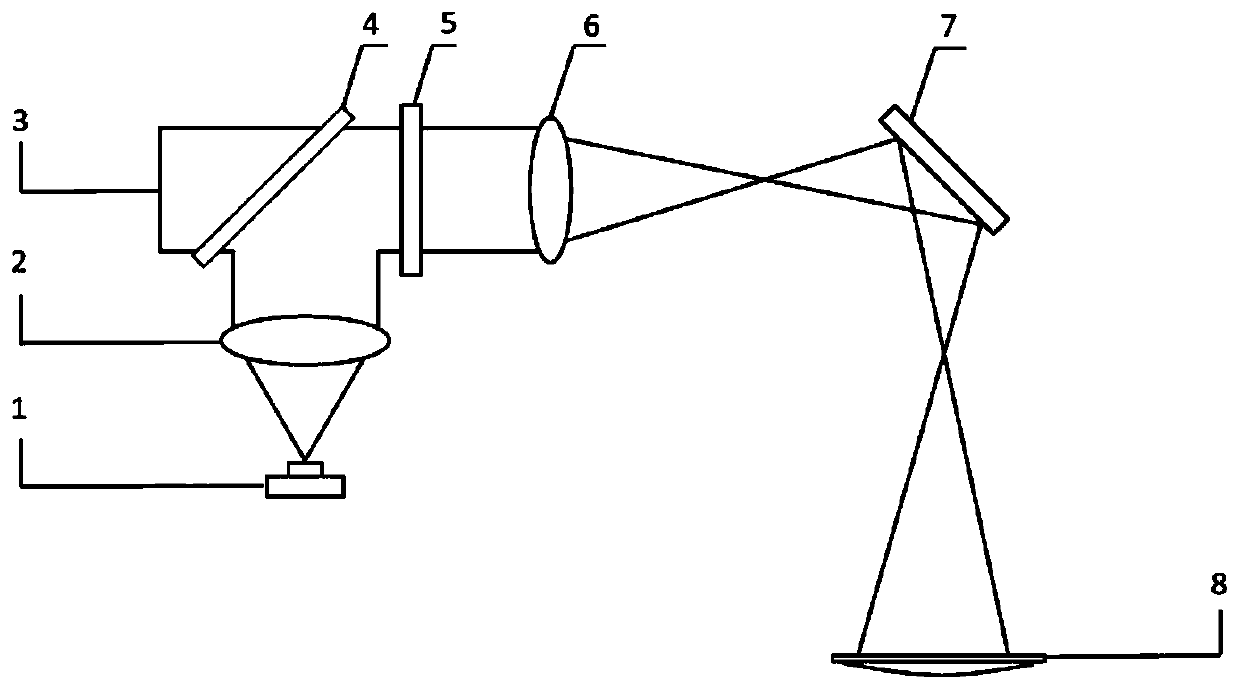

[0025] The surface of the deformable mirror has a high degree of freedom, which makes it a part of the compensator measurement system with other optical lenses, and can realize the instantaneous detection of various free-form surfaces. Compared with the traditional partial compensator, the deformable mirror partial compensator has technical advantages such as simple structure, low design difficulty and remarkable compensation effect. The deformable mirror surface shape design method based on the partial compensation method described in the present invention can constrain the stroke of the deformable mirror, realize the design of the partial compensator of the deformable mirror, and meet the needs of high-precision free-form surface shape measurement.

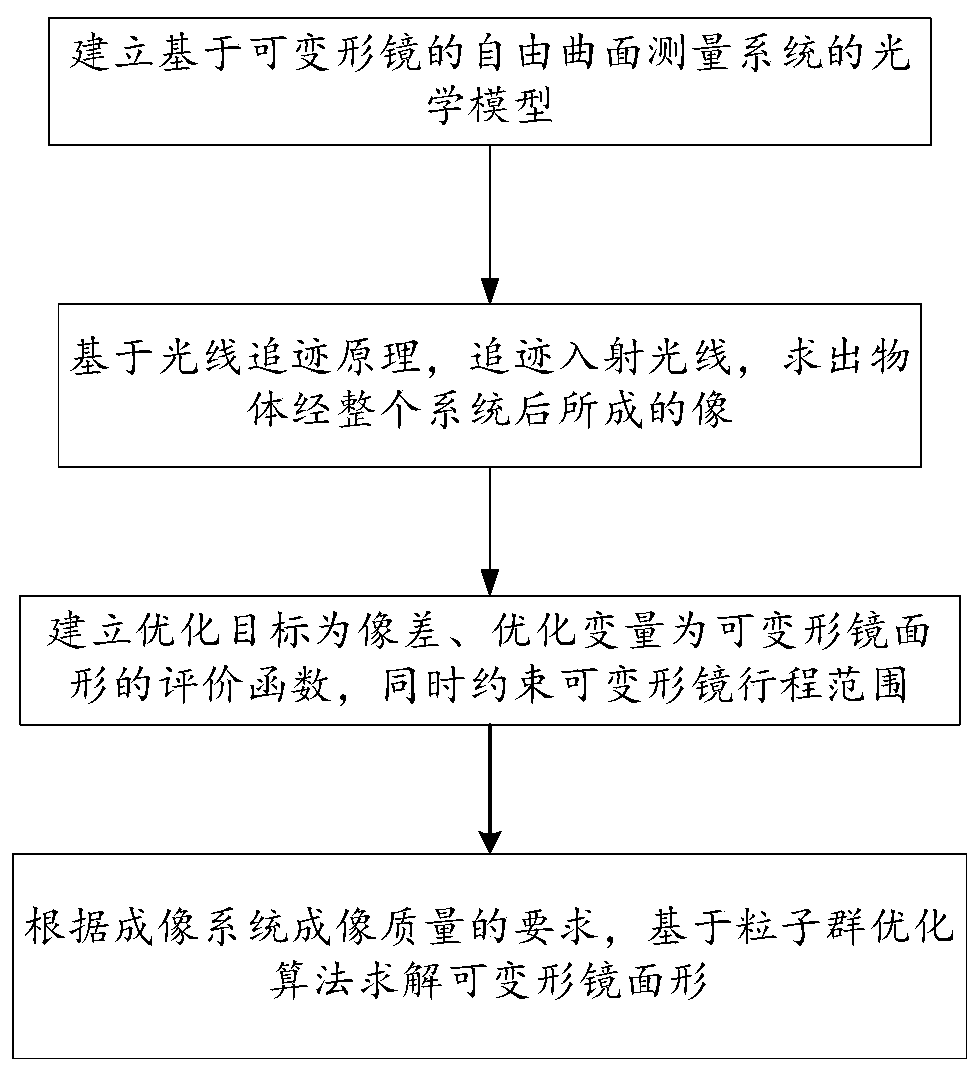

[0026] Such as figure 1 As shown, this deformable mirror shape design method for free-form surface measurement includes the following steps:

[0027] (1) Establish the optical model of the free-form surface measurement system b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com