Superconducting joint of NbTi and Nb3Sn superconducting wires and preparation method of superconducting joint

A technology of superconducting joints and superconducting wires, which is applied in the directions of superconducting magnets/coils, coil manufacturing, connecting contact materials, etc., can solve the problems of complex processes, the preparation method of Sn superconducting wire joints, and the large joint resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

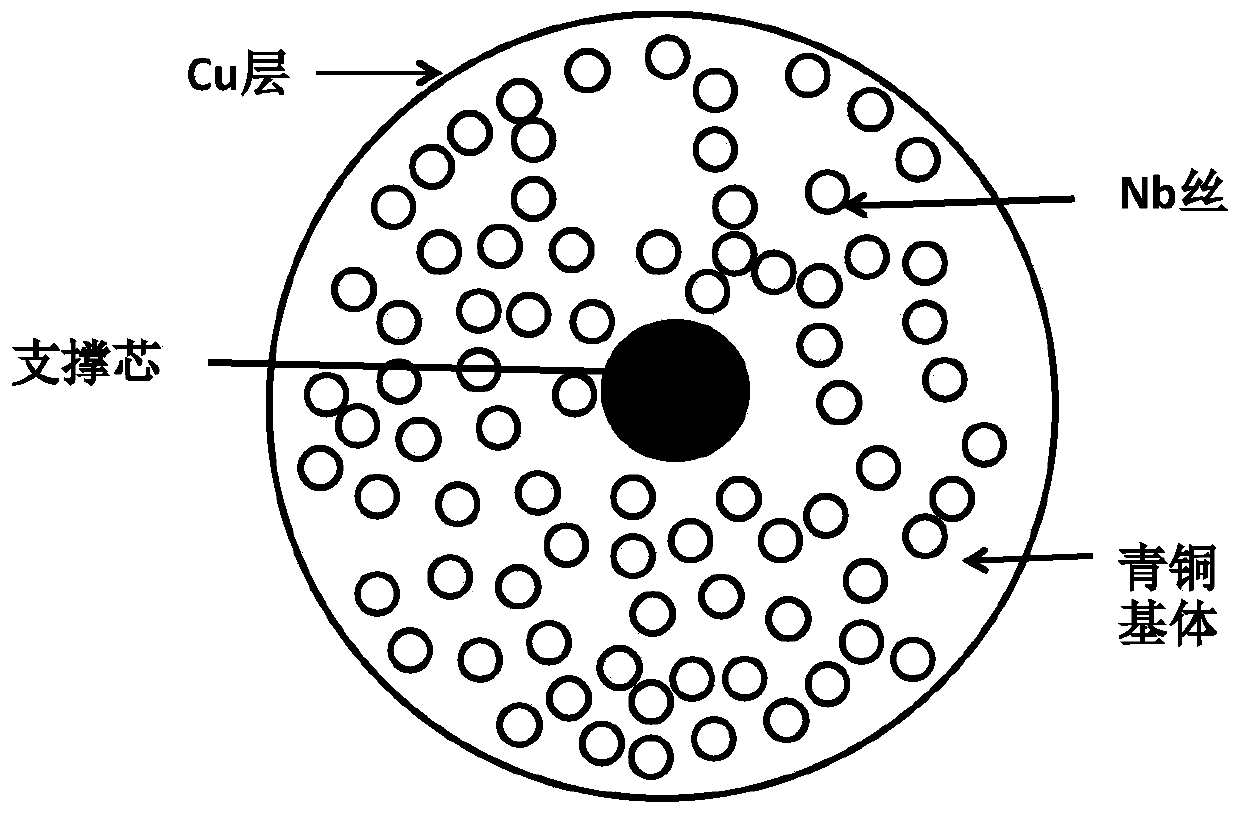

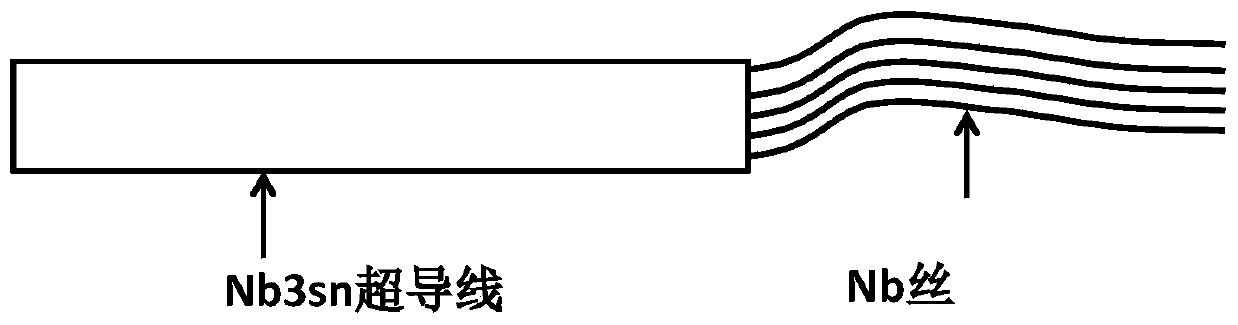

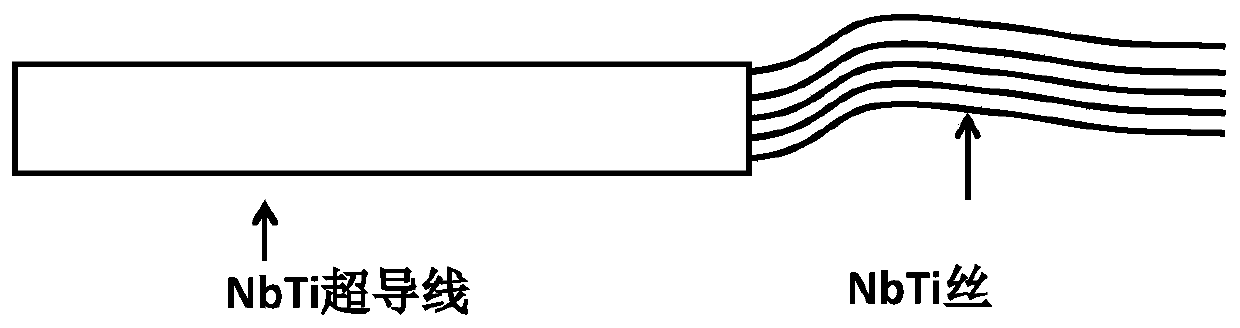

[0040] Corrosion of Nb with 50% nitric acid 3 The copper layer at the end of the Sn superconducting wire, the length of the corrosion section is 1cm, and the Nb is exposed 3 Nb filaments and supporting cores in Sn superconducting wires. Remove Nb 3 The support core at the end of the Sn superconducting wire, etched Nb with a mixed acid of 30% by volume nitric acid and 20% by volume hydrofluoric acid 3 For the Nb filaments at the ends of the Sn superconducting wires, clean the Nb filaments with deionized water, spread them out and blow them dry. The copper layer at the end of the NbTi superconducting wire is etched with nitric acid with a volume fraction of 50%, and the length of the etched section is 1 cm, exposing the NbTi wire in the NbTi superconducting wire. Corrode the NbTi wire at the end of the NbTi superconducting wire with a mixed acid of 30% nitric acid and 20% hydrofluoric acid by volume, clean the NbTi wire with deionized water, spread it out and blow dry. Inser...

Embodiment 2

[0042] Corrosion of Nb with 60% nitric acid 3 The copper layer at the end of the Sn superconducting wire, the length of the etched section is 10cm, and the Nb is exposed 3 Nb filaments and supporting cores in Sn superconducting wires. Remove Nb 3 The support core at the end of the Sn superconducting wire, etched Nb with a mixed acid of 70% by volume nitric acid and 5% by volume hydrofluoric acid 3 For the Nb filaments at the ends of the Sn superconducting wires, clean the Nb filaments with deionized water, spread them out and blow them dry. The copper layer at the end of the NbTi superconducting wire is etched with nitric acid with a volume fraction of 60%, and the length of the etched section is 10 cm, so as to expose the NbTi wire in the NbTi superconducting wire. Corrode the NbTi wire at the end of the NbTi superconducting wire with a mixed acid of 70% nitric acid and 5% hydrofluoric acid by volume, clean the NbTi wire with deionized water, spread it out and blow dry. I...

Embodiment 3

[0044] Corrosion of Nb with 55% nitric acid 3 The copper layer at the end of the Sn superconducting wire, the length of the corrosion section is 5cm, and the Nb is exposed 3 Nb filaments and supporting cores in Sn superconducting wires. Remove Nb 3 The support core at the end of the Sn superconducting wire is etched with a mixed acid of 50% nitric acid and 15% hydrofluoric acid by volume for Nb 3 For the Nb filaments at the ends of the Sn superconducting wires, clean the Nb filaments with deionized water, spread them out and blow them dry. The copper layer at the end of the NbTi superconducting wire is etched with nitric acid with a volume fraction of 55%, and the length of the etched section is 5 cm, exposing the NbTi wire in the NbTi superconducting wire. Corrode the NbTi wire at the end of the NbTi superconducting wire with a mixed acid of 50% nitric acid and 15% hydrofluoric acid by volume, clean the NbTi wire with deionized water, spread it out and blow dry. Insert th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com